Post-treatment device and method for complex DMF wastewater subjected to DMF recovery

A post-processing device and wastewater recovery technology, which is applied in natural water treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of inability to recycle resources and high energy consumption, and reduce the tower top Condenser, reduced process energy consumption, effect of reduced demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

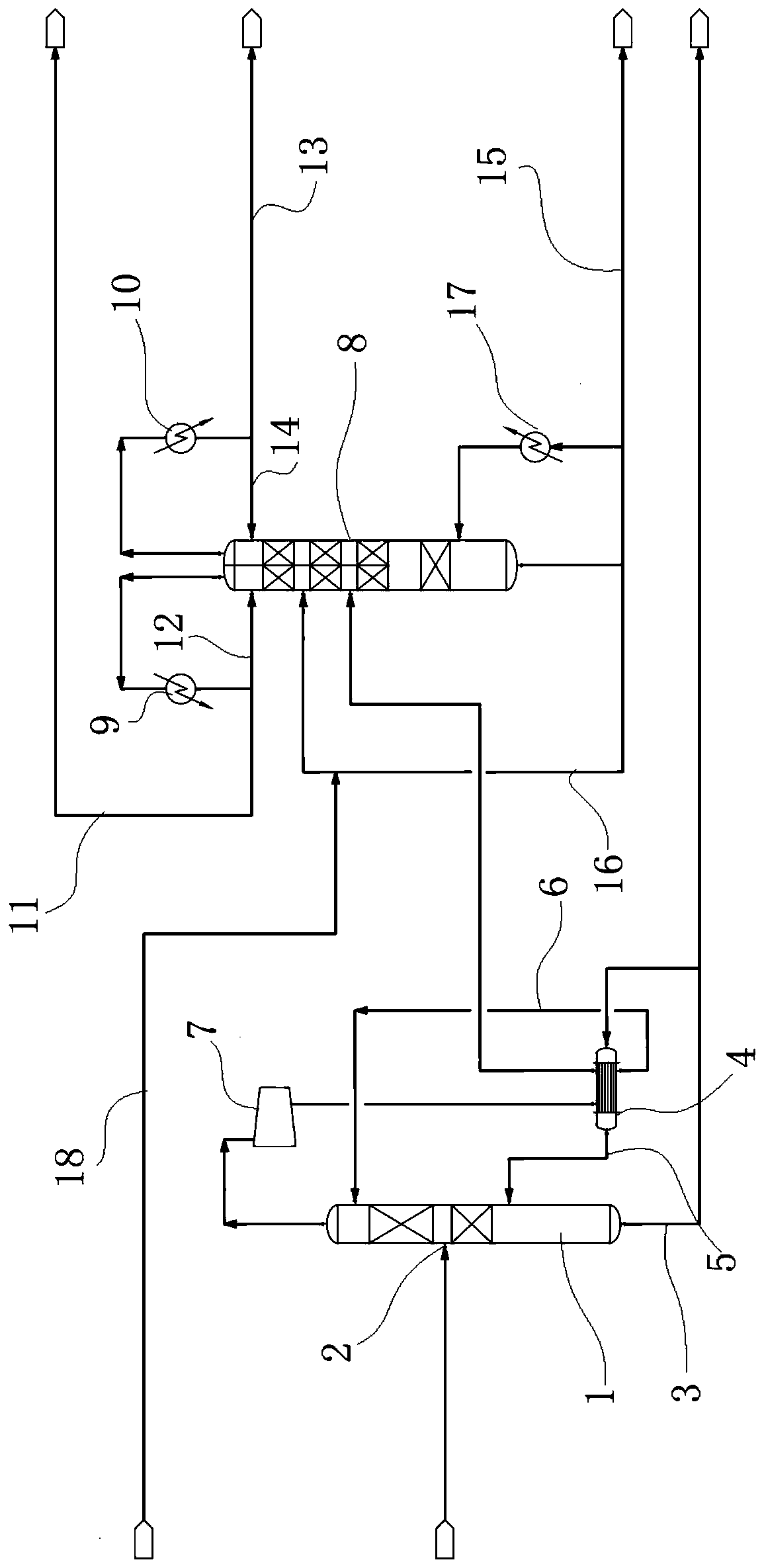

[0042] see figure 1 , a post-treatment device for reclaiming DMF from complex DMF wastewater, used to treat wastewater after reclaiming DMF, including a stripper unit that feeds waste water and a light component treatment unit that is connected to the stripper unit; the stripper unit includes Stripping tower 1, be arranged on the waste water inlet 2 that is communicated with waste water on the stripping tower 1 and be arranged on the stripping tower effluent pipeline 3 at the bottom of the stripping tower 1, be connected on the stripping tower effluent pipeline 3 Stripping tower reboiler 4, this stripping tower reboiler 4 communicates with stripping tower 1 and is provided with the first stripping tower reflux branch 5 and the second stripping tower reflux branch 6, the first stripping tower The reflux branch 5 and the second stripper reflux branch 6 respectively return to the stripper 1, and the top of the stripper 1 is also connected with a light component compressor 7, and ...

