Heap thermal desorption treatment system for repairing organic contaminated soil

A technology of organic pollution and treatment system, applied in the field of contaminated site remediation, can solve the problems of unsuitable pollution distribution and scattered contaminated soil remediation, low heating temperature of contaminated soil, etc., and achieves the effects of easy operation, simple composition and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that these drawings are not necessarily drawn to scale.

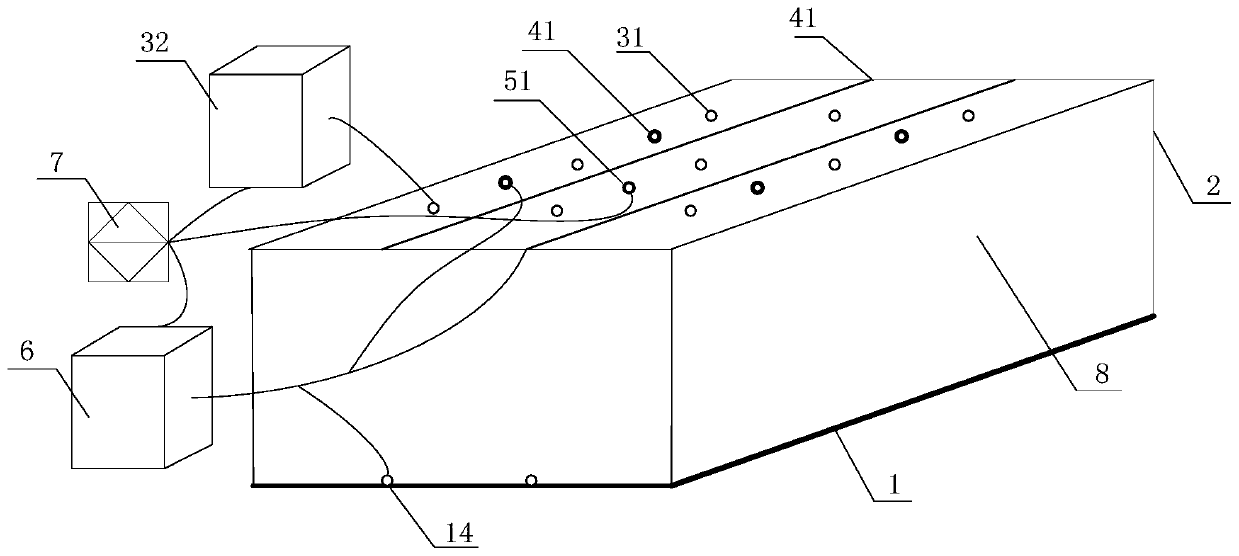

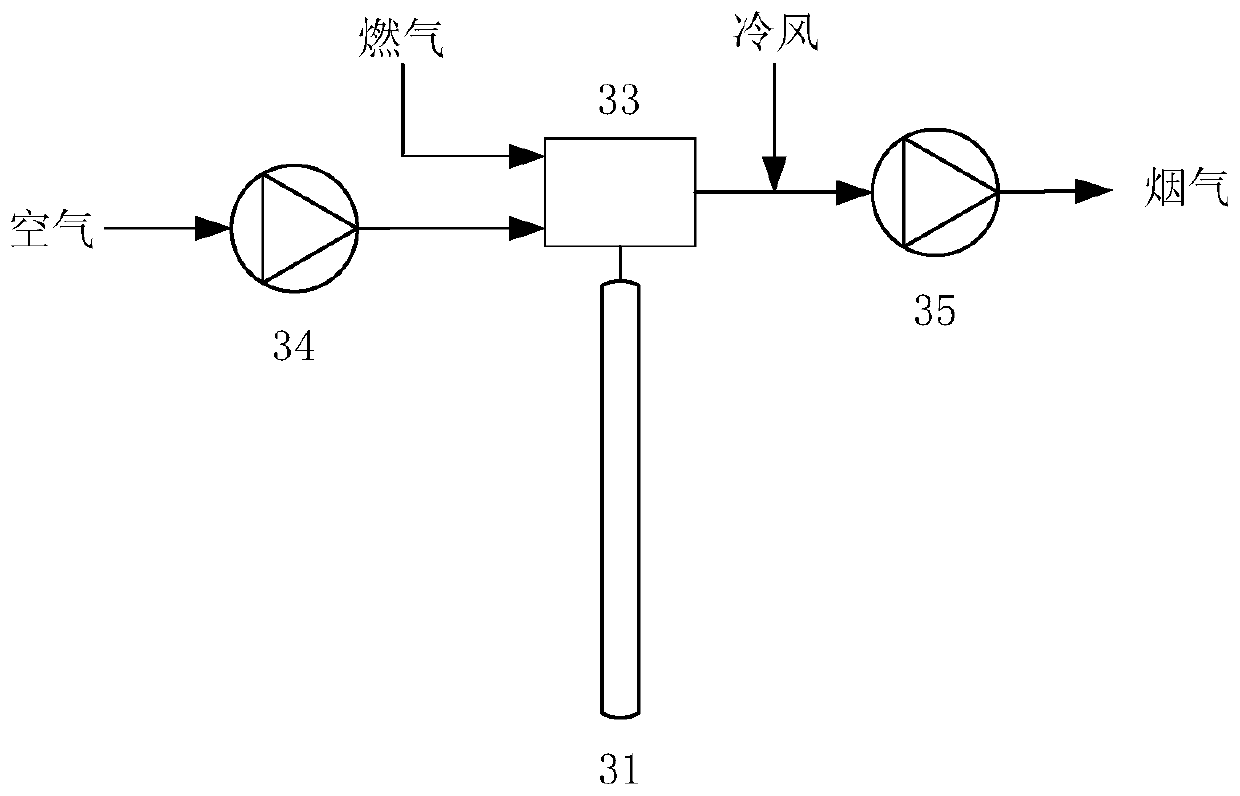

