Preparation method of Ag2MoO4/Ag2O material for rapidly degrading malachite green

A malachite green, rapid degradation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve catalyst recovery troubles, complex synthesis steps, Environmental secondary pollution and other problems, to achieve the effect of short decolorization time, high reuse rate, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of Ag that rapidly degrades malachite green 2 MoO 4 / Ag 2 O material preparation method, comprises the following steps:

[0030] Preparation of Ag by hydrothermal method 2 MoO 4 / Ag 2 O complex, the specific operation is: in 20.0mL1.2M Na 2 MoO 4 2H 2 Add 0.1M Na to the beaker of O 2 HPO 4 12H 2 O 20mL, keep stirring for 5min, add 2.2mL HNO 3 , add 0.6M AgNO dropwise 3 10mL, continue to stir for 15min, slowly add 4M NaOH to pH = 7, let it stand for 15min, discard most of the supernatant, transfer about 20mL suspension to a 25mL autoclave lined with polytetrafluoroethylene, 120 React in a constant temperature box at ℃ for 14 hours, filter with suction, wash with pure water three times, transfer to a crucible, and dry in a constant temperature box at 80 °C for 12 hours for later use.

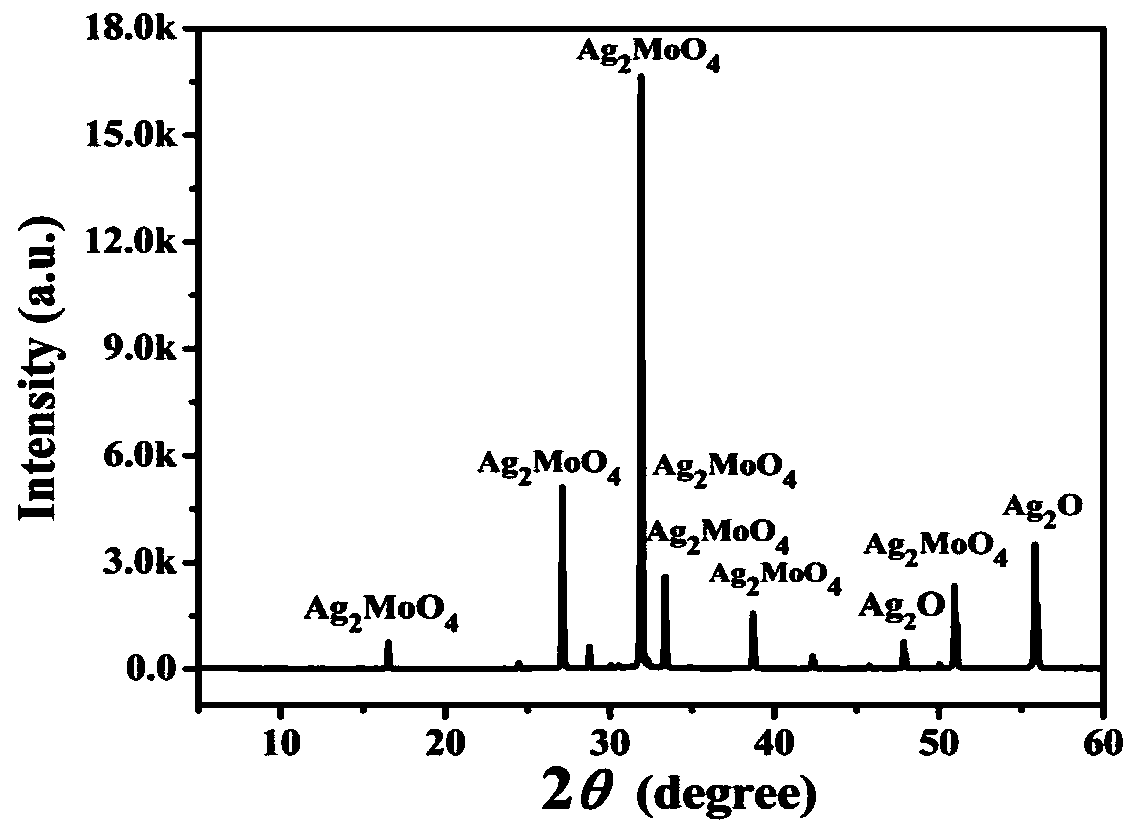

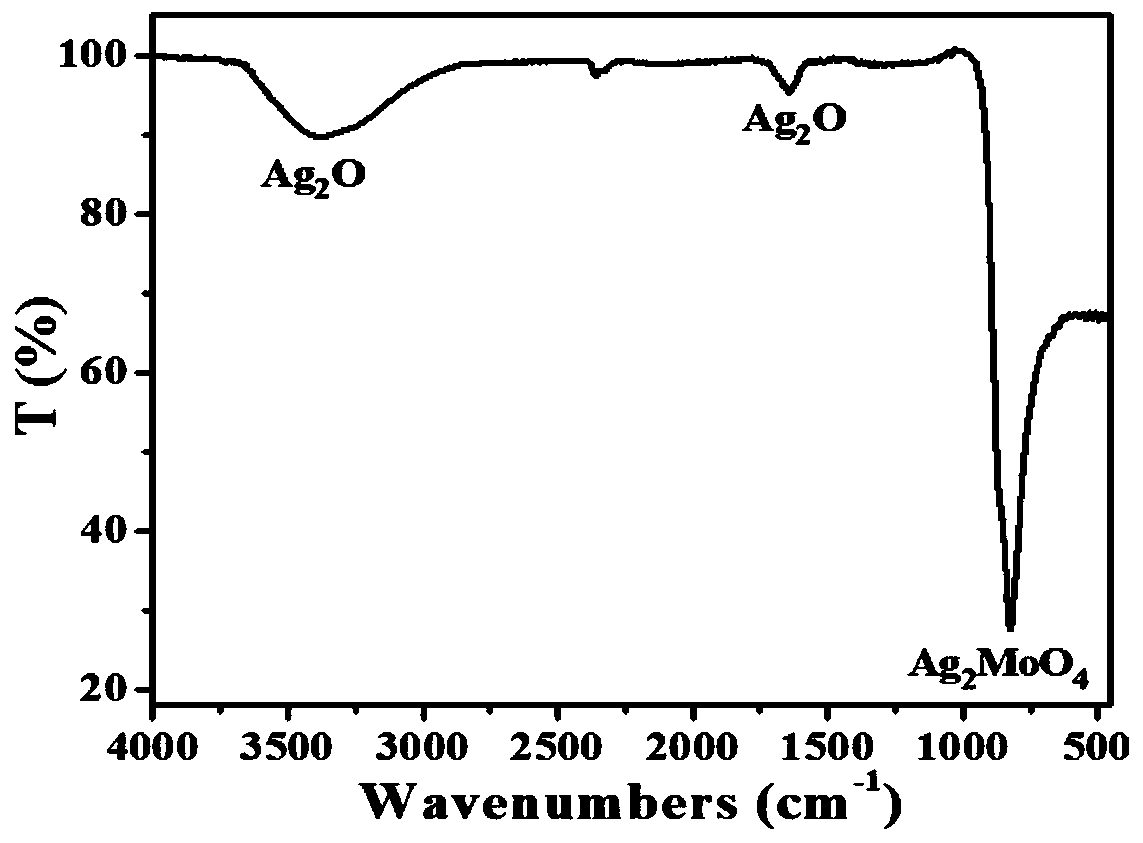

[0031] Depend on figure 1 It can be seen that the Ag obtained by the above preparation method 2 MoO 4 / Ag 2 XRD characterization results of O materials.

[0032] D...