specific Embodiment 2

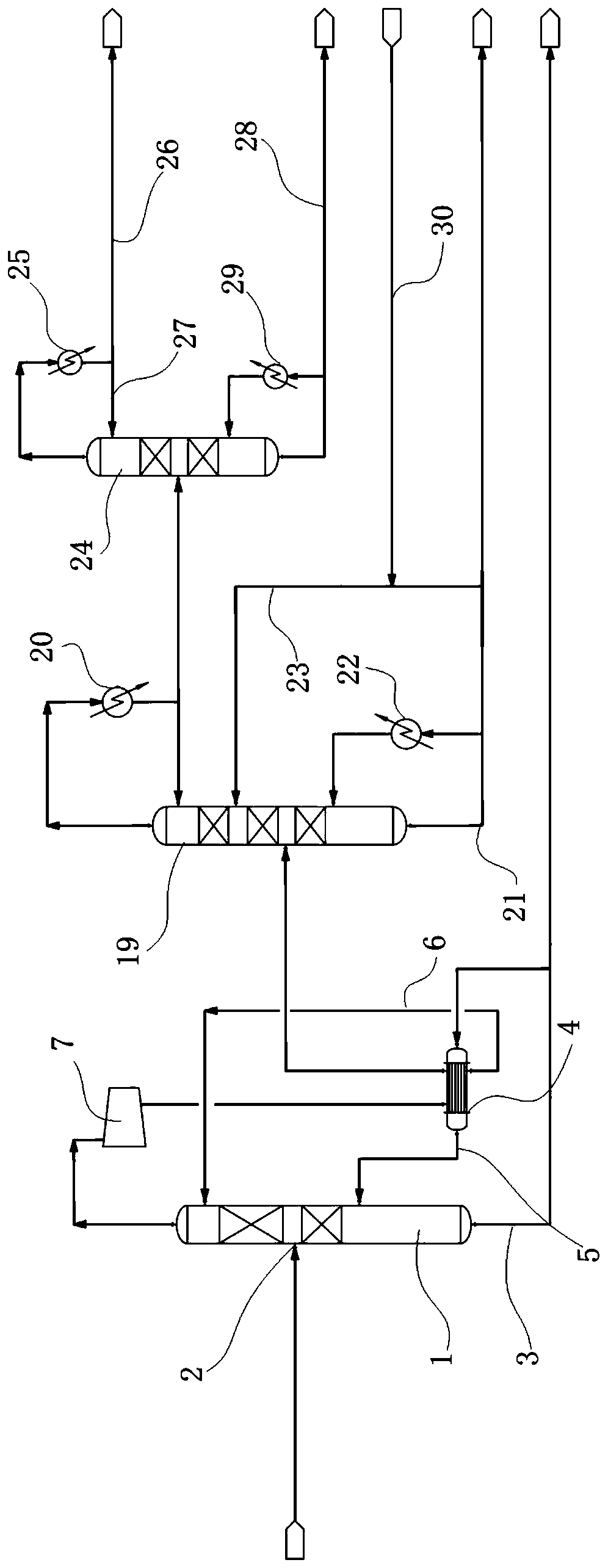

[0065] see figure 2, the difference from specific embodiment 1 is that its light component treatment unit is the light component refining tower 24 that is connected with the ammonia removal tower 19 and the ammonia removal tower 19; the top of the ammonia removal tower 19 is communicated with the ammonia removal tower condenser 20, the amine removal tower condenser 20 is respectively connected to the light component refining tower 24 and refluxed to the amine removal tower 19; The pipeline 21 is respectively communicated with a de-amine tower reboiler 22 and a de-amine tower reflux branch 23, the de-amine tower reboiler 22 is connected to the de-amine tower 19, and the de-amine tower reflux branch 23 is refluxed to the de-amine tower 19 The top of light component refining tower 24 is provided with light component refining tower condenser 25, and this light component refining tower condenser 25 is communicated with first light component refining tower effluent pipeline 26 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com