Liquid crystal polymer as well as preparation method and application thereof

A liquid crystal polymer and polyphenylene ether technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of high monomer price, difficult processing, and high product cost, and achieve low melting point, high dielectric constant, and low production cost. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

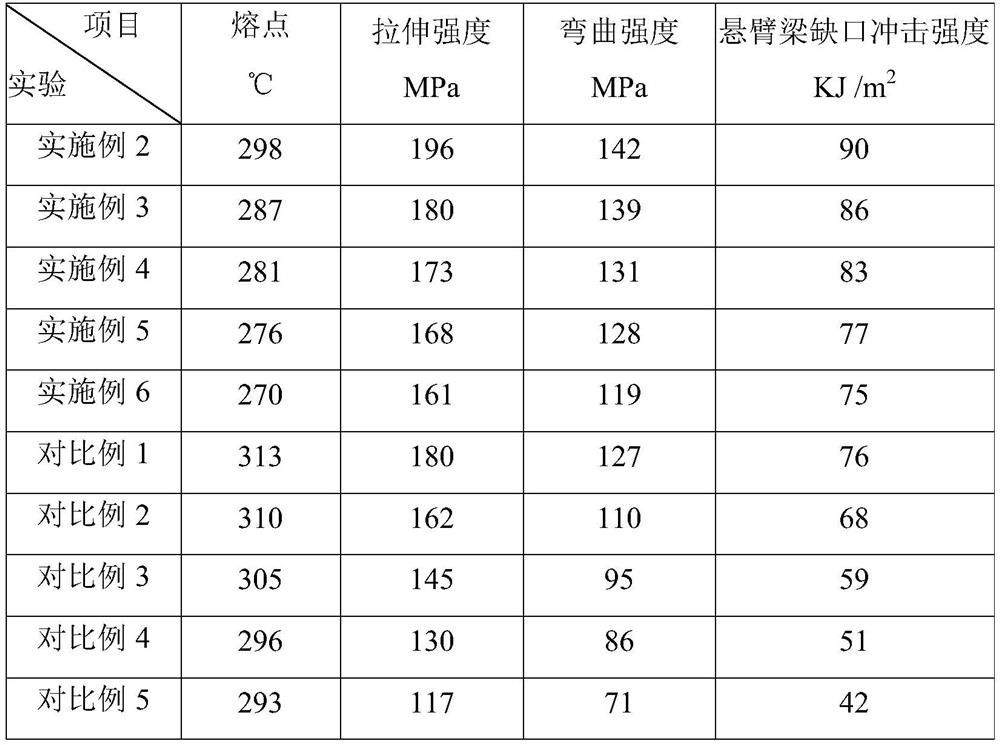

Examples

Embodiment 1

[0047] This example is the preparation of dihydroxy low molecular weight polyphenylene ether.

[0048] Prepare a 5L glass jacketed reactor, equipped with turbine stirring, O 2 The pipeline goes deep from the top of the kettle, the outlet is set under the stirring paddle, and the top of the reactor is set with N 2 Purge lines and condenser.

[0049] Add 2100 g of toluene, 20 g of tetramethylpropylenediamine, 38 g of dimethylbutylamine, and 12 g of cuprous oxide hydrogen bromide solution. Start stirring, feed cooling water into the reactor jacket, control the reaction liquid at 20°C, feed oxygen at 1.4L / min, use a metering pump to mix 2,6-dimethylphenol 700g, tetramethylbisphenol F A solution of 96g and 700g of toluene was continuously and uniformly added to the reactor, the reaction temperature was controlled at 25-30°C, and the reaction time was 80min.

[0050] After the reaction was completed, 200 ml of 2% EDTA-3K solution was added to the reaction solution, the temperatur...

Embodiment 2

[0053] This example is the synthesis of liquid crystal copolymer.

[0054] 2.5L jacketed stirring reactor, the top of the reactor is connected with a separation column, and the separation column is equipped with random packing. Since the acetylation temperature is 120-150°C, and the boiling point of acetic anhydride is 131.6°C, in order to avoid the waste of unreacted acetic anhydride in the acetylation process, measures are taken to control the temperature at the top of the separation column through the reflux flow to not exceed 125°C .

[0055] The low molecular weight bishydroxy polyphenylene ether 35g that obtains in embodiment 1 is dissolved in 50 ℃ 60ml toluene, in N 2 (0.1L / min) under purging, add 517g of acetic anhydride and 0.1mg of zinc acetate, the temperature of the reactor is gradually raised to 145°C, and the reflux temperature at the top of the reactor is controlled at 120°C for 1.0 hour.

[0056] Add 460g HBA, 158g HNA, 5.0g terephthalic acid, continue to mai...

Embodiment 3

[0059] The equipment in Example 2 was used. The low molecular weight bishydroxy polyphenylene ether 60g obtained in embodiment 1 is dissolved in 60 ℃ 90ml toluene; 2 (0.12L / min) under purging, add 500g of acetic anhydride, 0.11g of zinc acetate, gradually heat up the reactor to 145°C, control the reflux temperature at the top of the reactor at 120°C, and keep it for 1 hour; add 438.1g of HBA, 150.5g of HNA , 4.7g of terephthalic acid, continue to maintain 145 ° C for 1 hour, and then increase the temperature to 310 ° C within 2 hours; stop reflux, connect a vacuum pump, and keep the absolute pressure in the reactor at 1KPa for 20 minutes to obtain a liquid crystal polymer.

[0060] In this example, the melting point of the obtained liquid crystal polymer was 287°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com