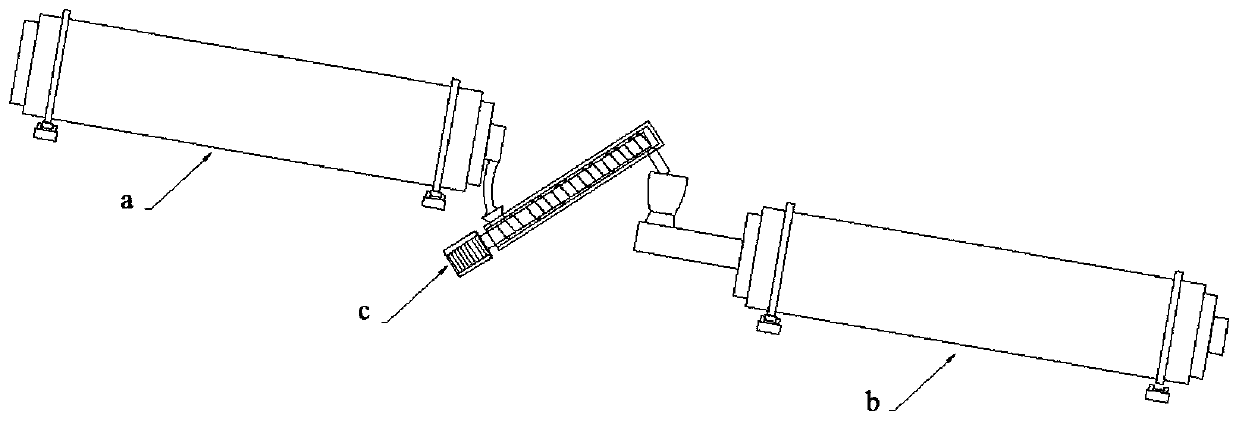

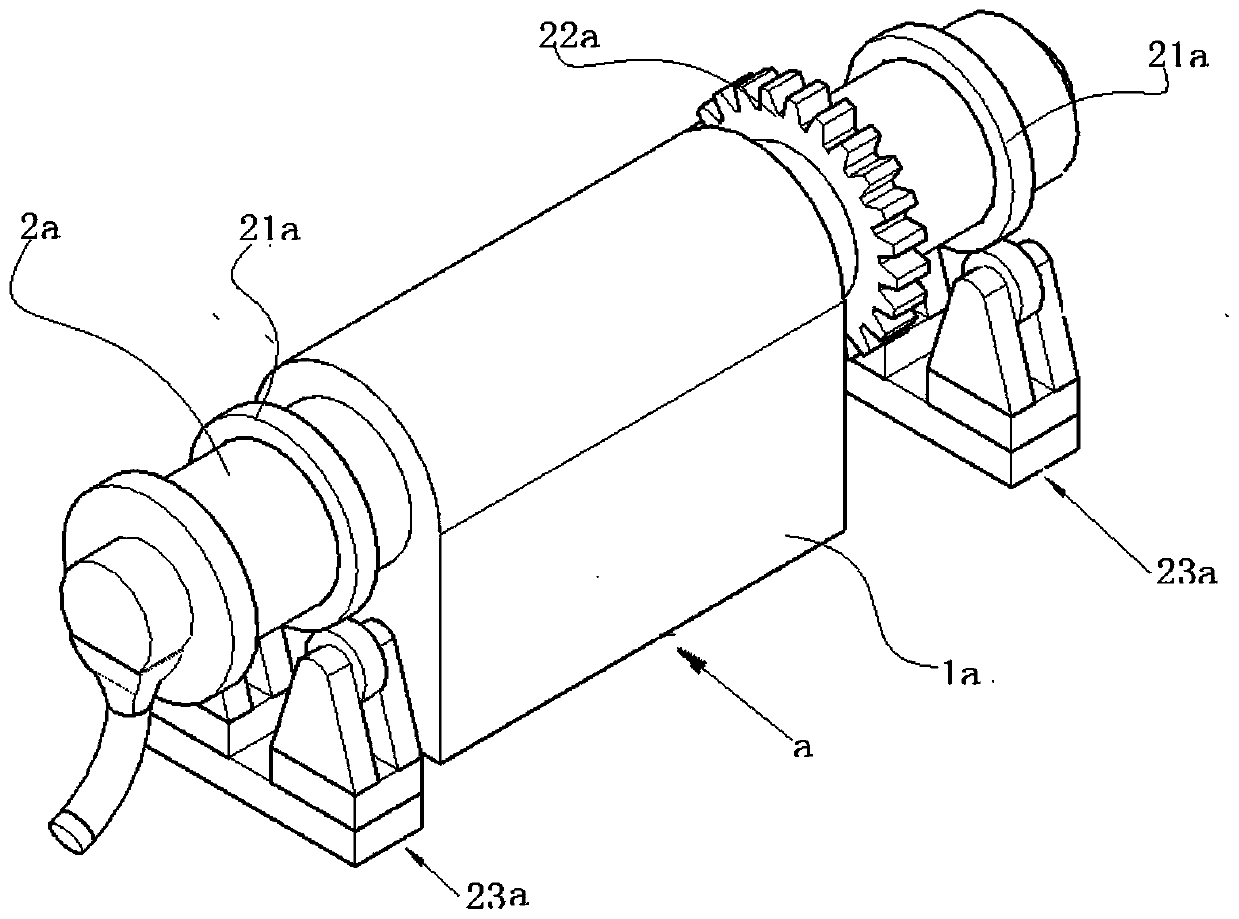

Sludge drying-carbonization combined heat treatment equipment

A heat treatment equipment and sludge drying technology, applied in dehydration/drying/concentrated sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of insufficient sludge drying, high cost of process equipment, and easy clogging of sludge, etc. problem, to achieve the effect of increasing the effect of heat treatment, increasing the effect of carbonization, and avoiding the effect of wrapping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0151] Carbonized material experiment:

[0152] The equipment disclosed in the present invention is used to treat 10 batches of the same materials as conventional heat treatment sludge equipment on the market.

