Chemically resistant fluorinated multiblock polymer structures, methods of manufacturing and use

A technology of fluorinated polymers and polymers, applied in chemical instruments and methods, membranes, membrane technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

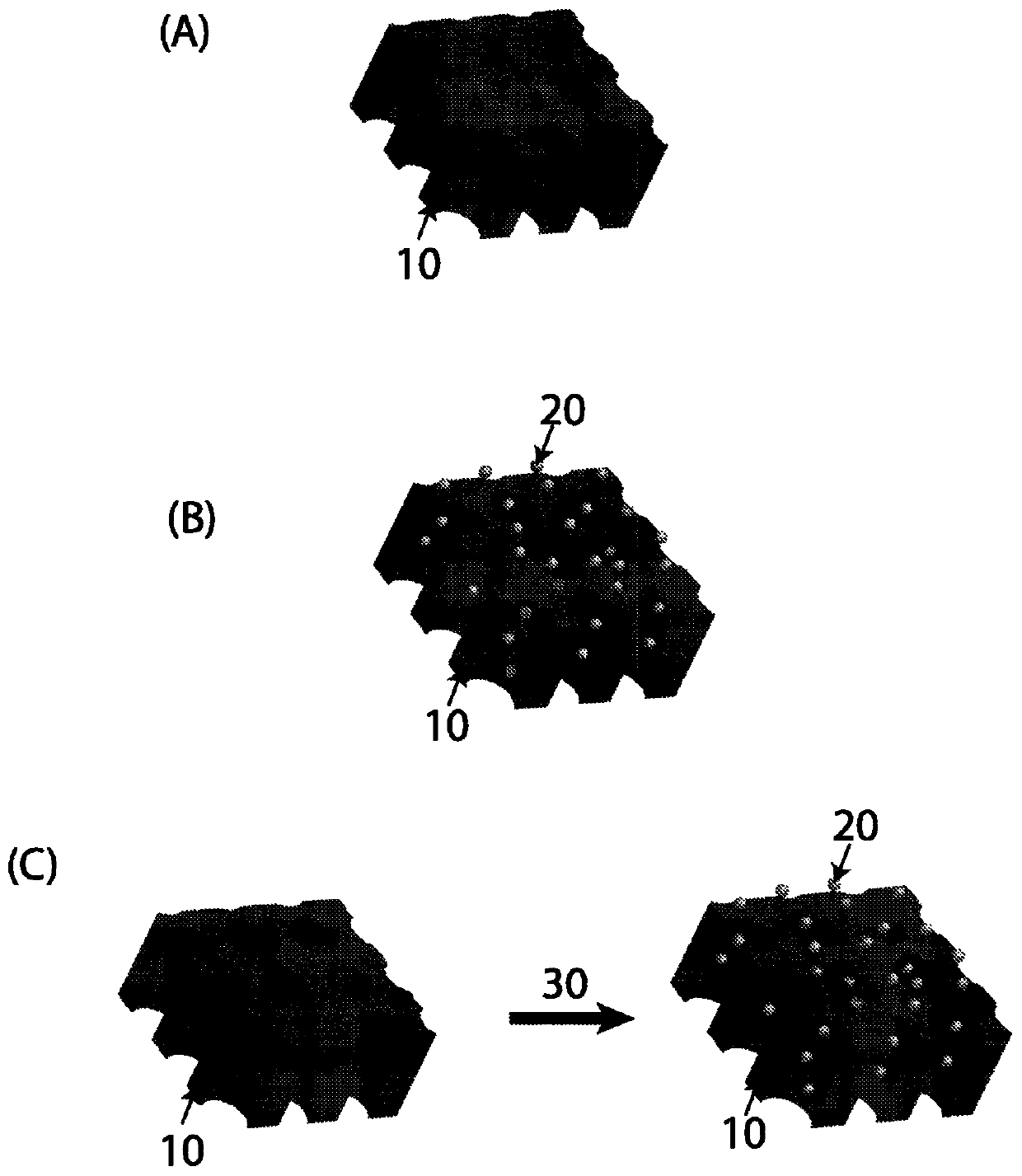

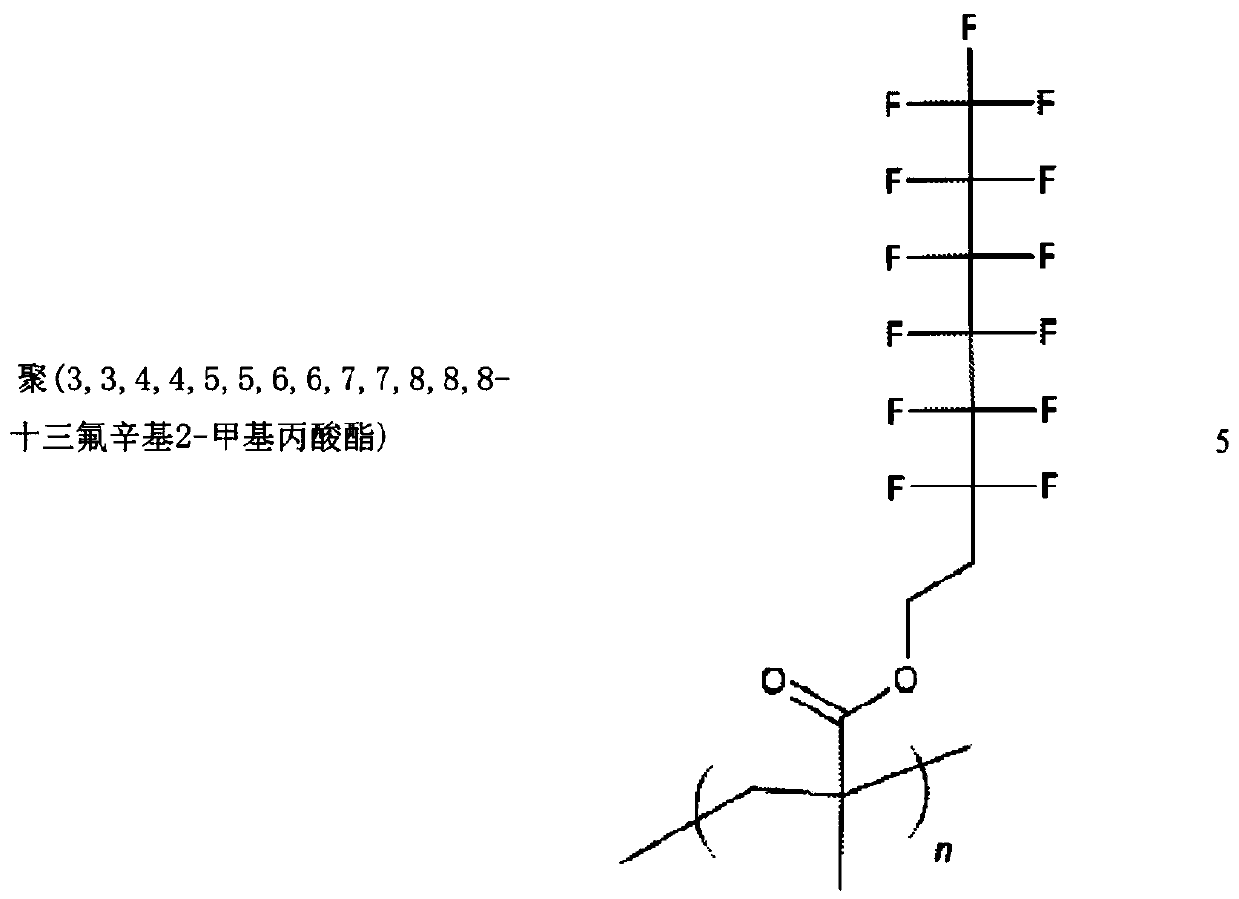

[0026] The present invention is a homoporous structure comprising at least one multi-block polymer, wherein at least one block comprises at least one moiety containing fluorine atoms ("fluorinated"), e.g. membranes, films, fabrics , Monolith. The incorporation of fluorine atoms imparts chemical resistance and antifouling properties to the homoporous block copolymer