Synchronous short-cut denitrification-partial nitrosation-anaerobic ammonia oxidation system and method for sewage

An anaerobic ammonium oxidation and short-range denitrification technology, which is applied in the field of sewage treatment, can solve the problems of difficult to reach the standard of total nitrogen in effluent, unstable operation of anaerobic ammonium oxidation, and poor ability to withstand hydraulic shocks, so as to optimize the habitat of functional bacteria, The effect of reducing the loss rate of bacteria and improving the removal rate of total nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

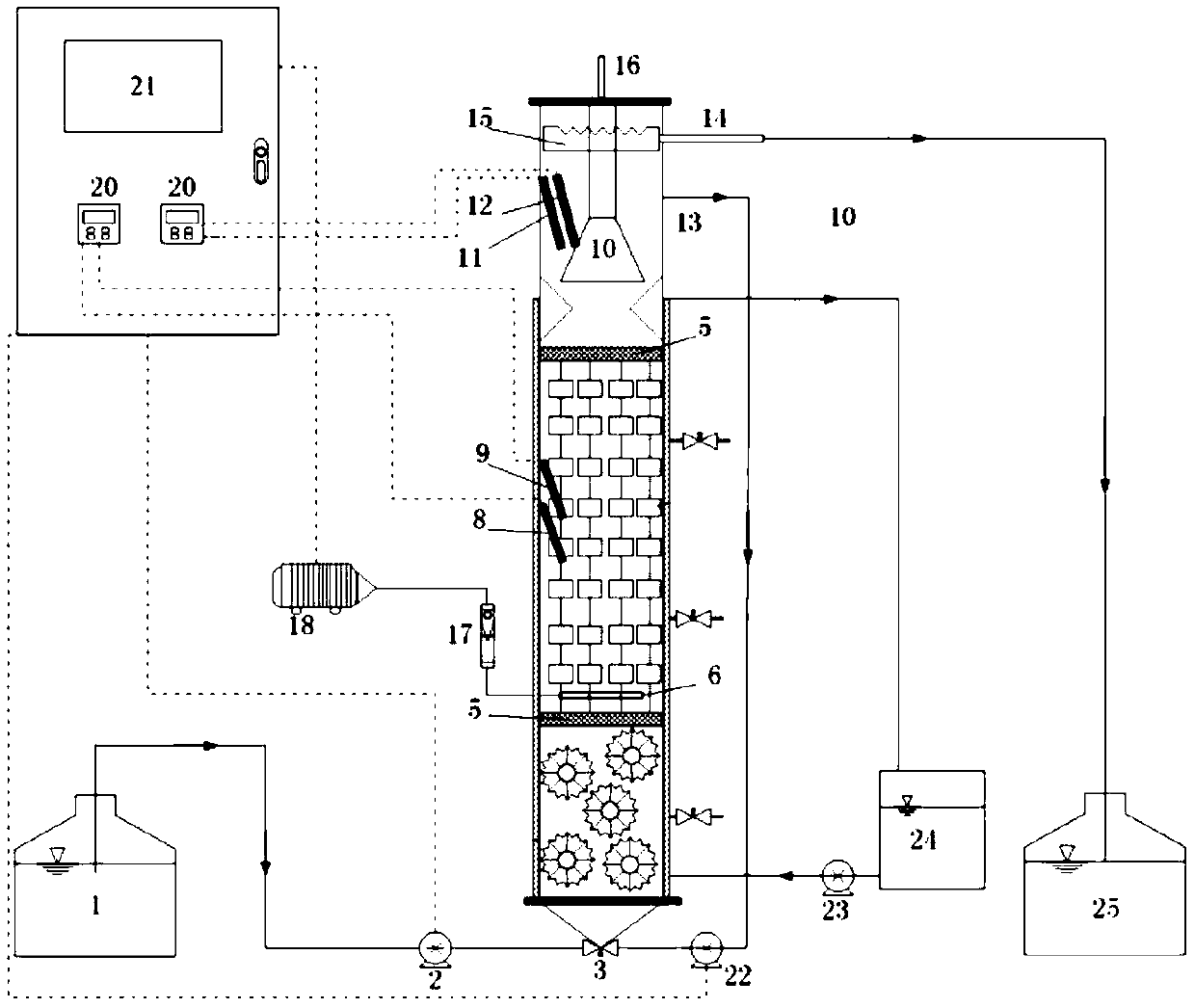

[0032] A simultaneous short-range denitrification-partial nitrosation-anammox system, its structure is as follows figure 1 As shown, it includes a raw water tank 1, a reactor, a PLC automatic control device, an aeration device, and an outlet water tank 25;

[0033] The reactor consists of three connected parts, from bottom to top are short-range denitrification zone, partial nitrification-anammox zone and three-phase separation zone; A first partition 5 is provided between the top of the denitrification zone and the bottom of the partial nitrosation-anammox zone, and the top of the partial nitrosation-anammox zone is connected to the bottom of the three-phase separation zone through a second partition 26. The gas discharge pipe of the phase separator 10 is connected to the water seal, there is a suspended filler in the short-range denitrification zone, and a filler bracket is provided in the partial nitrosation-ANAMMOX zone, filled with polyurethane foam bioactive filler, and ...

Embodiment 2

[0041] A method for synchronous short-range denitrification-partial nitrosation-ANAMMOX of sewage, which uses the synchronous short-range denitrification-partial nitrosation-ANAMMOX system of embodiment 1, comprising the following steps:

[0042] S1. Add sludge rich in short-range denitrifying bacteria to the short-range denitrification zone, and the concentration of inoculated sludge is 3000-6000mg / L; add rich ammonia-oxidizing bacteria and For the sludge of anammox bacteria, the concentration of inoculated sludge is 2000-4000mg / L;

[0043] S2. Make the sewage enter the short-range denitrification zone from the bottom of the short-range denitrification zone, and open the backflow port (13) at the same time, so that the reflux liquid and sewage containing nitrate nitrogen fully react with the inoculation sludge in the short-range denitrification zone, and the nitrification Convert state nitrogen into nitrite nitrogen and remove organic matter in water at the same time;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com