A process for producing high-quality sodium silicate using high-silicon iron ore

A sodium silicate and sodium silicate solution technology, which is applied in the direction of silicate, alkali metal silicate, process efficiency improvement, etc., can solve the problem of high energy consumption per ton of iron, no energy saving and environmental protection advantages, failure of iron recovery, etc. problems, to save energy, speed up the leaching rate, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] According to an embodiment of the present invention, a kind of technique that adopts ferrosilicon ore to produce high-quality sodium silicate is provided:

[0106] A kind of technique that adopts high-silicon iron ore to produce high-quality sodium silicate comprises the following steps:

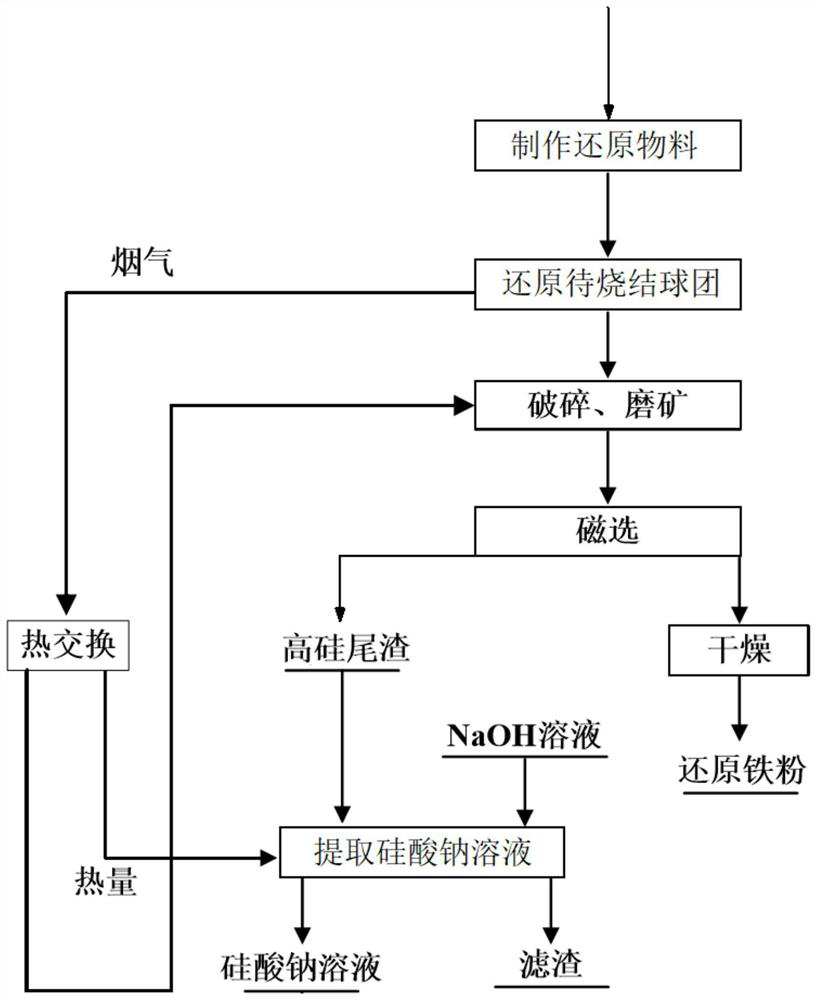

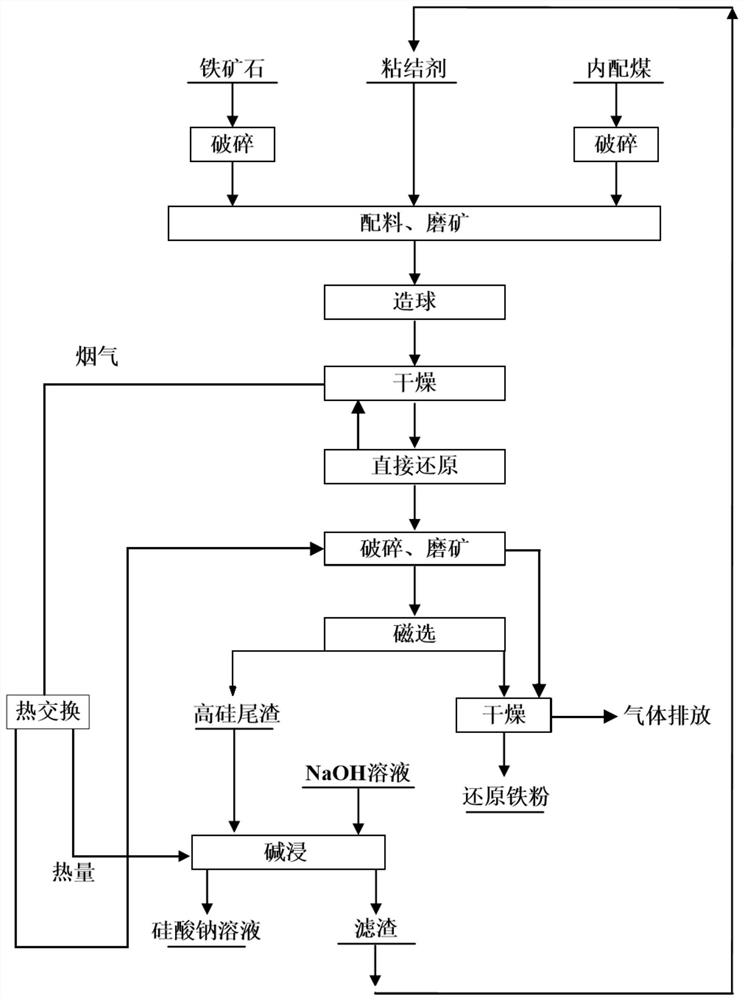

[0107] 1) Making reduced materials: making high-silicon iron ore into pellets to be sintered.

[0108] 2) Reducing the pellets to be sintered: heating the pellets to be sintered at high temperature to obtain reduced pellets.

[0109] 3) High-silicon tailings are selected by crushing and milling: crushing and reducing pellets to obtain reduced scraps, using an ultra-fine milling device to grind and select the reduced scraps to obtain reduced powders, and magnetically separating the reduced powders to obtain high-silicon tailings.

[0110] 4) Extraction of sodium silicate solution: adding lye to the high-silicon tailings to obtain a solid-liquid mixture, and leaching the sodium silicat...

Embodiment 2

[0112] Repeat embodiment 1, only step 3) in the discharge granularity of superfine grinding device is 800 orders.

Embodiment 3

[0114] Repeat Example 2, except that the temperature of low-temperature heating in step 2) is 950°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com