structure. This combination of fluorinated polymer blocks (e.g., A-B, A-B-C, A-B-C-D, or A-B-C-D-E) in a multi-block copolymer structure generated by self-assembly results in separations in non-aqueous liquid media such as organic or harsh liquid media. High permeability and high selectivity homoporous structure. In addition, fluorination adds an anti-fouling effect to the material.

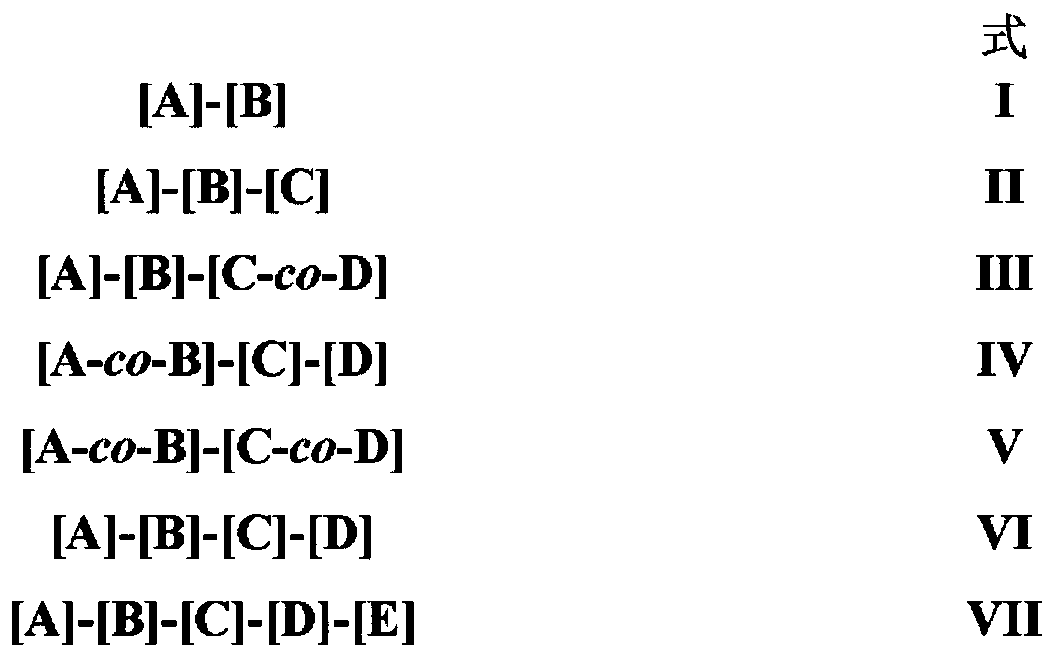

[0027] Table 1 below provides non-limiting examples of block copolymer configurations. Different letters indicate different chemical compositions, where A, B, C, D, and E are each polymer blocks formed from the same monomer, and -co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com