Preparation method of sulfur-doped nickel, iron, cobalt ternary hydroxide high-performance oxygen evolution catalyst with stepped three-dimensional structure

A three-dimensional structure and hydroxide technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems that have not been reported before, and achieve good process repeatability, cheap and easy-to-obtain raw materials, The effect of high oxygen evolution reaction activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

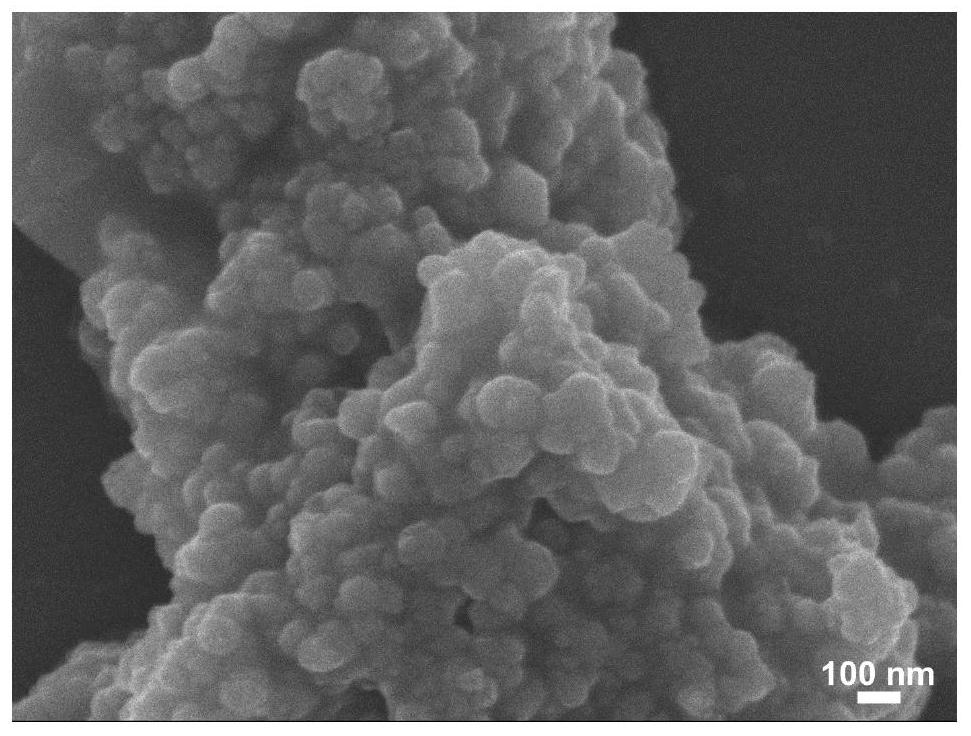

[0014] Take by weighing 5.463g nickel nitrate (H 12 N 2 NiO 12 ) and 2.517g ferric nitrate (H 18 FeN 3 o 18 ) and 0.604g cobalt nitrate (CoH 12 N 2 o 12 ) was dissolved in 30mL deionized water, 2.304g sodium hydroxide (NaOH) and 2.544g sodium carbonate (NaOH) 2 CO 3 ) was dissolved in 30 mL of deionized water, and then the two solutions were mixed vigorously and stirred at 80 ° C for 48 h, and the obtained precipitate was centrifuged and dried at 60 ° C for 24 h to obtain the desired precursor. 80mg precursor and 0.1125g thioacetamide (CH 3 CSNH 2 ) was dissolved in 40mL of ethanol, solvothermally reacted at 120°C for 6h, centrifuged the obtained precipitate, and dried at 60°C for 24h to obtain a sulfur-doped nickel, iron, cobalt ternary hydroxide with a ladder stereostructure with high performance Oxygen evolution catalyst, electrochemical test results show that its current density reaches 10mA cm -2 , the overpotential is only 200mV, and the Tafel slope is as sma...

Embodiment 2

[0016] Take by weighing 5.463g nickel nitrate (H 12 N 2 NiO 12 ) and 2.517g ferric nitrate (H 18 FeN 3 o 18 ) and 0.604g cobalt nitrate (CoH 12 N 2 o 12 ) was dissolved in 30mL deionized water, 2.304g sodium hydroxide (NaOH) and 2.544g sodium carbonate (NaOH) 2 CO 3 ) was dissolved in 30 mL of deionized water, and then the two solutions were mixed vigorously and stirred at 80 ° C for 48 h, and the obtained precipitate was centrifuged and dried at 60 ° C for 24 h to obtain the desired precursor. 80mg precursor and 0.1125g thioacetamide (CH 3 CSNH 2 ) was dissolved in 40mL ethanol, solvothermally reacted at 100°C for 6h, centrifuged the obtained precipitate, and dried at 60°C for 24h to obtain a sulfur-doped nickel, iron, cobalt ternary hydroxide with a ladder stereostructure with high performance Oxygen evolution catalyst, electrochemical test results show that its current density reaches 10mA cm -2 , the overpotential is only 200mV, and the Tafel slope is as small ...

Embodiment 3

[0018] Take by weighing 5.463g nickel nitrate (H 12 N 2 NiO 12 ) and 2.517g ferric nitrate (H 18 FeN 3 o 18 ) and 0.604g cobalt nitrate (CoH 12 N 2 o 12 ) was dissolved in 30mL deionized water, 2.304g sodium hydroxide (NaOH) and 2.544g sodium carbonate (NaOH) 2 CO 3 ) was dissolved in 30 mL of deionized water, and then the two solutions were mixed vigorously and stirred at 80 ° C for 48 h, and the obtained precipitate was centrifuged and dried at 60 ° C for 24 h to obtain the desired precursor. 80mg precursor and 0.1125g thioacetamide (CH 3 CSNH 2 ) was dissolved in 40mL of ethanol, solvothermally reacted at 140°C for 6h, centrifuged the obtained precipitate, and dried at 60°C for 24h to obtain a sulfur-doped nickel, iron, cobalt ternary hydroxide with a ladder stereostructure with high performance Oxygen evolution catalyst, electrochemical test results show that its current density reaches 10mA cm -2 , the overpotential is only 200mV, and the Tafel slope is as sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com