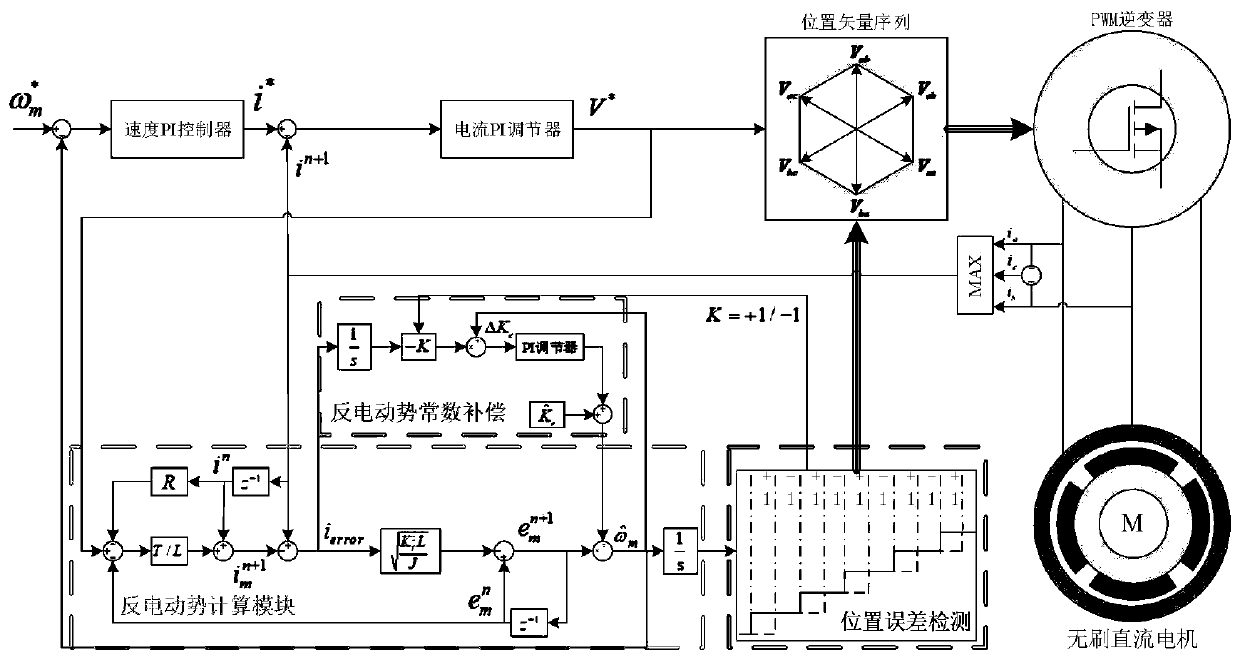

Position-free control system for compensating back electromotive force constant of brushless direct-current motor

A back electromotive force constant and back electromotive force technology, which is applied in the field of positionless control for compensating the back electromotive force constant of brushless DC motors, can solve problems such as reducing the performance of sensorless control algorithms, reduce torque ripple, improve accuracy, and improve The effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

