Secondary copper sulfide treatment method

A technology of copper sulfide ore and processing method, which is applied in the directions of photography technology, instruments, photography auxiliary technology, etc. Influence and other problems, to achieve the effect of increasing the leaching rate, increasing the copper leaching rate, and improving the operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below.

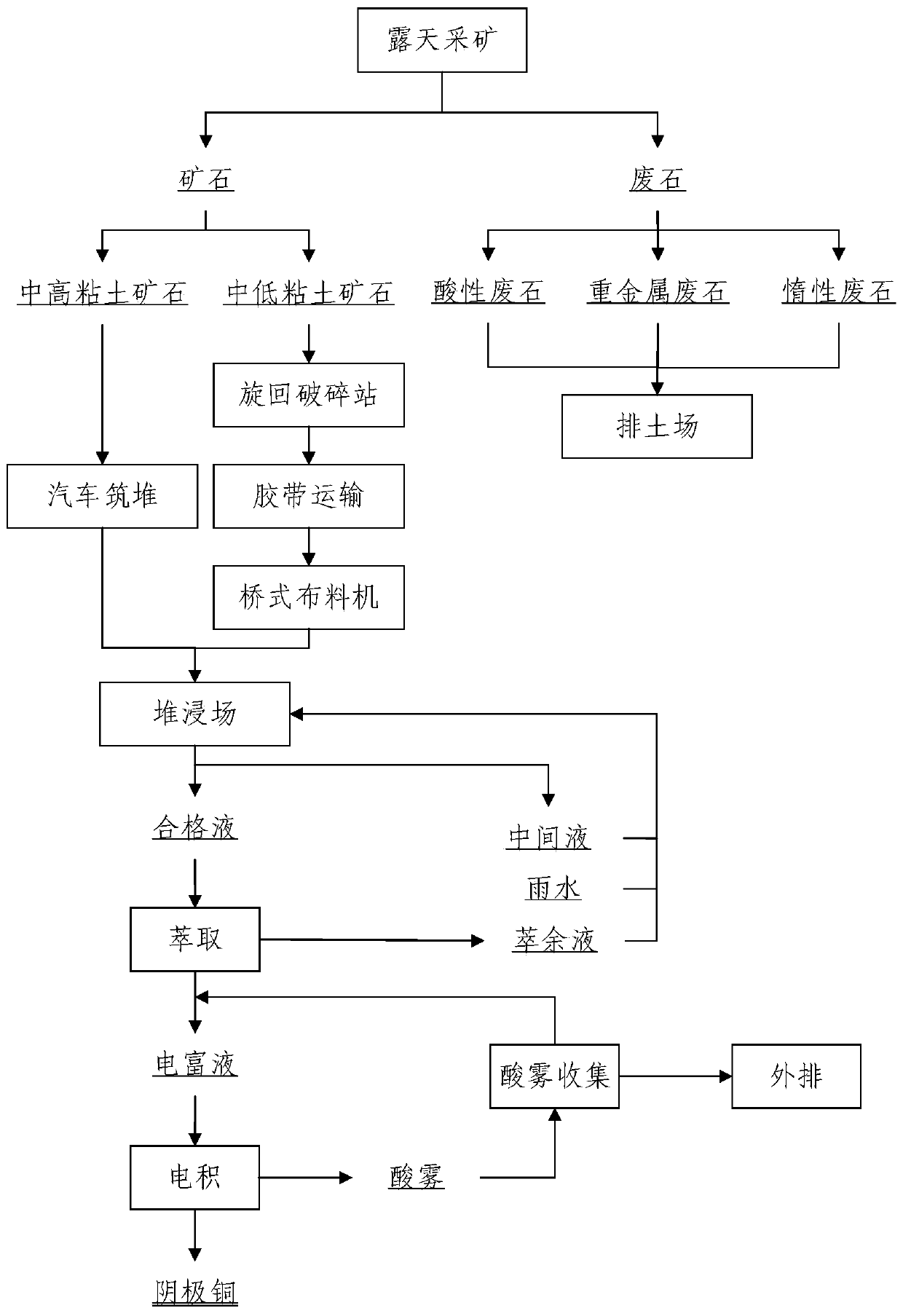

[0021] A kind of secondary copper sulfide ore processing method that the present invention proposes specifically comprises the following steps:

[0022] S1. Determine the nature of the waste rock in the mine and discharge the soil at the designated location: according to the chemical analysis results of the waste rock, it is divided into three categories, namely acid waste rock, heavy metal waste rock and inert waste rock. The waste rocks are directly transported by mining trucks. The acid waste rocks are discharged on the innermost side of each layer of the dump, the outside of the acid waste rocks are heavy metal waste rocks, and the outside of the heavy metal waste rocks are inert waste rocks. The dumping space occupied by the three types of waste rocks varies, and is strictly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com