A kind of preparation method and application of two-dimensional lead iodide flakes

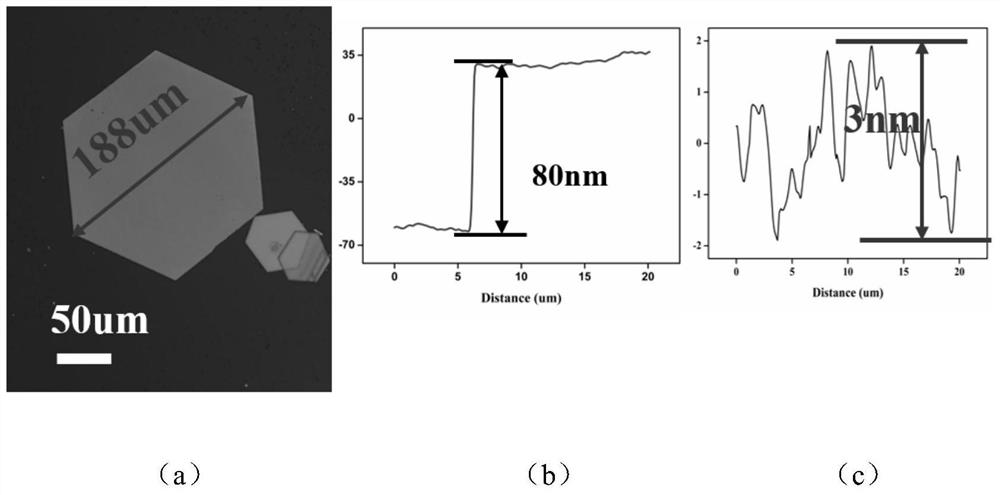

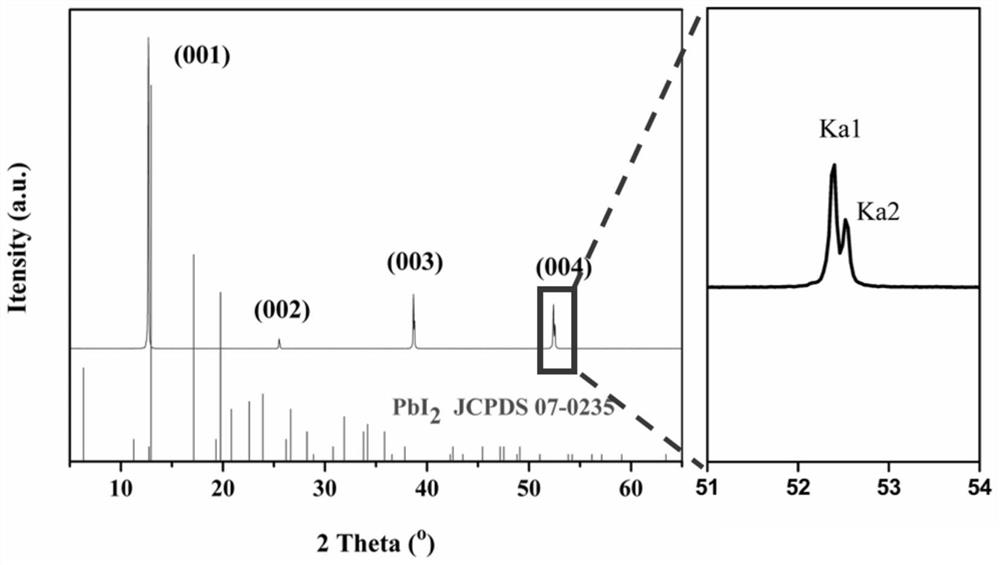

A lead iodide and flake technology is applied in the field of preparation of lead iodide nanomaterials, and can solve the problems of insufficient size of two-dimensional lead iodide, low yield of two-dimensional nanosheets, rough crystal surface, etc. The effect of high crystal quality and improved device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

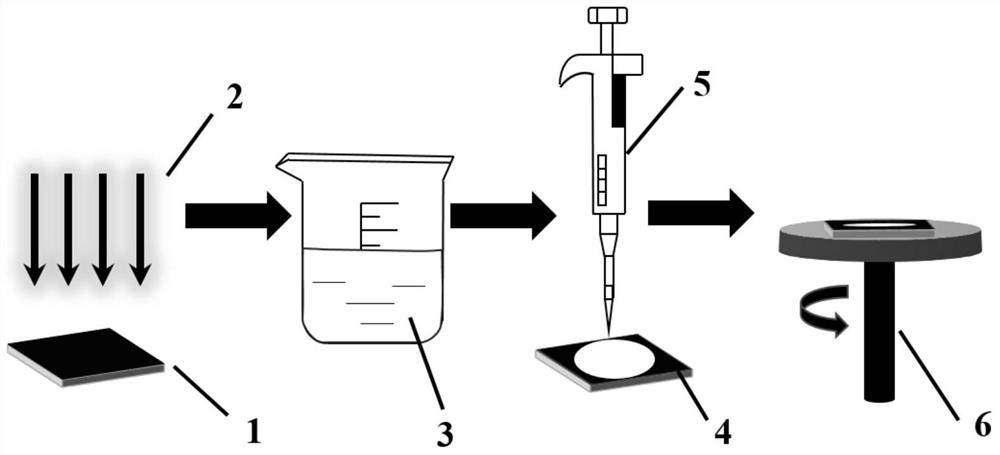

[0034] Cut the silicon wafer with 285nm silicon dioxide into several square pieces of 1cm×1cm, wash and dry it for later use. The cleaned silicon wafer was cleaned for 180 s with a 50W plasma degumming machine, and 100 μL of supersaturated lead iodide aqueous solution (2 mg / mL) was dropped on the treated silicon wafer. The silicon wafer with the lead iodide solution was spin-coated on a spin coater at a speed of 300r / min for 30s, and then the sample was dried at 25°C to obtain a two-dimensional lead iodide flake.

Embodiment 2

[0036] Cut the silicon wafer with 285nm silicon dioxide into several square pieces of 1cm×1cm, wash and dry it for later use. The cleaned silicon wafer was cleaned for 120 s with a 180W plasma degumming machine, and 50 μL of supersaturated lead iodide aqueous solution (2 mg / mL) was dropped onto the treated silicon wafer. The silicon wafer with the lead iodide solution was spin-coated on a spin coater at a speed of 300r / min for 30s, and then the sample was dried at 25°C to obtain a two-dimensional lead iodide flake.

Embodiment 3

[0038] Cut the silicon wafer with 285nm silicon dioxide into several square pieces of 1cm×1cm, wash and dry it for later use. The cleaned silicon wafer was cleaned with a 400W plasma degumming machine for 60 s, and 300 μL of supersaturated lead iodide aqueous solution (4 mg / mL) was dropped on the treated silicon wafer. The silicon wafer with the lead iodide solution was spin-coated on a spin coater at a speed of 1000r / min for 20s, and then the sample was dried at 50°C to obtain a two-dimensional lead iodide flake.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com