[0031] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention provides a kind of thermal desorption treatment system of organic polluted soil heap, comprising:

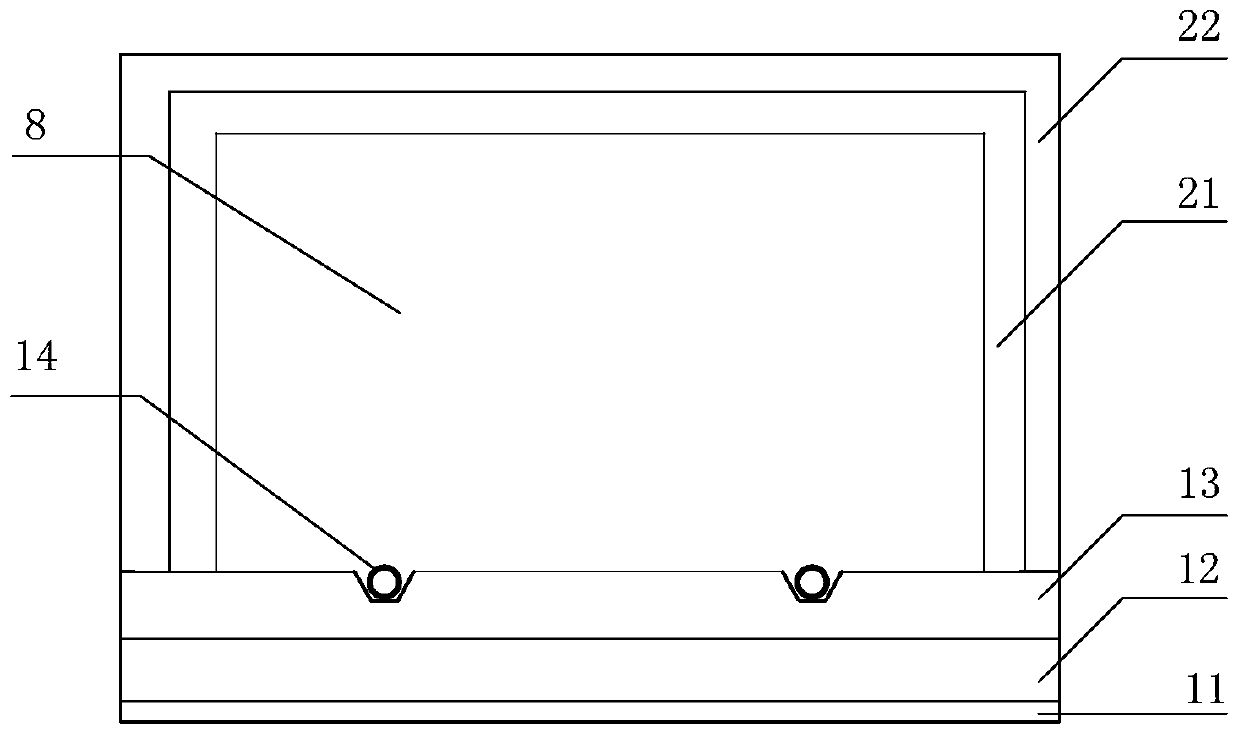

[0032] The ground pollution isolation layer 1 consists of HDPE membrane 11, gravel layer 12, concrete layer 13 and leachate collection pipe 14 from bottom to top. HDPE membrane 11 is first laid on the bottom, and gravel and concrete are laid in sequence on the top as the isolation layer. A leachate collection pipe 14 is provided, and the end of the leachate collection pipe is connected to the tail water t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap