Halogen-containing flame-retardant TPE material and preparation method thereof

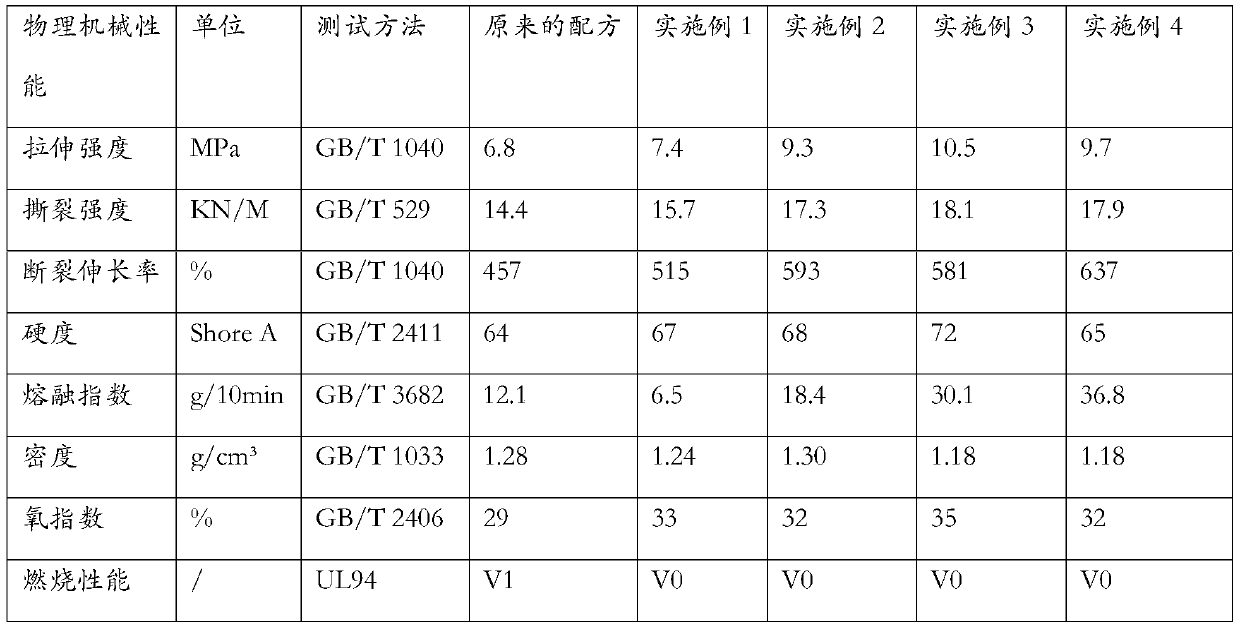

A raw material, styrene technology, applied in the field of halogenated flame-retardant TPE materials and its preparation, can solve the problems of low tensile strength, poor performance, general compatibility between flame retardants and resin matrix, etc., to achieve high tensile strength, Effects of excellent properties, electrical insulation properties and improved blendability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the above-mentioned halogenated flame-retardant TPE material comprises the following steps:

[0041] 1) Mix the non-oil-extended styrene-ethylene-butylene-styrene block copolymer SEBS and mineral oil at a ratio of 1:0.5-2 to obtain oil-extended styrene-ethylene-butylene =Styrene block copolymer styrene-ethylene-butylene-styrene block copolymer SEBS, the mixer speed is 1000 rpm, and the mixing time is 3 minutes;

[0042] 2) Disperse and premix the oil-extended styrene-ethylene-butylene-styrene block copolymer SEBS, chlorinated polyethylene, polypropylene, antioxidant, and lubricant in a high-speed mixer to obtain premix B , the speed of the mixer is 800 rpm, and the mixing time is 3 minutes;

[0043] 3) Disperse and mix decabromodiphenylethane, antimony trioxide, talcum powder, and mixture B through a high-speed mixer to obtain premix C. The speed of the mixer is 100 rpm, and the mixing time is 5 minutes;

[0044] 4) Premix C is melted, kneade...

