Shading warping-resistant polyester material for 3D printing and preparation method thereof

A polyester material and 3D printing technology, applied in the field of 3D printing polyester materials, can solve the problems of poor mechanical properties and heat resistance of 3D printing, achieve good anti-warping and shading properties, good compatibility, and improve the use temperature and the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

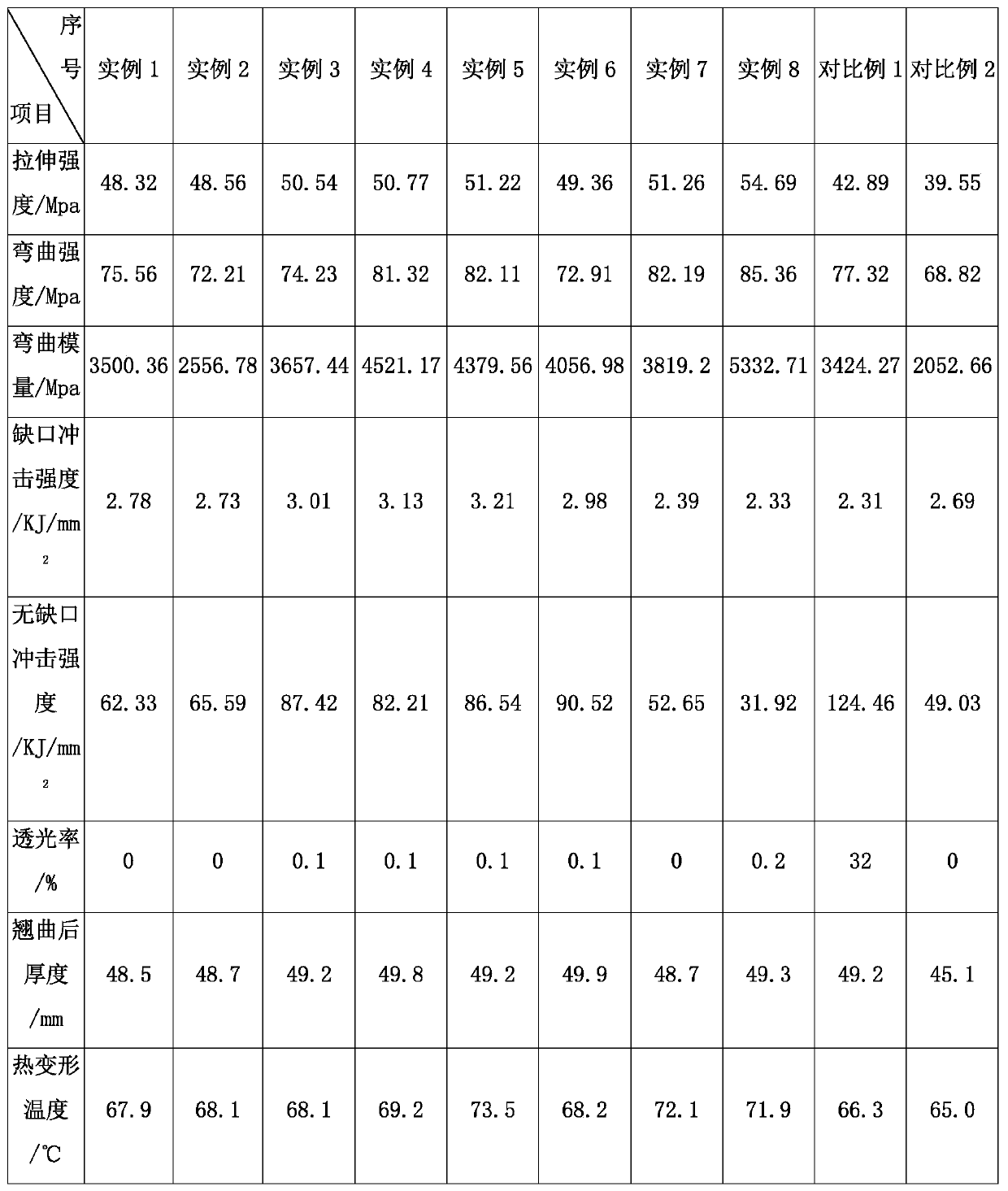

Examples

Embodiment 1

[0028] Put 400 parts of PETG, 100 parts of PCTG, and 20 parts of PCT in a drying oven to dry for 4 hours, so that the moisture content is lower than 0.2%. The drying temperature of PETG and PCTG is 80 ° C, and the drying temperature of PCT is 110 ° C ;Put the dried matrix resin into a high-speed mixer and mix at a low speed for 1-2min at room temperature; add 1 part of diffusing oil and 0.5 part of coupling agent, and mix at a high speed for 5-8min at room temperature; add toughening agent 4 30 parts of montmorillonite, 450 parts of sunscreen, 1 part of main antioxidant, 2 parts of auxiliary antioxidant, 2 parts of lubricant, 0.5 part of anti-UV agent, mix at room temperature for 5-10 minutes, make it fully mixed uniform; the mixed material is added to the twin-screw extruder, and the processing temperature of each zone of the twin-screw extruder is 170-190°C, 220-245°C, 220-245°C, 220-245°C, 220-240°C, 220°C -240°C, 220-240°C, 220-240°C, 220-240°C, 220-240°C, 220-240°C, 230-2...

Embodiment 2

[0030] Put 400 parts of PETG, 100 parts of PCTG, and 40 parts of PCT in a drying oven to dry for 4 hours, so that the moisture content is lower than 0.2%. The drying temperature of PETG and PCTG is 80 ° C, and the drying temperature of PCT is 110 ° C ;Put the dried matrix resin into a high-speed mixer and mix at a low speed for 1-2min at room temperature; add 1 part of diffusing oil and 0.5 part of coupling agent, and mix at a high speed for 5-8min at room temperature; add toughening agent 4 30 parts of montmorillonite, 430 parts of sunscreen, 2 parts of primary antioxidant, 2 parts of auxiliary antioxidant, 2 parts of lubricant, 1 part of anti-UV agent, mix at room temperature for 5-10 minutes, make it fully mixed Uniform; the mixed material is added to the twin-screw extruder, and the processing temperature of each zone of the twin-screw extruder is 170-190°C, 220-245°C, 220-245°C, 220-245°C, 220-240°C, 220°C -240°C, 220-240°C, 220-240°C, 220-240°C, 220-240°C, 220-240°C, 230...

Embodiment 3

[0032]Put 300 parts of PETG, 200 parts of PCTG, and 50 parts of PCT in a drying oven to dry for 4 hours, so that the moisture content is lower than 0.2%. The drying temperature of PETG and PCTG is 80 ° C, and the drying temperature of PCT is 110 ° C ;Put the dried base resin into a high-speed mixer and mix at a low speed for 1-2min at room temperature; add 1 part of diffusing oil and 0.5 part of a coupling agent, and mix at a high speed for 5-8min at room temperature; add toughening agent 6 50 parts of montmorillonite, 400 parts of sunscreen, 1 part of primary antioxidant, 2 parts of auxiliary antioxidant, 2 parts of lubricant, 0.5 part of anti-UV agent, mix at room temperature for 5-10 minutes, make it fully mixed uniform; the mixed material is added to the twin-screw extruder, and the processing temperature of each zone of the twin-screw extruder is 170-190°C, 220-245°C, 220-245°C, 220-245°C, 220-240°C, 220°C -240°C, 220-240°C, 220-240°C, 220-240°C, 220-240°C, 220-240°C, 230...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com