Method for detecting water dispersibility of basalt fiber wet-process chopped strands

A technology of basalt fiber and chopped strands, which is used in measuring devices, analytical materials, optical testing flaws/defects, etc., can solve the problems of human error, cannot objectively and accurately reflect the fiber dispersion level, etc., to reduce errors and shorten the Detection time, effect of high water dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

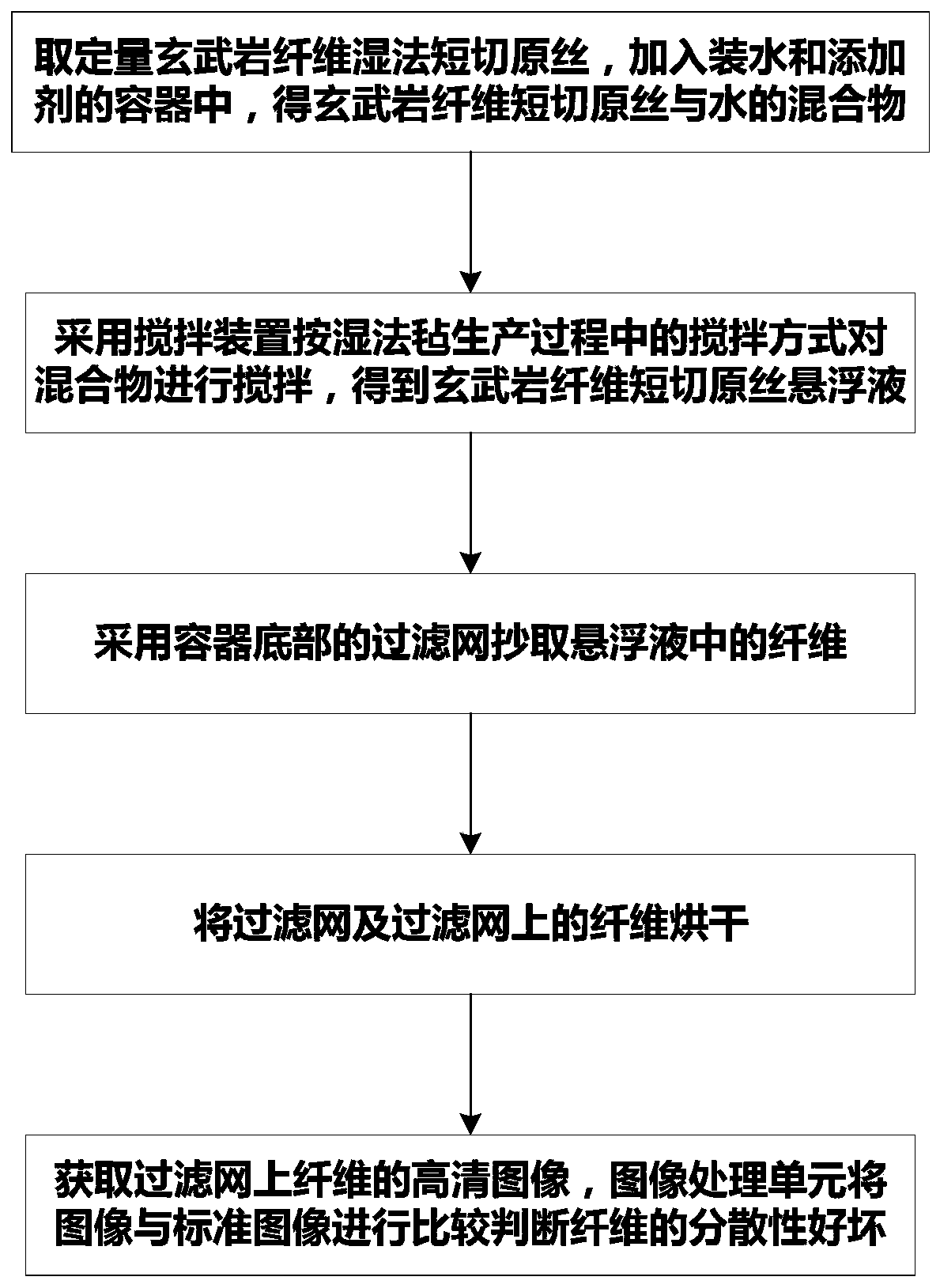

[0035] Such as figure 1 Shown, a kind of water dispersibility detection method of basalt fiber wet-process chopped strand, comprises the steps:

[0036] Take quantitative basalt fiber wet-process chopped strands and add them to the container for water and additives. The proportions of basalt fiber wet-process chopped strands, water and additives are reduced in the same proportion as the preparation process of basalt fiber wet-process mat to obtain basalt fiber wet-process chopped strands Mixture with water; use a stirring device to stir the mixture according to the stirring method in the production process of wet-laid felt. During the stirring process, do not interfere with the stirring process artificially. During the stirring process, the production process of wet-laid felt must be completely restored to obtain basalt fiber chopped raw Silk suspension, after the stirring is completed, remove the stirring device, use the horizontal filter screen preset at the bottom of the co...

