Platinum phosphide nano-catalyst, preparation method thereof and application of platinum phosphide nano-catalyst in electrocatalytic oxygen reduction

A platinum catalyst and catalyst technology, applied in the field of nanoscience, can solve the problems of lack of versatility, high process cost, unfavorable large-scale production, etc., and achieve the effects of avoiding the use of transition metals, large application potential, and excellent catalytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of platinum phosphide nano-catalyst comprises the following steps:

[0039] Step 1, dispersing the platinum catalyst in a solvent to obtain a platinum catalyst dispersion;

[0040] Step 2, adding a phosphorus source to the platinum catalyst dispersion in step 1, stirring evenly, heating and reacting, centrifuging and washing after the reaction to obtain a platinum phosphide nano-catalyst.

[0041]In step 1, the platinum catalyst is platinum nanocrystal, platinum-based alloy or supported platinum-based catalyst. Platinum-based alloys are platinum-based binary alloys such as platinum-cobalt, platinum-nickel, platinum-iron, platinum-copper, platinum, and platinum-palladium, platinum-based ternary alloys such as platinum-cobalt-nickel, platinum-rhodium-palladium, and platinum-iron-manganese, and platinum-based multiple alloys Wait. Supported platinum-based catalysts are commercial platinum / carbon, platinum / alumina, platinum / silica, platinum / titania ...

Embodiment 1

[0047] The preparation method of platinum phosphide nano-catalyst of the present invention comprises the following steps:

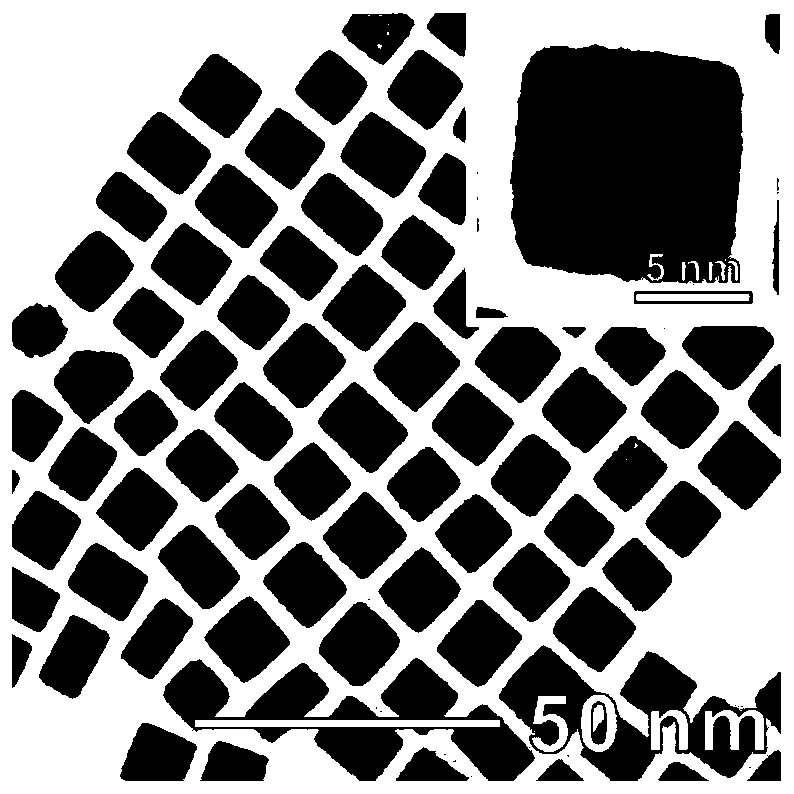

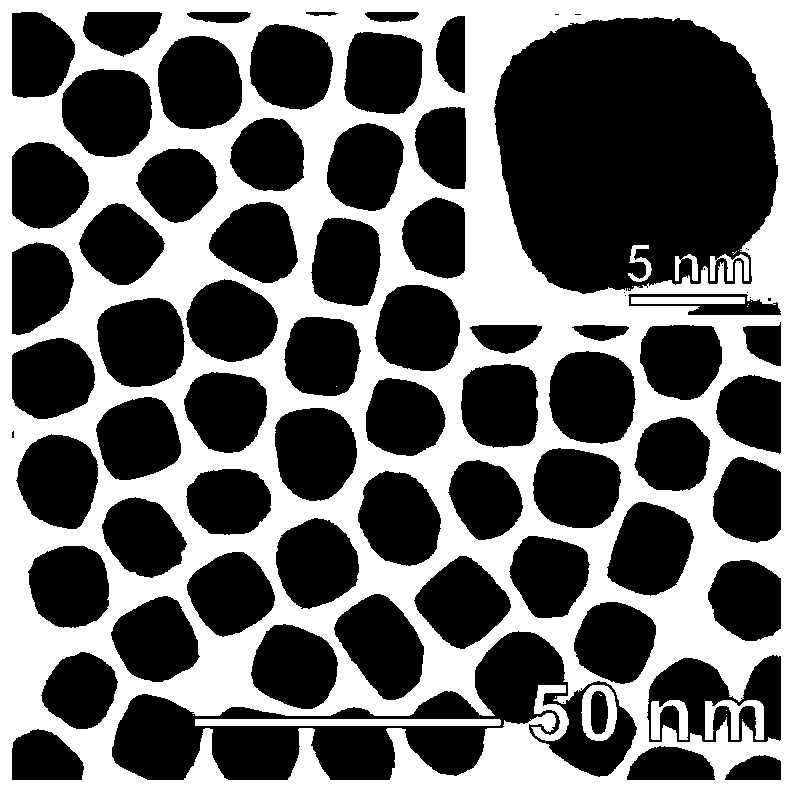

[0048] 1) Ultrasonic dispersion of 3.76 mg of platinum nanocubes (average particle size of 8 nm) in 10 mL of oleylamine to obtain a stable platinum catalyst dispersion, wherein the concentration of platinum is 0.376 mg / mL;

[0049] 2) Add 1.6 mL of tri-n-octylphosphine to the platinum catalyst dispersion in step 1), and stir evenly to obtain a reaction precursor;

[0050] 3) Heating and stirring the reaction precursor solution at 300° C., centrifuging and washing after reacting for 1 hour to obtain a platinum phosphide nano-catalyst. The content of phosphorus atoms in the catalyst is 4%, the morphology remains as nano-cubes, and the size does not change significantly.

Embodiment 2

[0052] The preparation method of platinum phosphide nano-catalyst of the present invention comprises the following steps:

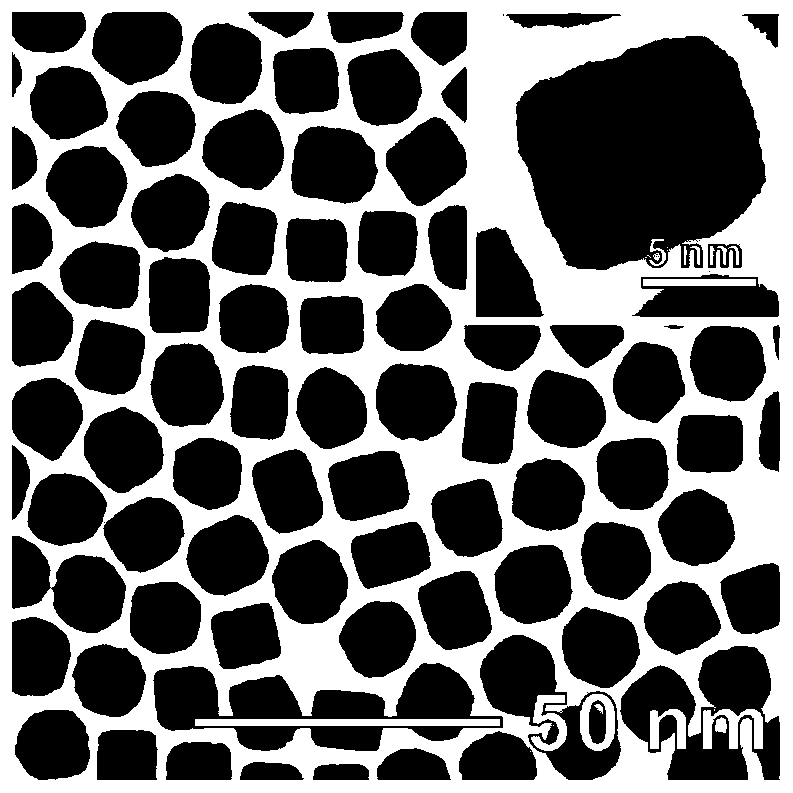

[0053] 1) Ultrasonic dispersion of 3.76 mg of platinum nanocubes (average particle size of 8 nm) in 10 mL of oleylamine to obtain a stable platinum catalyst dispersion, wherein the concentration of platinum is 0.376 mg / mL;

[0054] 2) Add 1.6 mL of tri-n-octylphosphine to the platinum catalyst dispersion in step 1), and stir evenly to obtain a reaction precursor;

[0055] 3) heating and stirring the reaction precursor solution at 300° C., centrifuging and washing after reacting for 1.5 hours to obtain a platinum phosphide nano-catalyst. The content of phosphorus atoms in the catalyst is 10%, and the shape gradually changes to a cube with cut corners.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com