Mo doped mn-fe-p-si based magnetic refrigeration material and preparation method thereof

A magnetic refrigeration material, cold water technology, applied in the direction of magnetic material, inorganic material magnetism, inductance/transformer/magnet manufacturing, etc., can solve the problems of unfavorable material practical application, poor mechanical stability and fragile, weakening material mixed magnetic properties, etc., to achieve optimization Magnetocaloric effect, low cost, optimized Curie temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

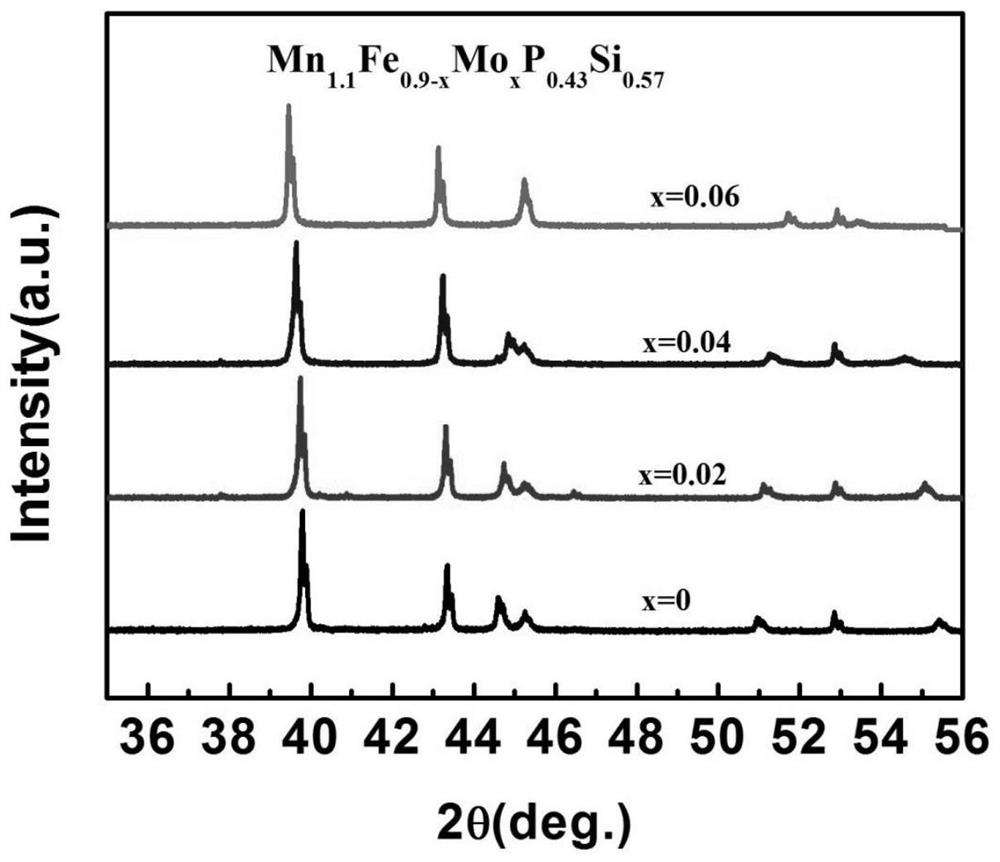

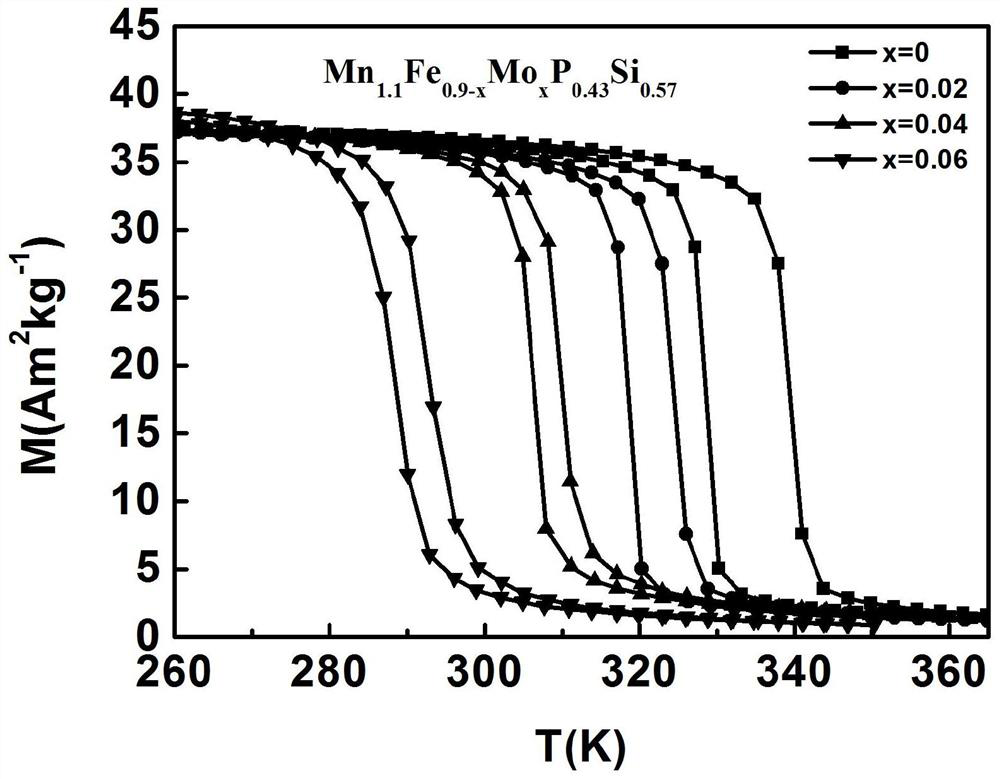

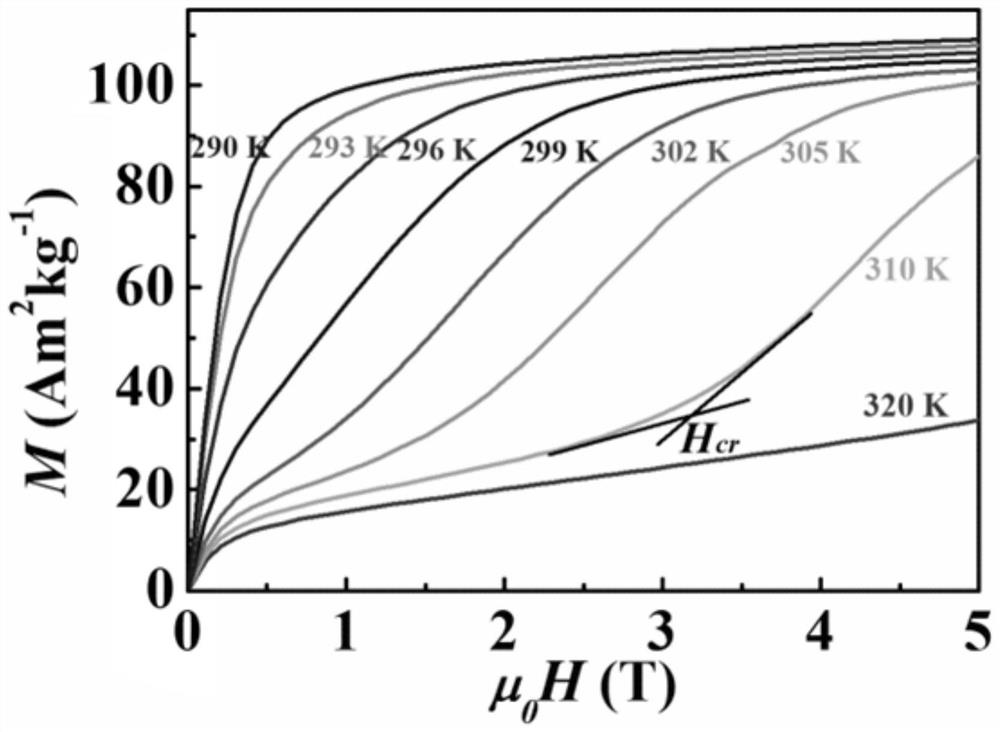

[0021] (1) Manganese flakes, iron powder, molybdenum powder, phosphorus block, silicon block according to Mn 1.1 Fe 0.88 Mo 0.02 P 0.43 Si 0.57 (X=0.02) The molar ratio of the alloy is weighed, and put into a stainless steel ball mill jar for ball milling under the protection of argon. The ball milling process conditions are: the mass ratio of steel balls to raw materials is 6:1, the ball milling time is 10 hours, and the frequency is 30 Hz;

[0022] (2) Put the ball-milled powder into a mold with a diameter of 10mm, and press it under a pressure of 750MPa to form The disc-shaped sample, the pressing time is 5min.

[0023] (3) Seal the pressed sample into a quartz tube under vacuum conditions, sinter at 1100° C. for 40 hours, and then quench in cold water to obtain a sample.

Embodiment 2

[0025] It was prepared by a method similar to that of Example 1, except that the molar ratio among Mn, Fe, Mo, P, and Si was changed to 1.1:0.86:0.04:0.43:0.57, that is, X=0.04, the rest were the same.

Embodiment 3

[0027] Prepared by a method similar to that of Example 1, except that the molar ratio among Mn, Fe, Mo, P, and Si is changed to 1.1:0.84:0.06:0.43:0.57, that is, X=0.06, the rest are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com