Embodiment 2

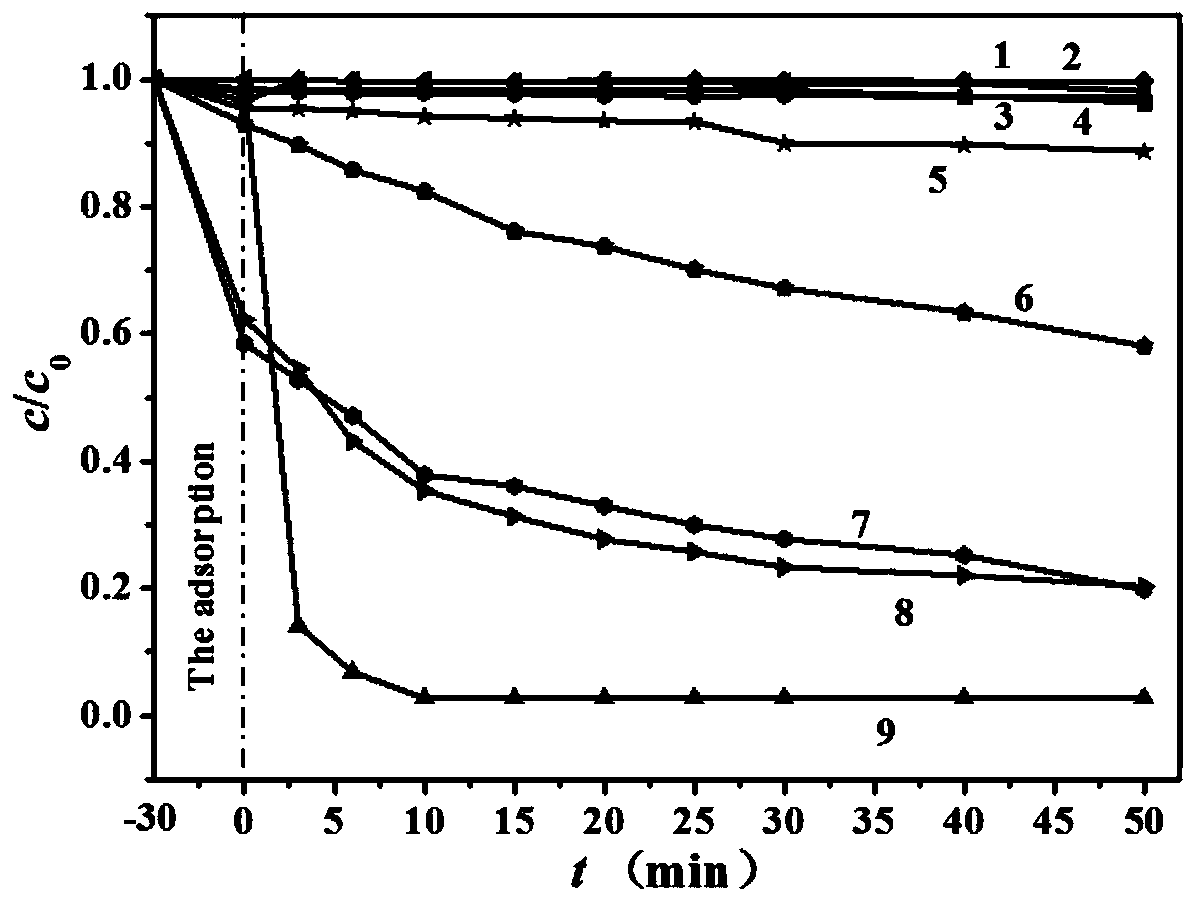

[0034] The silver-based Fenton heterogeneous catalyst prepared in Example 1 is applied to degrade MG in waste water, and the results are as follows image 3 , Figure 4 shown.

experiment example

[0043] In the traditional Fenton reaction, iron ions are not easy to recycle, resulting in secondary pollution. In this study, Ag 2 MoO 4 / Ag 2 The heterogeneous phase of O was recovered and the reuse rate determined. Depend on Figure 5 It can be seen that Ag 2 MoO 4 / Ag 2 The O catalyst binds H after performing 5 recycles 2 o 2 Degraded MG, the decolorization rate was 87.9% at 5min, 91.8% at 20min, and 93.6% at 40min, indicating that Ag 2 MoO 4 / Ag 2 O has good recycling performance and has a good application prospect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com