Method for leaching valuable metals from batteries using nanobubbles

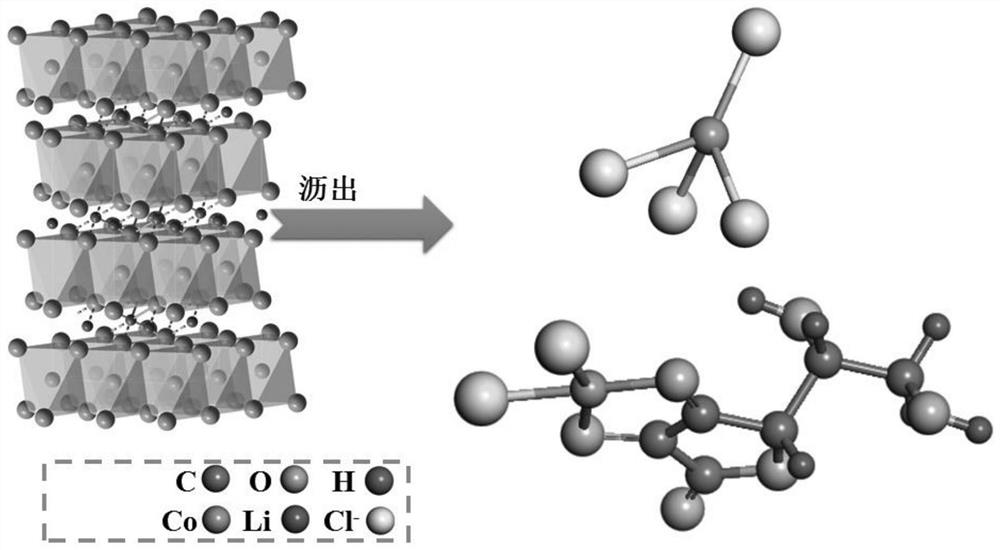

A nano-bubble and valuable metal technology, used in battery recycling, recycling technology, and process efficiency improvement, can solve problems such as slow reaction rates, improve leaching efficiency, reduce acid usage, and leaching effects. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

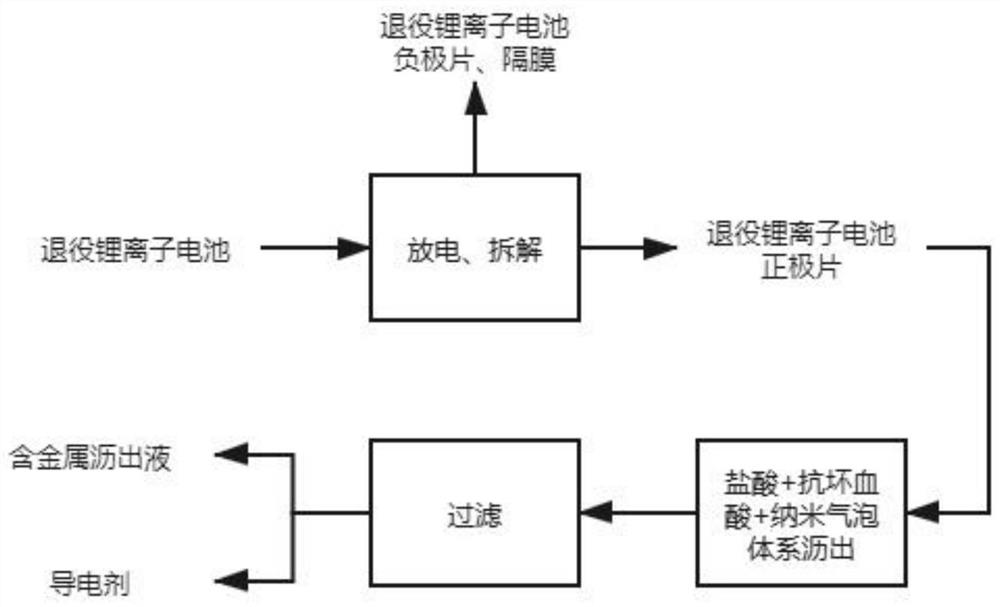

[0094] A method for leaching valuable metals from batteries using nanobubbles, achieved through the following steps:

[0095] (1) Simple preprocessing:

[0096] Fully discharge the decommissioned lithium-ion battery, manually disassemble and remove the shell in the glove box, separate the diaphragm and negative electrode, and take out the positive electrode sheet (that is, the positive electrode material); dry the positive electrode sheet to make the organic solvent such as the electrolyte volatilize, this process does not require complicated procedures Pretreatment process before leaching.

[0097] (2) Preparation of nanobubbles:

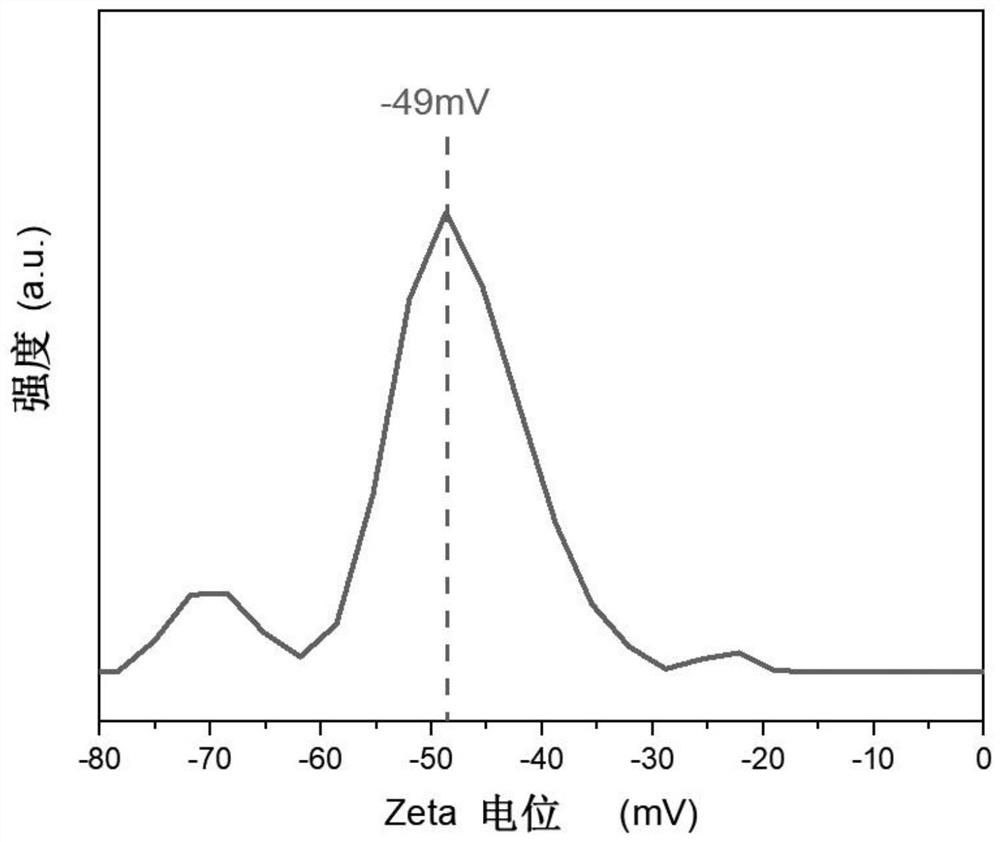

[0098] Pour deionized water into the mechanical stirring equipment, and pass through oxygen for 5 minutes to exhaust the air in the equipment. Close the air outlet, turn on the stirring, and set the blade to rotate rapidly for 10 minutes. After stirring, the aqueous solution containing oxygen nanobubbles (the zeta potential is about -70mV) is po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com