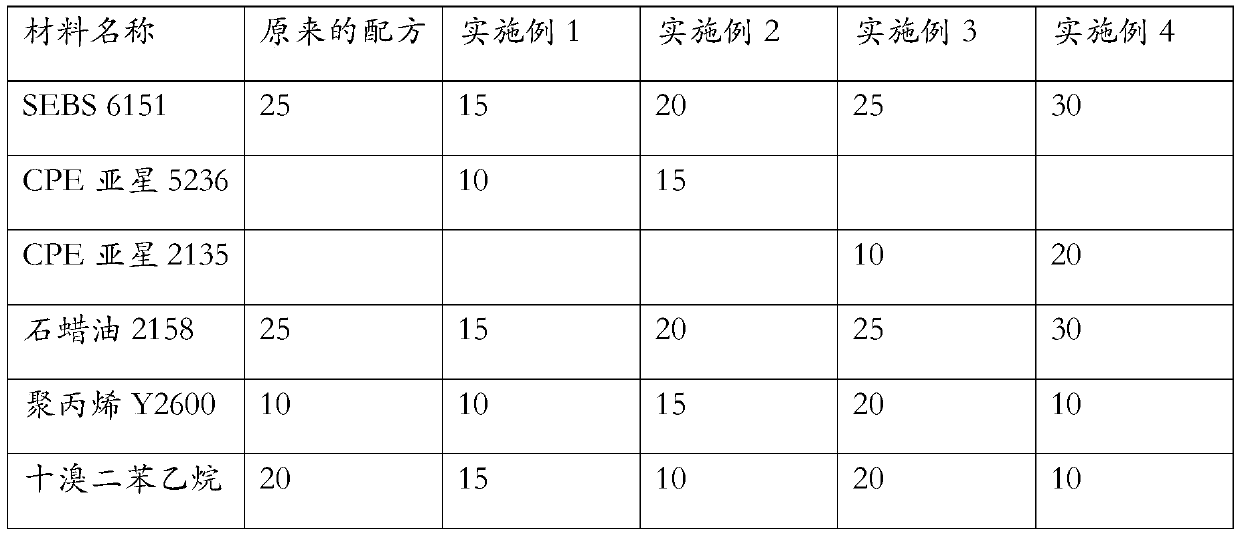

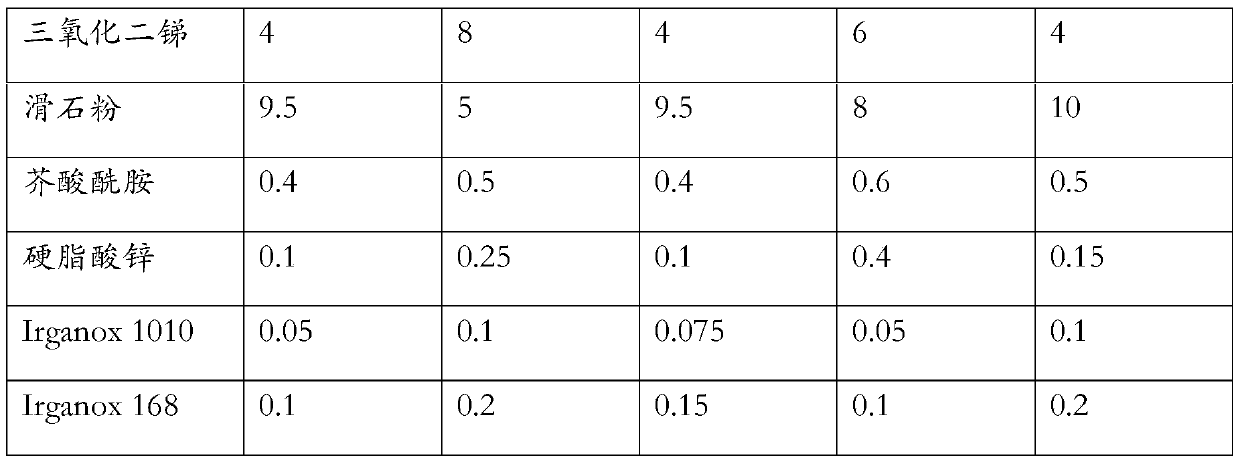

Embodiment 1

[0047] In this embodiment, SEBS is selected from Taiwan Rubber 6151, 15 parts; chlorinated polyethylene CPE Yaxing 5236, 10 parts; paraffin oil is selected from German Hansheng 2158, 15 parts; polypropylene Y2600, 10 parts; decabromodiphenylethane , 15 parts; antimony trioxide, 8 parts; talcum powder, 5 parts; lubricants are zinc stearate and erucamide, wherein, zinc stearate 0.5, erucamide 0.25; antioxidants are Irganox1010 and Irganox168 , the addition ratio of the two is 1:2, 0.1 part for Irganox1010, and 0.2 part for Irganox168.

Embodiment 2

[0049] In this embodiment, SEBS selects Taiwan Rubber 6151, 20 parts; Chlorinated polyethylene CPE Yaxing 5236, 15 parts; Paraffin oil selects German Hansheng 2158, 20 parts; Polypropylene Y2600, 15 parts; Decabromodiphenylethane , 10 parts; Antimony trioxide, 4 parts; Talcum powder, 9.5 parts; Lubricant selects zinc stearate and erucamide for use, wherein, zinc stearate 0.4 part, erucamide 0.1 part; Antioxidant is Irganox1010 and Irganox168, the addition ratio of the two is 1:2, Irganox1010 is 0.075 parts, and Irganox168 is 0.15 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com