PVC foamed ceiling and preparation method thereof

A technology for ceiling and PVC resin powder, applied in the field of PVC ceiling and its preparation, can solve the problems of cracking and yellowing, unstable optical effect, short service life, etc., and achieve the effects of high cost performance, service life of arbitrary cutting and processing, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

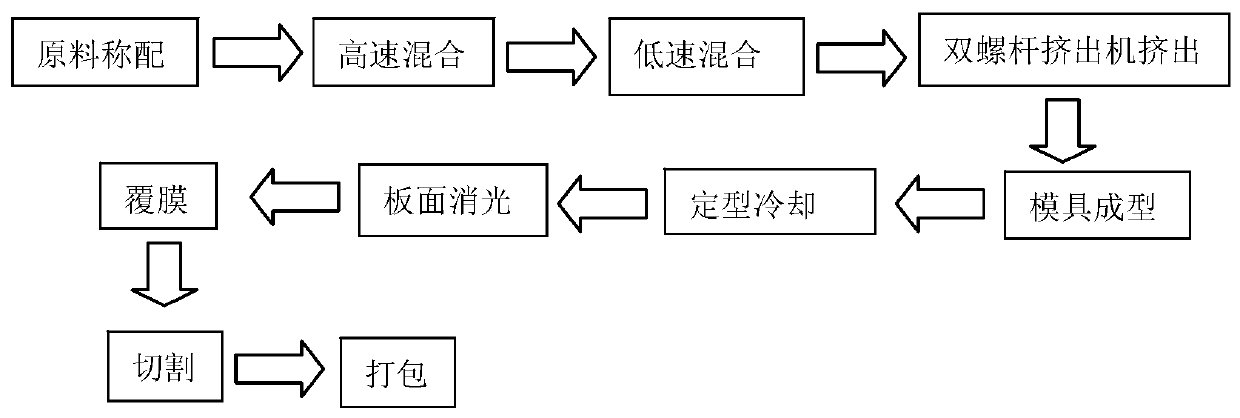

Method used

Image

Examples

Embodiment 1

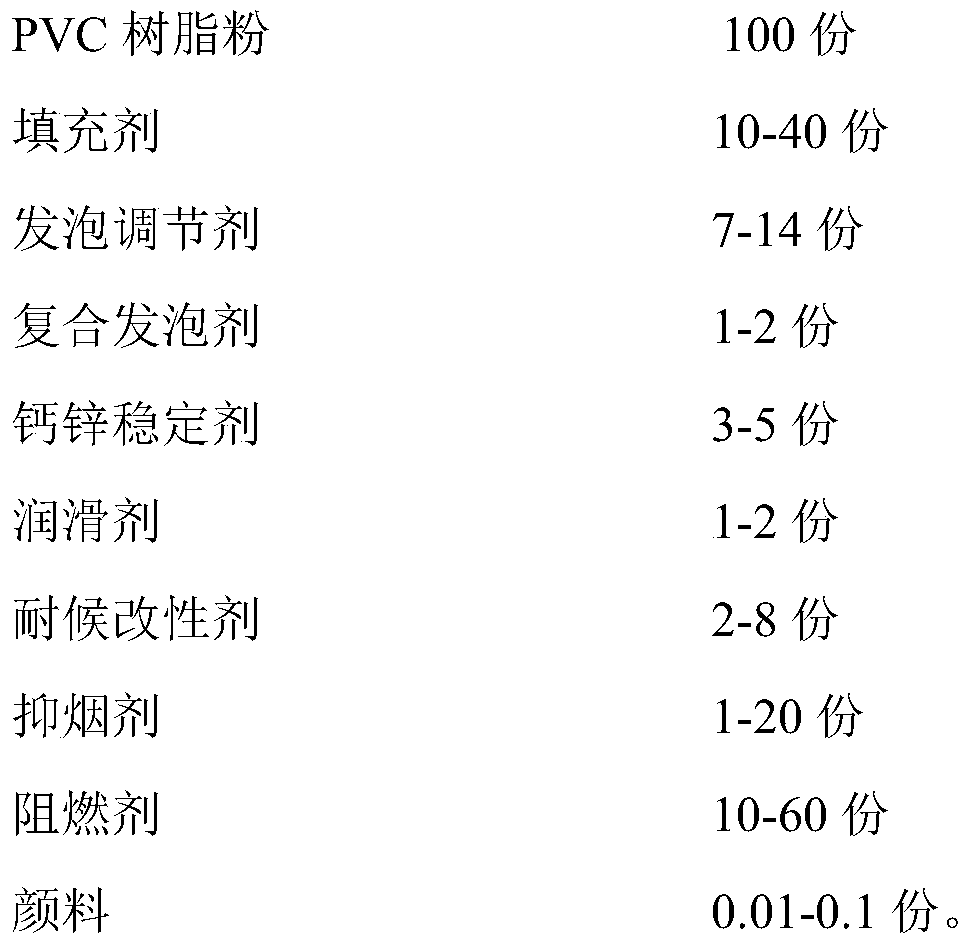

[0024] The PVC foam ceiling is made of the following raw materials in parts by weight:

[0025]

[0026] The PVC resin powder is a compound of SG-5 and SG-8; the PVC resin powder SG-5 is a powder with an average degree of polymerization of 1000, and the PVC resin powder SG-8 is a powder with an average degree of polymerization of 700. The mass ratio of SG-8 and SG-5 is 3:1;

[0027] The filler is heavy calcium carbonate with a particle size of 900 mesh.

