Special high-flexibility cable for robots and manufacturing process thereof

A manufacturing process and special cable technology, applied in the direction of cable/conductor manufacturing, insulated cables, flexible cables, etc., can solve the problems of reduced service life, easy cracking of the outer skin, delamination, etc., to suppress the passage of electromagnetic waves and improve the resistance Interference performance, the effect of signal transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

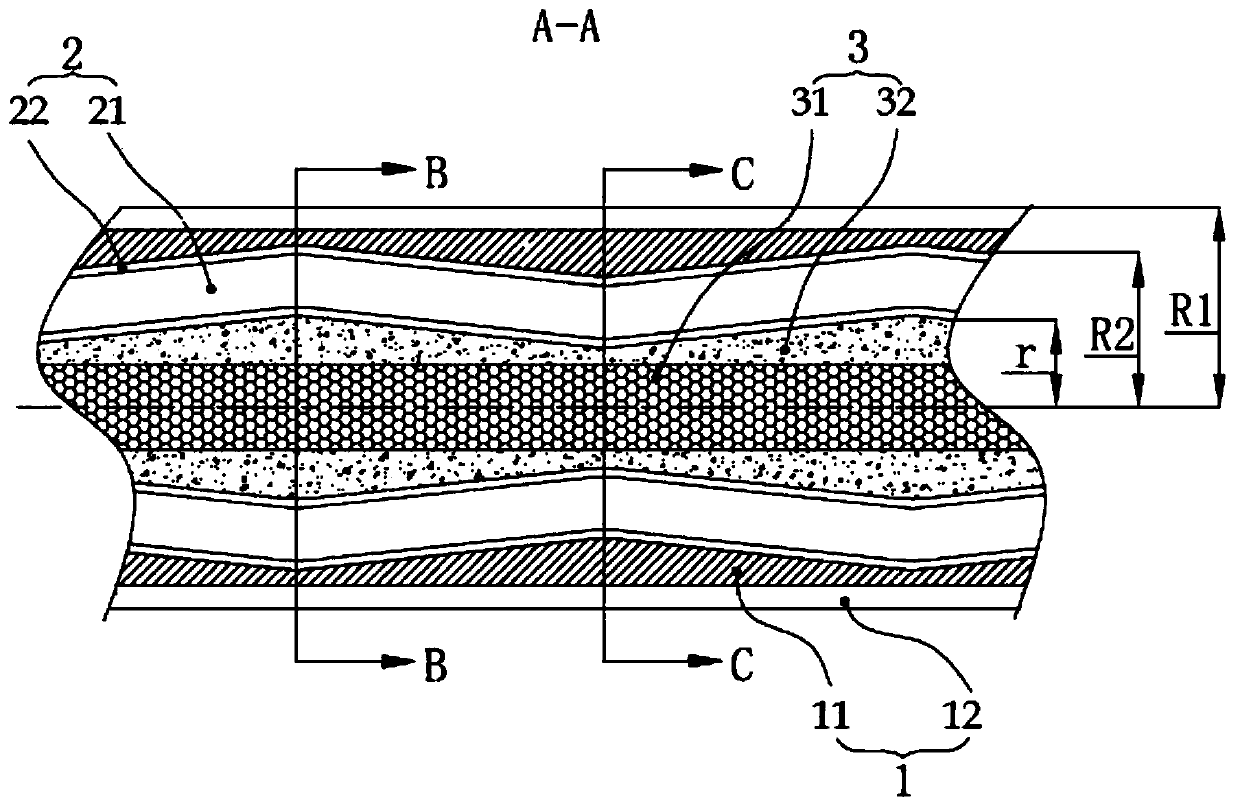

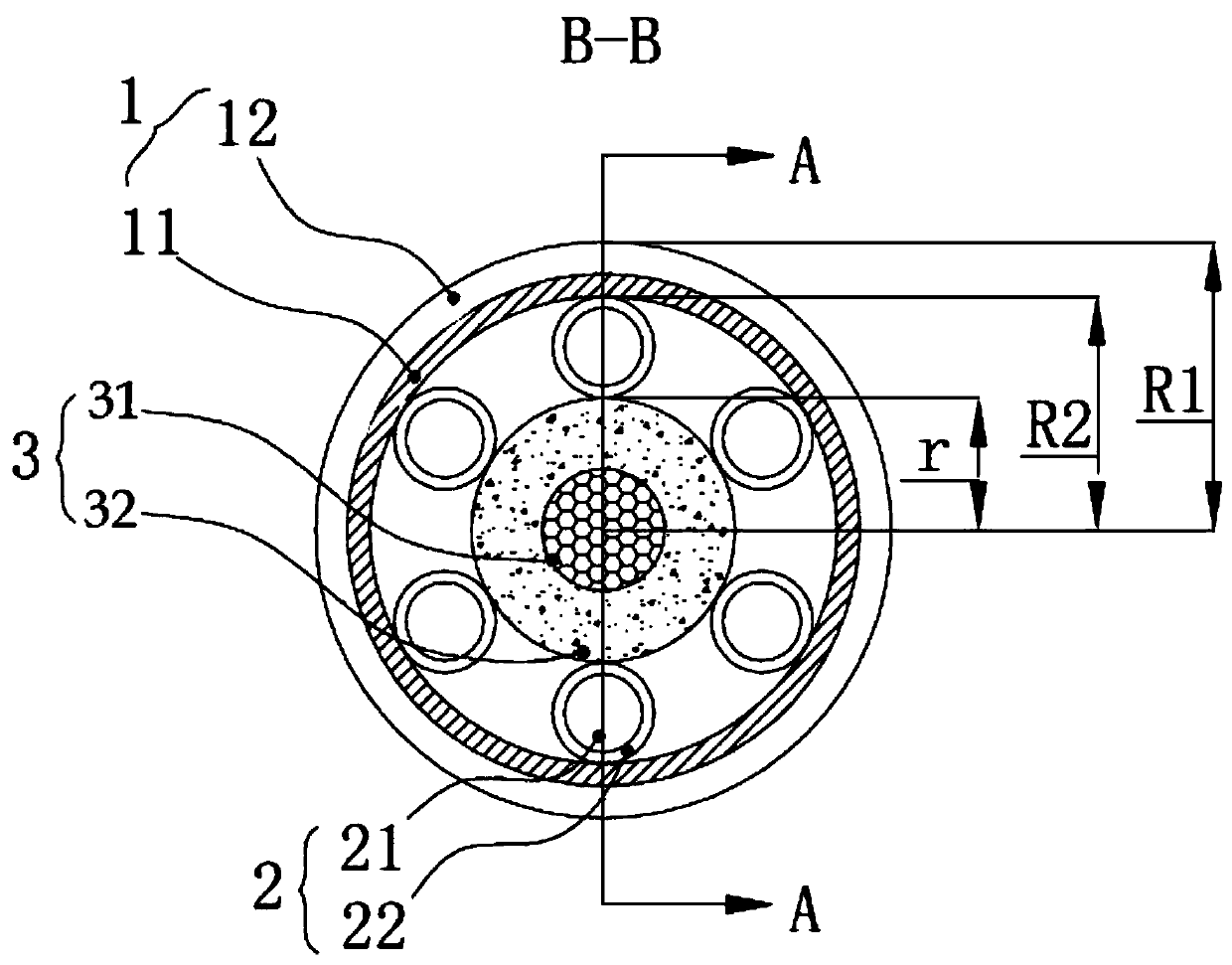

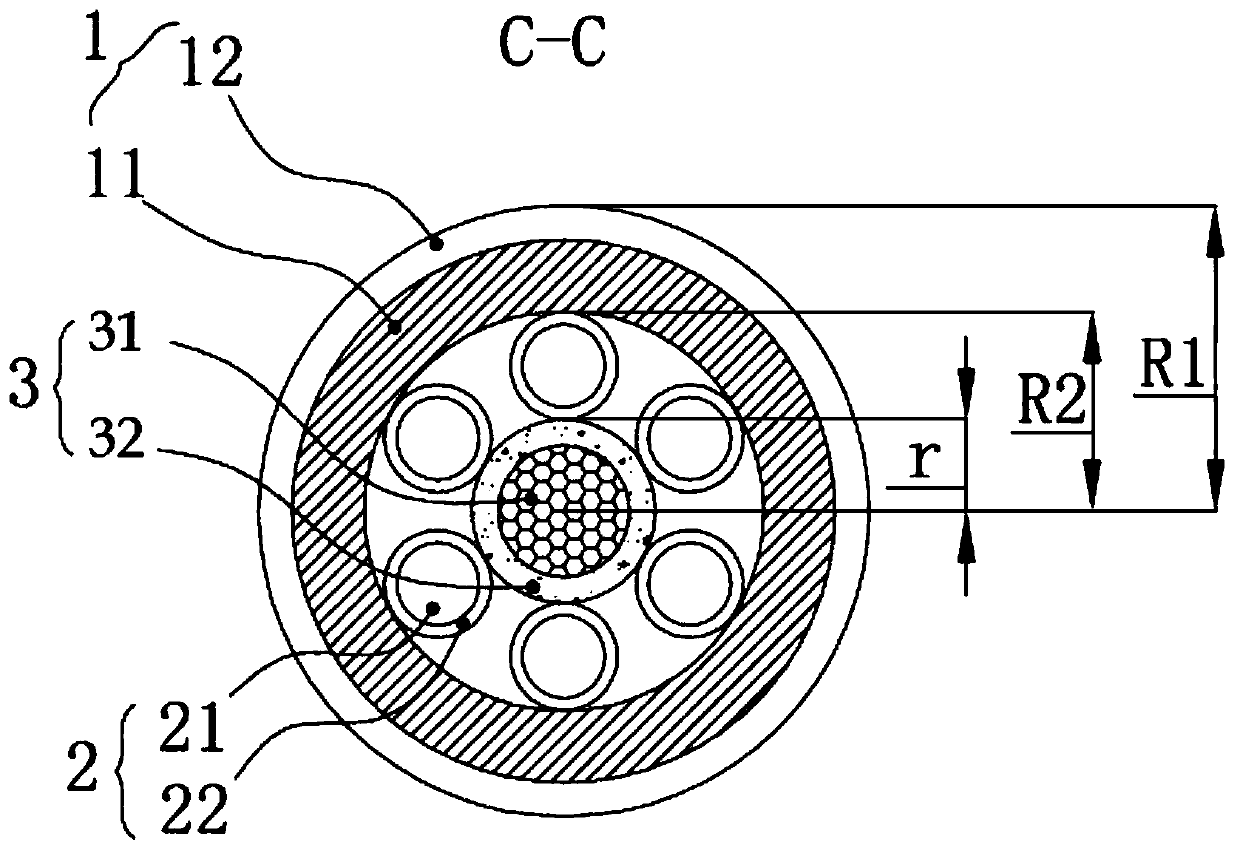

[0042] Such as Figure 1~4 As shown, a manufacturing process of a special cable for a high-flexibility robot uses a tubular outer sheath 1 to wrap multiple sets of wire cores 2 to obtain the above-mentioned special cable for a high-flexibility robot. A central body is arranged at the inner center of the outer sheath 1 3. The multiple groups of wire cores 2 are evenly distributed along the circumference of the central body 3; wherein, the central body 3 is obtained by wrapping the second insulating layer 31 on the surface of the aramid fiber 32, and the wire cores 2 are obtained by wrapping the second insulating layer 31 on the surface of the wire 22. An insulating layer 21 is obtained, and the preparation method of the outer sheath 1 is as follows:

[0043] (1) First knead sucrose polyester modified low-phenyl silicone rubber, isoprene rubber, fluorosilicone rubber, nitrile rubber, and organically modified wollastonite powder to make a mixture, and then add vulcanizing agent a...

Embodiment 2

[0058] Such as Figure 1~4 As shown, a manufacturing process of a special cable for a high-flexibility robot uses a tubular outer sheath 1 to wrap multiple sets of wire cores 2 to obtain the above-mentioned special cable for a high-flexibility robot. A central body is arranged at the inner center of the outer sheath 1 3. The multiple groups of wire cores 2 are evenly distributed along the circumference of the central body 3; wherein, the central body 3 is obtained by wrapping the second insulating layer 31 on the surface of the aramid fiber 32, and the wire cores 2 are obtained by wrapping the second insulating layer 31 on the surface of the wire 22. An insulating layer 21 is obtained, and the preparation method of the outer sheath 1 is as follows:

[0059] (1) First knead sucrose polyester modified low-phenyl silicone rubber, isoprene rubber, fluorosilicone rubber, nitrile rubber, and organically modified wollastonite powder to make a mixture, and then add vulcanizing agent a...

Embodiment 3

[0074] Such as Figure 1~4As shown, a manufacturing process of a special cable for a high-flexibility robot uses a tubular outer sheath 1 to wrap multiple sets of wire cores 2 to obtain the above-mentioned special cable for a high-flexibility robot. A central body is arranged at the inner center of the outer sheath 1 3. The multiple groups of wire cores 2 are evenly distributed along the circumference of the central body 3; wherein, the central body 3 is obtained by wrapping the second insulating layer 31 on the surface of the aramid fiber 32, and the wire cores 2 are obtained by wrapping the second insulating layer 31 on the surface of the wire 22. An insulating layer 21 is obtained, and the preparation method of the outer sheath 1 is as follows:

[0075] (1) First knead sucrose polyester modified low-phenyl silicone rubber, isoprene rubber, fluorosilicone rubber, nitrile rubber, and organically modified wollastonite powder to make a mixture, and then add vulcanizing agent an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com