Preparation method of porous alumina ceramic and preparation method of lithium ion battery diaphragm

A porous alumina, lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problems of poor wettability of electrolyte, easy to fall off, etc., achieve good wetting effect, improve safety performance, and high specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

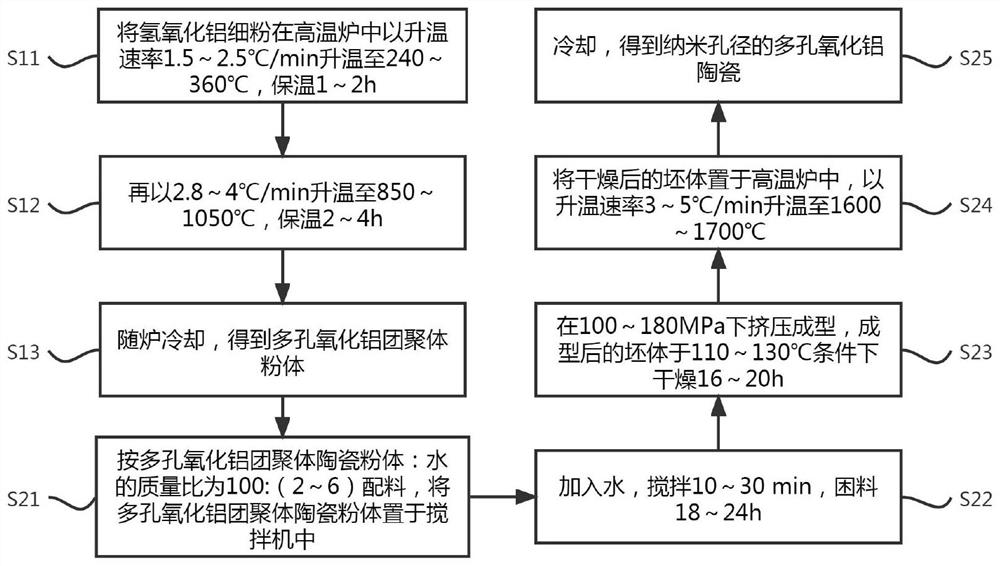

[0030] like figure 1 As shown, this embodiment provides a method for preparing porous alumina ceramics, including the following steps:

[0031] S1. Preparation of porous alumina aggregate ceramic powder:

[0032] S11. Using in-situ decomposition technology to form pores, use aluminum hydroxide fine powder as raw material to heat up to 240-360°C at a heating rate of 1.5-2.5°C / min in a high-temperature furnace, and keep warm for 1-2h;

[0033] S12, then raise the temperature to 850-1050°C at 2.8-4°C / min, and keep warm for 2-4h;

[0034] S13, cooling with the furnace to obtain porous alumina aggregate powder;

[0035] S2. Preparation of porous alumina ceramic powder with nano-pore size:

[0036] S21, according to the mass ratio of porous alumina aggregate ceramic powder: water is 100: (2~6) ingredients, the porous alumina aggregate ceramic powder is placed in the mixer;

[0037] S22. Add water, stir for 10-30 minutes, and wait for 18-24 hours to trap the material;

[0038] S...

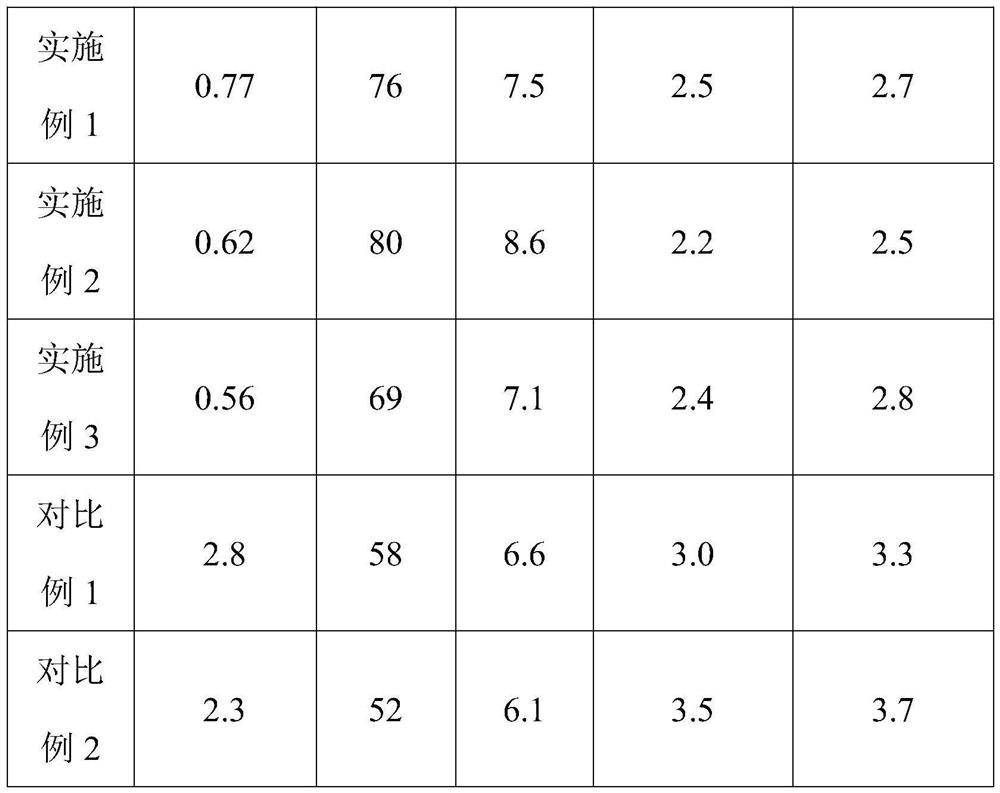

Embodiment 1

[0058] The preparation process of the lithium-ion battery separator of the present embodiment is as follows:

[0059] (1) Preparation of porous alumina aggregate ceramic powder

[0060] Using the in-situ decomposing pore-forming technology, aluminum hydroxide fine powder was used as raw material in a high-temperature furnace to raise the temperature to 240°C at a heating rate of 1.5°C / min, hold for 1h, then raise the temperature to 850°C at 2.7°C / min, hold for 2h, and then The furnace is cooled to obtain porous alumina aggregate powder.

[0061] (2) Preparation of porous alumina ceramic powder with nanopore size

[0062] 1. According to the mass ratio of porous alumina aggregate ceramic powder: water as 100:2, put the porous alumina aggregate ceramic powder in the mixer, then add water, stir for 10min, and after 18h of stuffing, the mixture is heated at 100MPa Under extrusion molding, the formed green body is dried at 110°C for 16 hours, then the dried green body is placed i...

Embodiment 2

[0070] The preparation process of the lithium-ion battery separator of the present embodiment is as follows:

[0071] (1) Preparation of porous alumina aggregate ceramic powder

[0072] Using the in-situ decomposition technology, aluminum hydroxide fine powder is used as raw material to heat up to 300°C at a heating rate of 2°C / min in a high-temperature furnace, hold for 1.5h, then raise the temperature to 950°C at 3.4°C / min, and hold for 3h. After cooling in the furnace, the porous alumina aggregate powder is obtained.

[0073] (2) Preparation of porous alumina ceramic powder with nanopore size

[0074] 1. The mass ratio of porous alumina aggregate ceramic powder: water is 100:4, and the porous alumina aggregate ceramic powder is placed in a mixer, then the water is added, stirred for 20 minutes, and the material is trapped for 21 hours. Extruded at 140MPa, the formed green body was dried at 120°C for 18 hours, then the dried green body was placed in a high-temperature furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com