[0028] The flame retardant is a boron-based flame retardant, a silicon-based flame retardant and a metal compound; the mass ratio of which is 30% of the boron-based flame retardant, 50% of the silicon-based flame retardant, and 20% of the metal compound.

[0029] The smoke suppressant is a composite of ammonium octamolybdate and metal oxide; the metal oxide includes zinc oxide and magnesium oxide. Among them, ammonium octamolybdate accounts for 80%, and zinc oxide and magnesium oxide each account for 10%.

[0030] Compo...

Embodiment 2

[0045] The PVC foam ceiling is made of the following raw materials in parts by weight:

[0046]

[0047] The PVC resin powder is a compound of SG-5 and SG-8; the PVC resin powder SG-5 is a powder with an average degree of polymerization of 1000, and the PVC resin powder SG-8 is a powder with an average degree of polymerization of 700. The mass ratio of SG-8 and SG-5 is 3:1;

[0048] The filler is heavy calcium carbonate with a particle size of 900 mesh.

[0049] The flame retardant is a boron-based flame retardant, a silicon-based flame retardant and a metal compound; the mass ratio of which is 30% of the boron-based flame retardant, 50% of the silicon-based flame retardant, and 20% of the metal compound.

[0050] The smoke suppressant is a composite of ammonium octamolybdate and metal oxide; the metal oxide includes zinc oxide and magnesium oxide. Among them, ammonium octamolybdate accounts for 80%, and zinc oxide and magnesium oxide each account for 10%.

[0051] Compo...

Embodiment 3

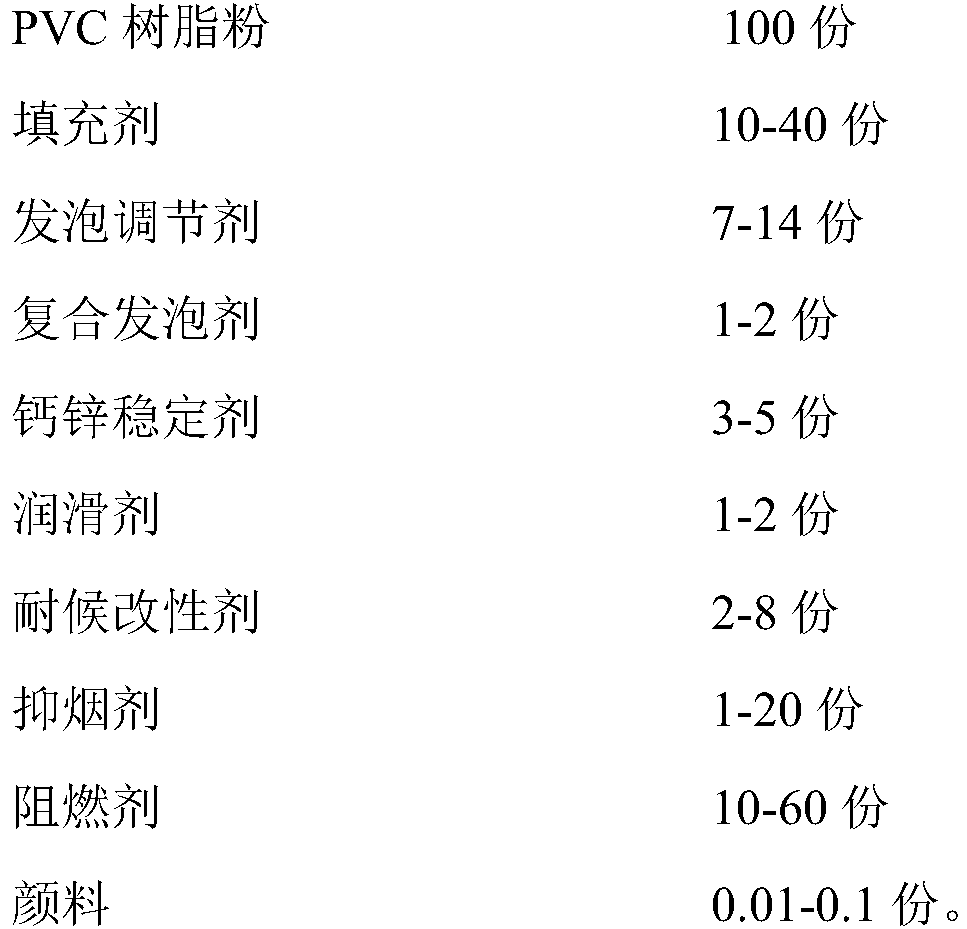

[0066] The PVC foam ceiling is made of the following raw materials in parts by weight:

[0067]

[0068]

[0069] The PVC resin powder is a compound of SG-5 and SG-8; the PVC resin powder SG-5 is a powder with an average degree of polymerization of 1000, and the PVC resin powder SG-8 is a powder with an average degree of polymerization of 700. The mass ratio of SG-8 and SG-5 is 3:1;

[0070] The filler is heavy calcium carbonate with a particle size of 900 mesh.

[0071] The flame retardant is a boron-based flame retardant, a silicon-based flame retardant and a metal compound; the mass ratio of which is 30% of the boron-based flame retardant, 50% of the silicon-based flame retardant, and 20% of the metal compound.

[0072] The smoke suppressant is a composite of ammonium octamolybdate and metal oxide; the metal oxide includes zinc oxide and magnesium oxide. Among them, ammonium octamolybdate accounts for 80%, and zinc oxide and magnesium oxide each account for 10%.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com