Embodiment 2

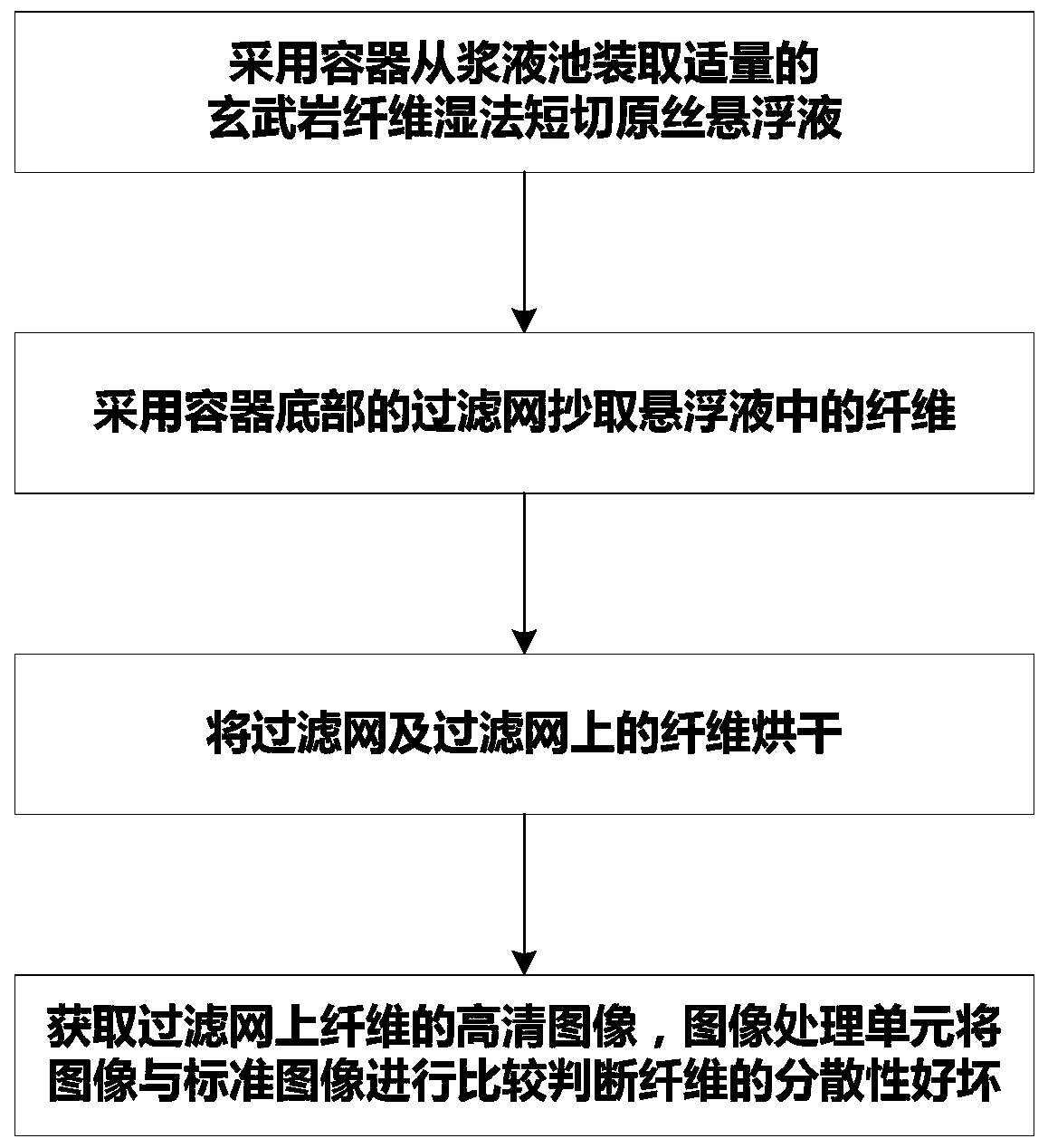

[0048] Such as figure 2 Shown, a kind of water dispersibility detection method of basalt fiber wet-process chopped strand, comprises the steps:

[0049] Use a container to load an appropriate amount of basalt fiber wet chopped strand suspension from the slurry tank, use the horizontal filter screen preset at the bottom of the container to move vertically upwards to pick up the fibers in the suspension, the filter screen is preset at the bottom of the container, and lift the filter screen Copy the fibers in the suspension to reduce the vibration caused by the filter when it is put into the suspension and affect the suspension, and at the same time avoid the fiber sticking to the bottom of the filter during the process of putting the filter, causing judgment errors, and at the same time copy smoothly Take the fiber in the suspension, try to ensure the state of the fiber after monofilamentization, and reduce the error introduced; the filter screen is a filter screen for papermak...

