Method of increasing oil yield and in-situ flocculation harvesting efficiency of microalgae growing in sewage

A technology of microalgae oil and in-situ flocculation, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of low oil content of growing microalgae, low recovery rate of microalgae, etc., and achieve the reduction of organic acid content, improve the water environment, and realize the effect of resource treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

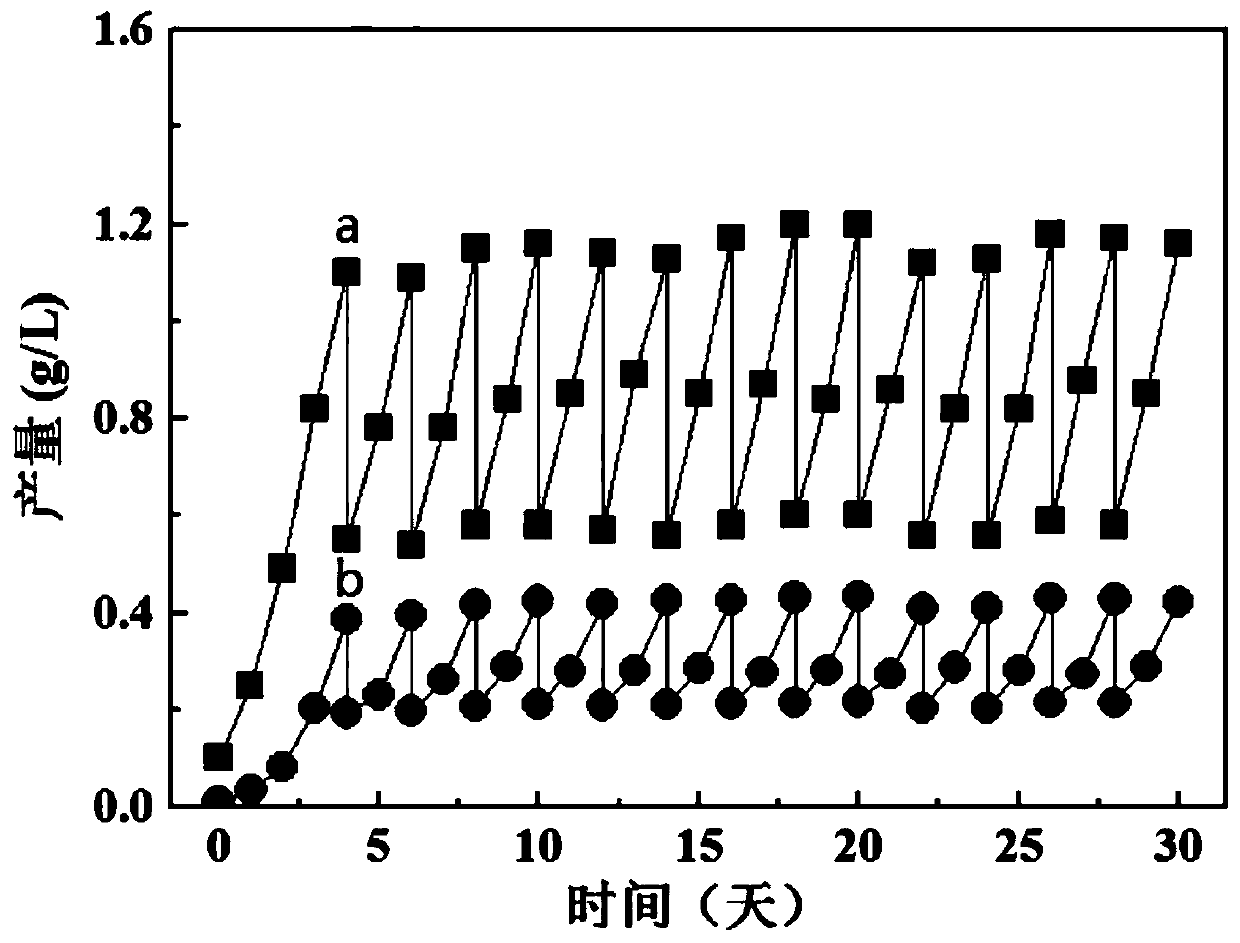

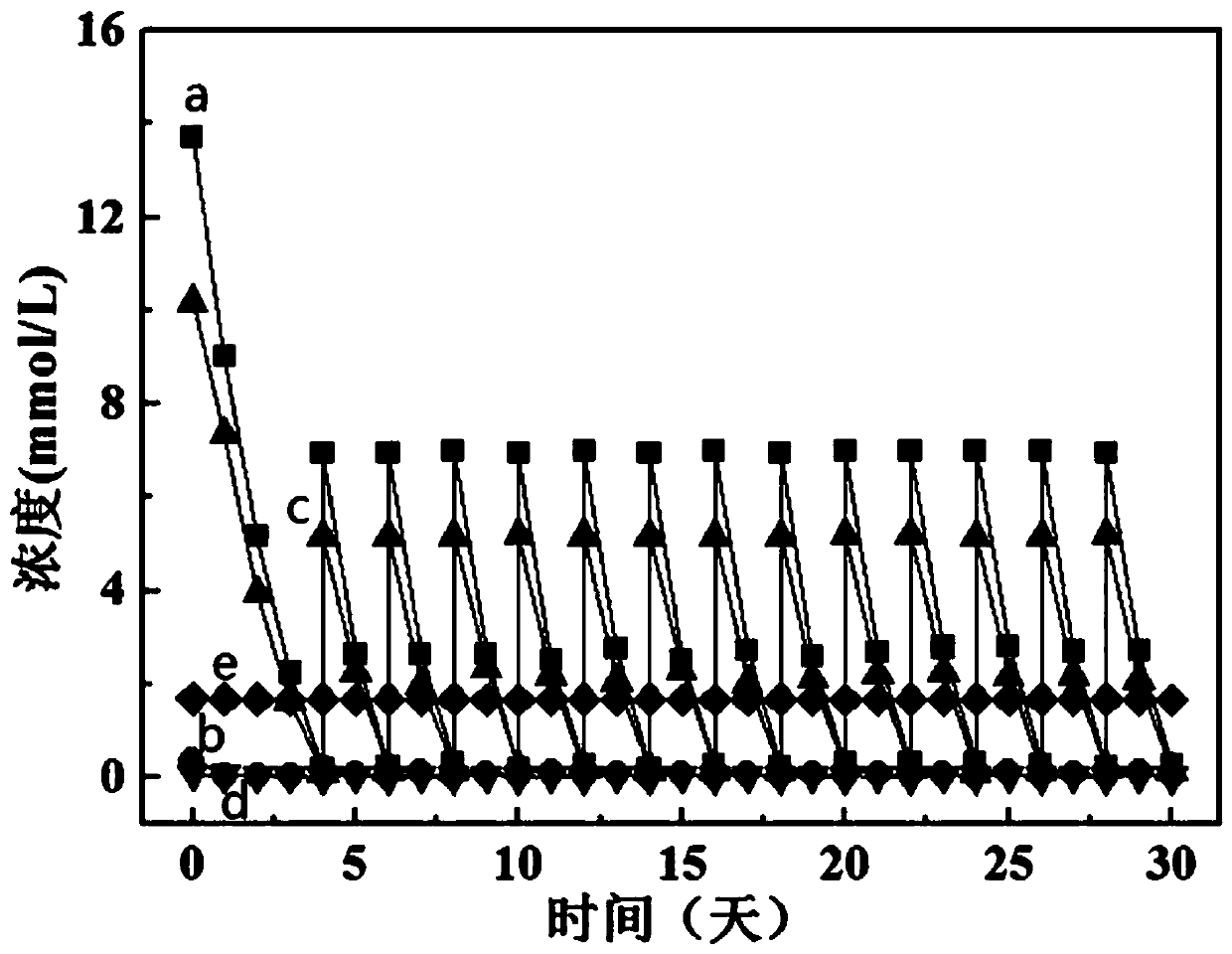

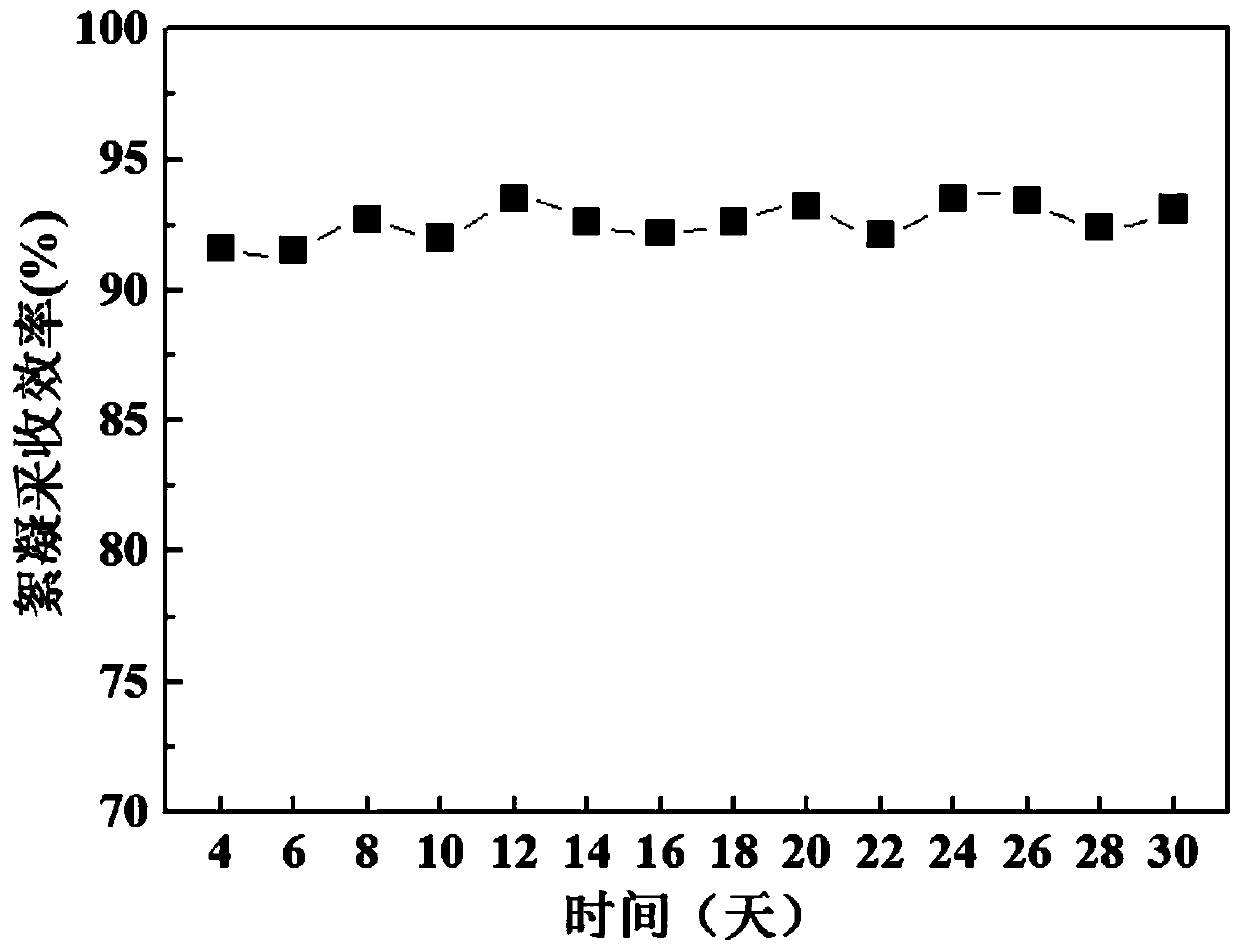

[0014] Specific Embodiment 1: A method of increasing the oil production of microalgae grown in sewage and the recovery efficiency of in-situ flocculation in this embodiment is achieved through the following steps:

[0015] 1. Add metal ions to the sewage and mix them evenly to obtain a mixed solution A; 2. Add the microalgae seed solution to the mixed solution A and ferment until the fermentation is stable; 3. After the microalgae fermentation is stable, discharge part of the microalgae Fermentation liquid, and add the same amount of mixed solution A, adjust the metal ion concentration to be the same as the metal ion concentration of the mixed solution A in step 1 by adding metal ions, continue to ferment after mixing evenly; 4, repeat step 3 0-100 times After the fermentation of step 3 is completed, or the operation of step 3 is omitted and the fermentation of step 2 is stable, the microalgae fermentation liquid is allowed to settle, and the flocs are settled to complete the h...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the sewage described in step 1 is one or more of fatty acid-containing sewage, protein sewage, carbohydrate sewage, and domestic sewage mixed in any ratio. Others are the same as the first embodiment.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the metal ion described in step one is Fe 3+ , Mg 2+ 、Al 3+ , Ca 2+ , Zn 2+ 、Cd 2+ , Mn 2+ One or more of them are mixed in any ratio. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com