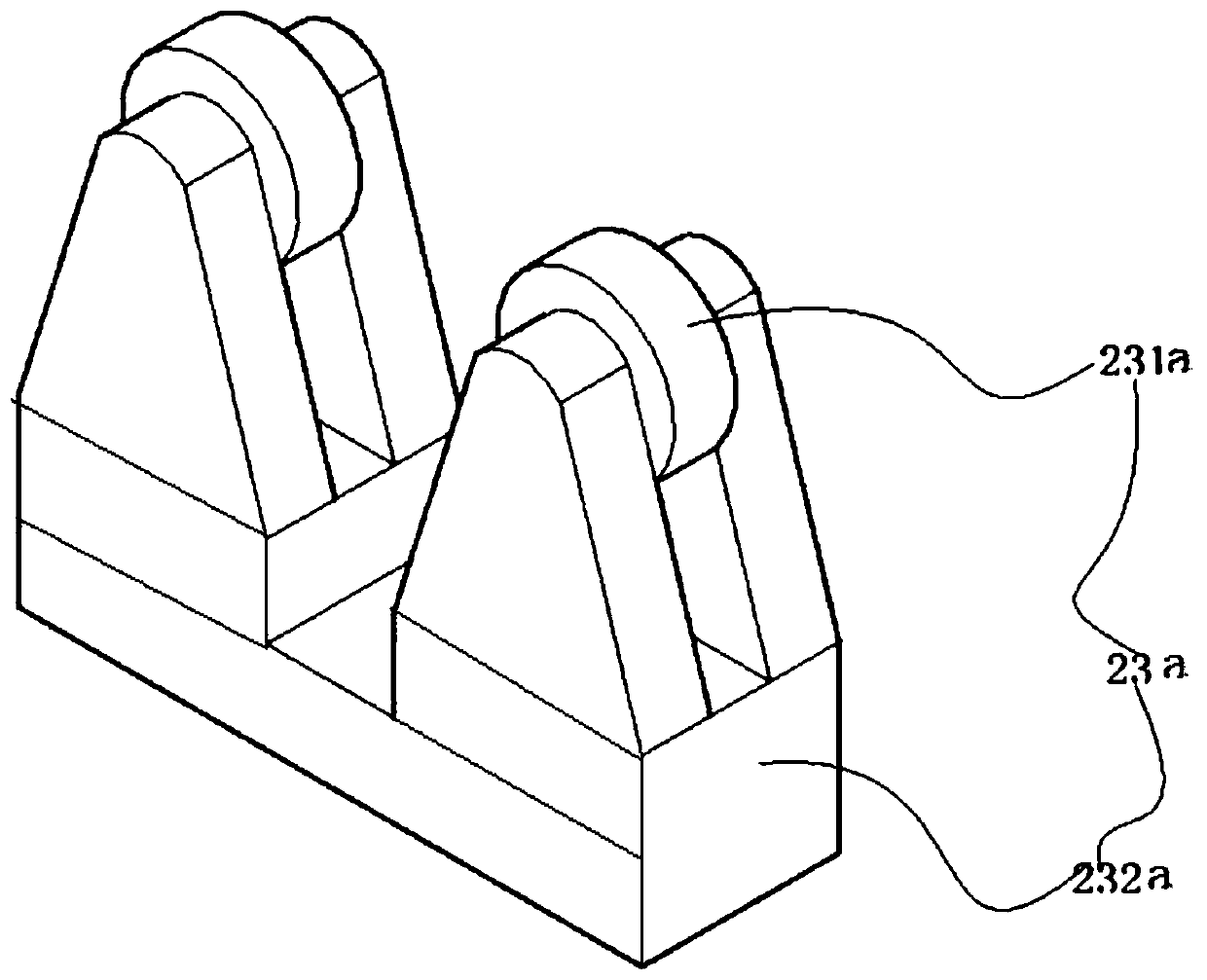

[0153] Specifically, the difference between the conventional heat treatment sludge equipment on the market and the equipment disclosed in the present invention is that there is no scrap assembly 25a in the drying furnace, no baffle plate 233b and the first copy plate 231b, the second Two copying boards 232b, the processing parameters are as shown in table 1:

[0154] Table 1

[0155]

[0156] It can be seen from Table 1 that:

[0157] 1. Using the equipment disclosed in the present invention, the amount of heat-treated sludge per unit time is obviously improved, and the production efficiency is significantly improved;

[0158] 2. After the sludge material is heat-treated by the equipment disclosed in the present invention, the specific surface area of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com