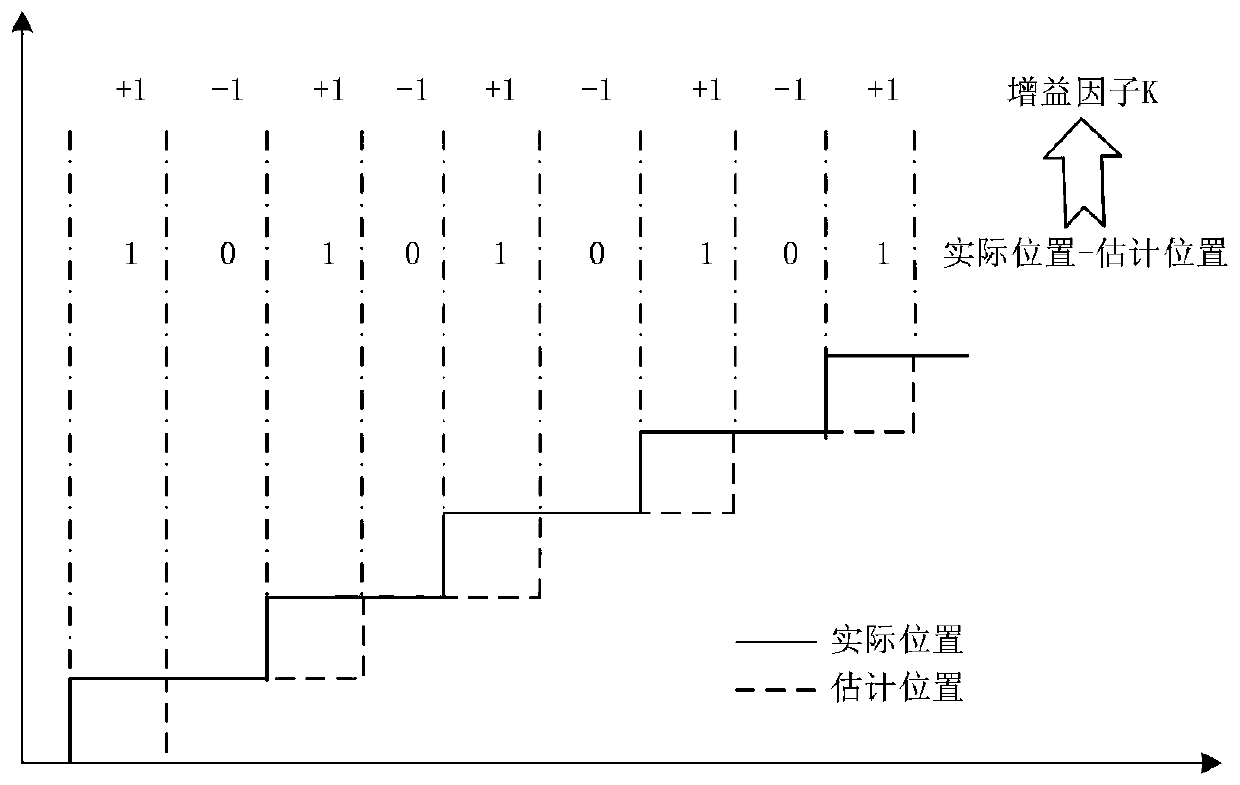

Method used

Image

Examples

Embodiment 1

[0105] In the embodiment, the parameters of the three-phase brushless DC motor are shown in the table below.

[0106]

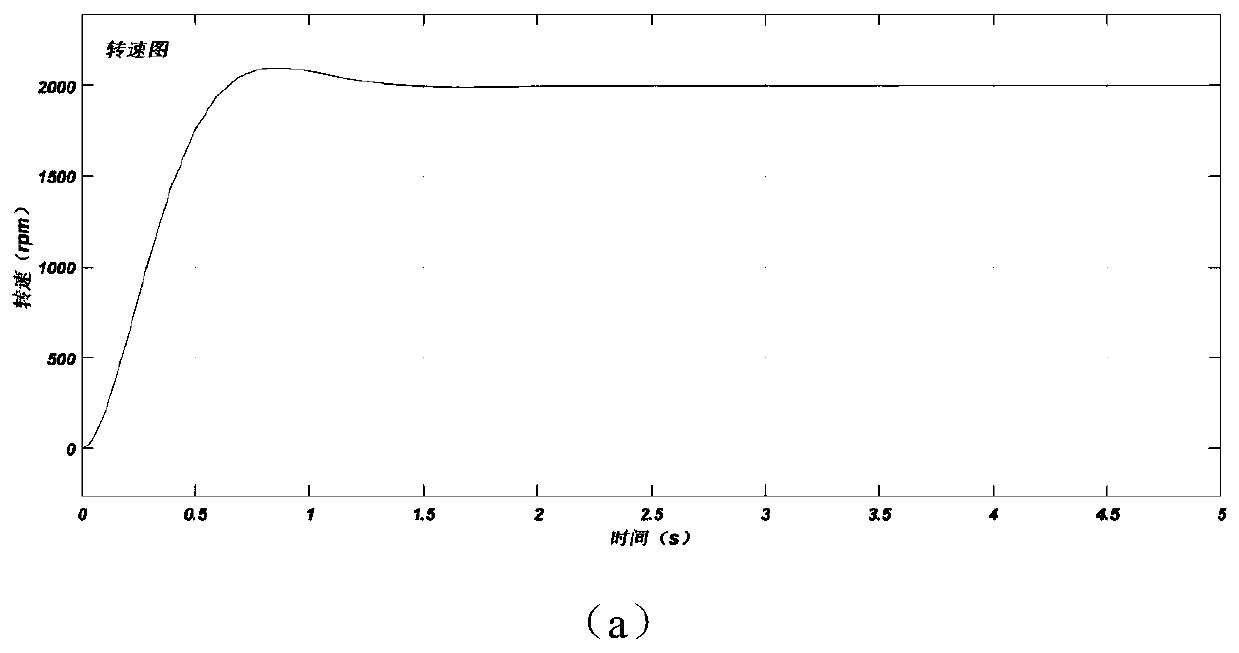

[0107] In this embodiment, the rated speed is set to 2000 RPM, the load torque is set to 0.1 N·m, and the sampling period and switching frequency are set to 10 kHz.

[0108] image 3 is the rotating speed and position waveform of the rotor (the new detection algorithm, the back EMF constant is unchanged), under this test condition, the back EMF algorithm adopts the new detection algorithm combining the voltage equation and the mechanical equation shown in formula (14), the back EMF The constant remains unchanged, and the back electromotive force constant compensation module is not introduced. image 3 (a) shows the rotational speed waveform, image 3 (b) and (c) show the waveforms of the estimated position of the rotor and the actual position. It can be seen that the difference is small, and the algorithm is verified.

[0109] Figure 4 is the rotor sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com