Calibration method of a cross type hot wire anemometer

A hot-wire anemometer and calibration method technology, applied in the testing/calibration of velocity/acceleration/shock measuring equipment, instruments, velocity/acceleration/shock measurement, etc. problem, to achieve the effect of reducing the number of calibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

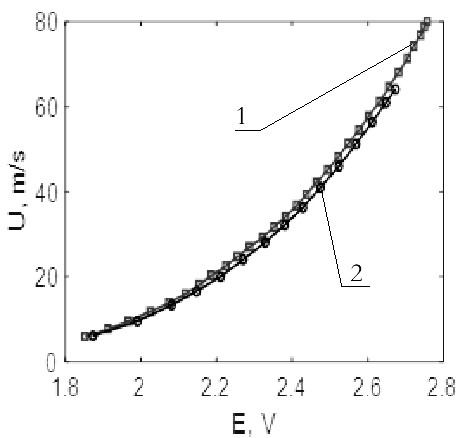

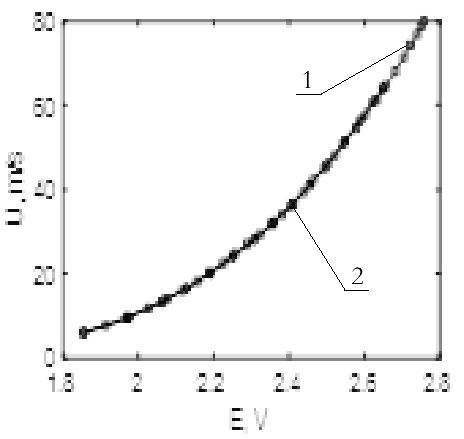

[0045] Under standard atmospheric pressure conditions, two calibration data sets were measured when the average ambient temperature was 21°C and 25°C respectively. Among them, when the ambient temperature is 25°C, there are 11 tilt angles (from -30° to 30°, with a step size of 6°) and 30 flow velocity values (from 5m / s to 80m / s) at each angle measuring point. ; When the ambient temperature is 21°C, there are 11 tilt angles and 15 flow velocity values at each angle measuring point.

[0046] The calibration method of the cross type hot wire anemometer comprises the following steps:

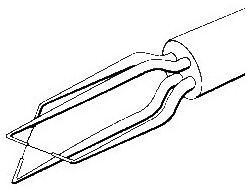

[0047] Step 1: Install the cross-type hot wire probe on the adjustable calibrator, and measure the angle θ between the cross-type hot wire probe and the airflow direction;

[0048] Step 2: Use a multimeter to measure the resistance value of the hot wire, probe bracket, and connecting cable, set the superheat ratio of the normal temperature anemometer according to the resistance value, and use t...

Embodiment 2

[0057] In the HRTF high Reynolds number (maximum pressure 238atm) recirculation wind tunnel,.

[0058] The calibration method of the cross type hot wire anemometer comprises the following steps:

[0059] Step 1: Install the cross-type hot wire probe on the adjustable calibrator, and measure the angle θ between the cross-type hot wire probe and the airflow direction;

[0060] Step 2: Use a multimeter to measure the resistance value of the hot wire, probe bracket, and connecting cable, set the superheat ratio of the normal temperature anemometer according to the resistance value, and use the data card to convert the analog output of the normal temperature anemometer into a numerical value;

[0061] Step 3: Set the sampling rate and acquisition time, turn on the calibrator and the normal temperature anemometer, and start data collection; record physical quantities: the voltage output E of the normal temperature anemometer, the wind speed value U of the calibrator ∞ And air tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com