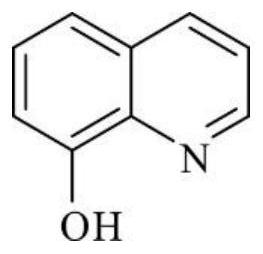

A kind of flotation collector of pitchblende and its application

A technology of pitchblende ore and collector, which is applied in flotation, solid separation, etc., can solve the problems of low economic benefit, high leaching acid consumption, and many harmful minerals, so as to improve the grade of uranium, reduce the amount of ore, and collect powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

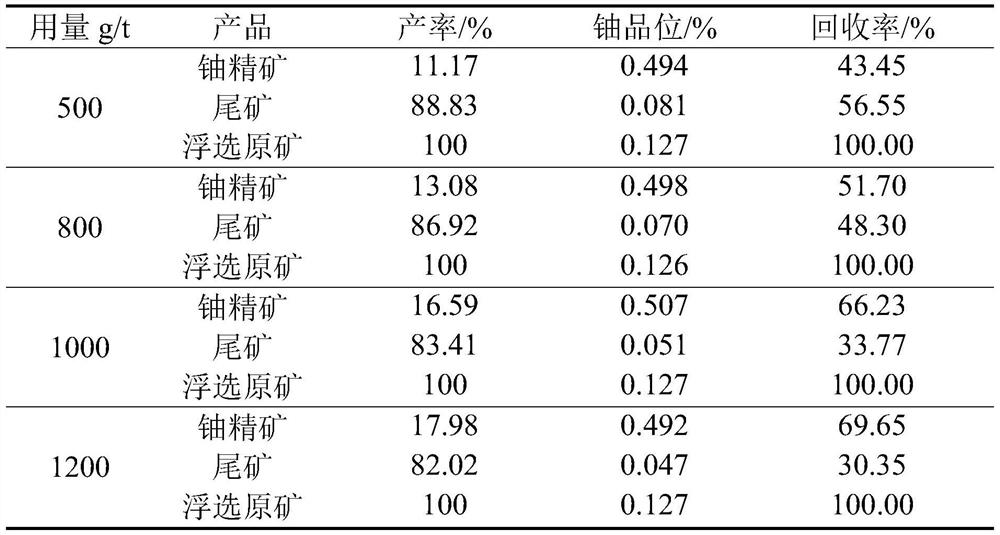

[0036] The uranium grade of a volcanic-type uranium deposit is 0.127%. The main uranium mineral is pitchblende, and the uranium mineral particles are fine. In addition, it also contains gangue minerals such as quartz, feldspar, neonite, and chlorite. After the ore was ground to -0.043mm particle size accounting for 70%, the flotation temperature of 28°C and the amount of foaming agent No. 2 oil was 150g / t, and the flotation of uranium under the condition of different amounts of collector 8-hydroxyquinoline The selection effect, the flotation process adopts a rough selection, and the test results are shown in Table 1.

[0037] Table 1 Test results of different dosage conditions of 8-hydroxyquinoline

[0038]

[0039] It can be seen from Table 1 that when the amount of 8-hydroxyquinoline is 500-2000g / t, a significant flotation effect can be obtained, and with the increase of the amount of 8-hydroxyquinoline, the recovery rate of uranium in the flotation concentrate increases ...

Embodiment 2

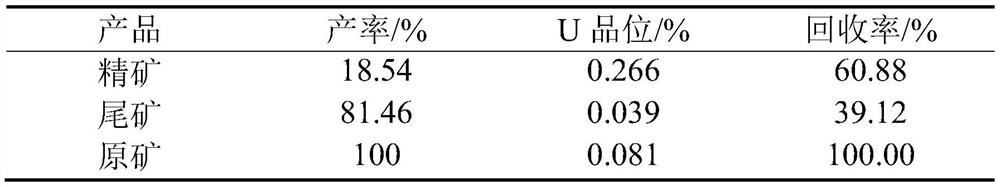

[0041] The main uranium mineral in a granite-type uranium deposit is pitchblende, and the gangue minerals are mainly quartz, potassium feldspar, plagioclase, biotite, pyroxene and hornblende, and contain a small amount of titanite, barite, zirconium stone. The uranium grade of the ore is 0.081%, and the direct leaching effect is poor, the processing capacity is large, and the economic benefit is poor. Using the 8-hydroxyquinoline described in the present invention as a collector, a laboratory flotation test was carried out on the ore. Add 1000g / t of the collector of the present invention during roughing, and stir for 5 minutes; add 200g / t of auxiliary collector isooctyl phosphate, and stir for 3 minutes; the amount of foaming agent MIBC is 100g / t, stir for 3 minutes and then inflate Flotation 5 ~ 8min. No agent is added during the selection, and the flotation is directly scraped after stirring for 1 to 3 minutes. The test results are shown in Table 2.

[0042] Table 2 Test r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com