Embodiment 3

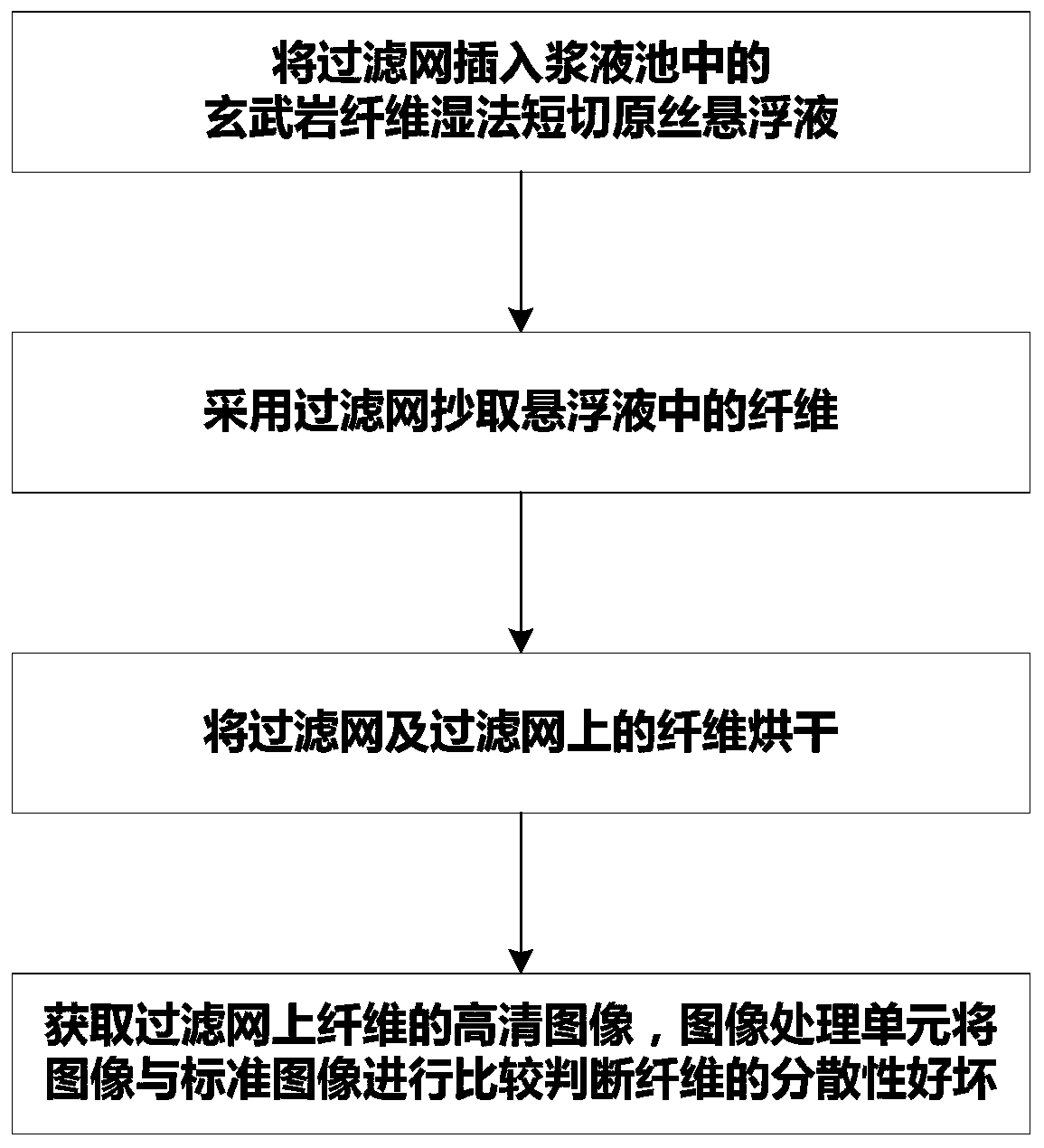

[0060] Such as image 3 Shown, a kind of water dispersibility detection method of basalt fiber wet-process chopped strand, comprises the steps:

[0061] Insert the filter screen into the basalt fiber wet-process chopped strand suspension in the slurry tank to a certain depth, and adjust the filter screen so that the screen surface is parallel to the slurry surface to reduce the uneven fiber distribution caused by the angle between the screen surface and the slurry surface. Then move the distance of at least one filter screen horizontally on the depth to reduce the influence of fiber redistribution on the picked fibers due to the filter screen extending into the suspension, and finally move the filter screen vertically upwards to pick up the fibers in the suspension; At the same time, the fibers in the suspension are smoothly picked up to ensure the state of the monofilamented fibers as much as possible and reduce the introduction of errors; the filter is a filter for papermaki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com