Method for producing methane through straw anaerobic fermentation of promoted through combination with additives

An anaerobic fermentation and biomethane technology, applied in fermentation, biological sludge treatment, waste fuel, etc., can solve the problems of affecting the reaction stage, separate regulation, and inconvenient stages, so as to promote degradation and transformation, speed up the reaction process, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

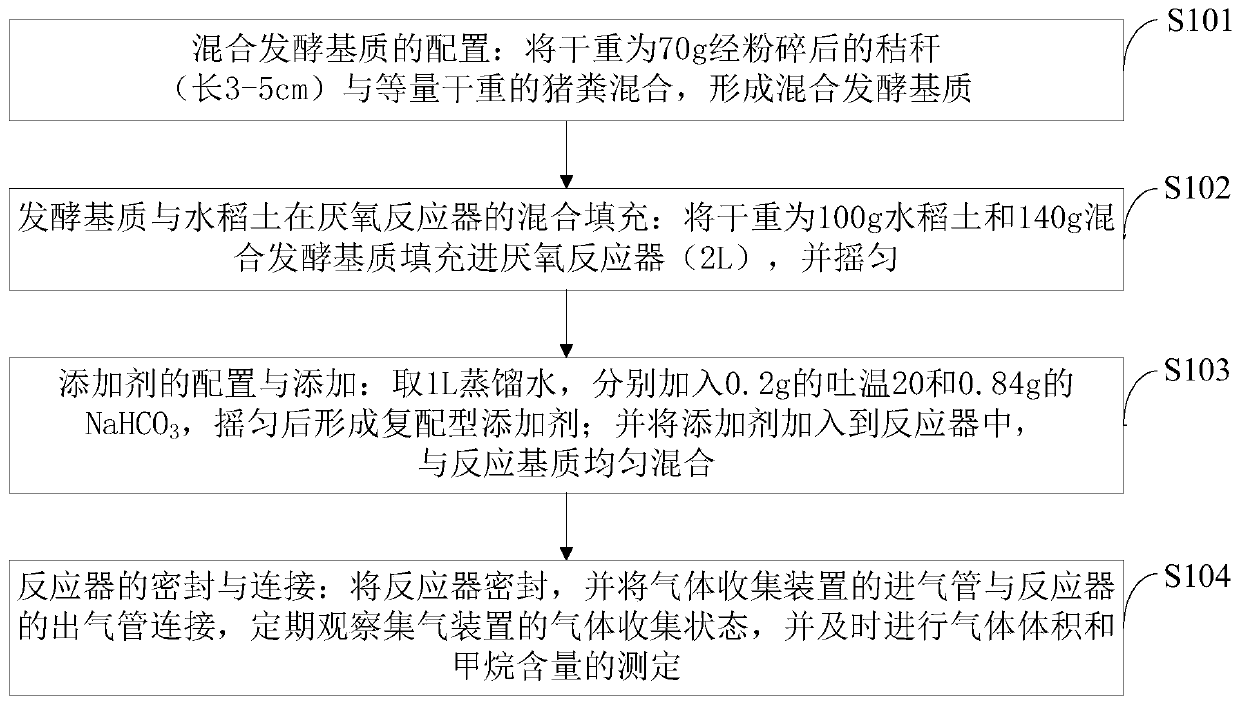

[0035] Embodiment 1: verify the effect of the present invention on the mixed fermentation and decomposition process of rice straw and pig manure, comprising the following steps:

[0036] 1) Configuration of mixed fermentation substrate: mix crushed straw (3-5 cm in length) with a dry weight of 70 g and pig manure of the same dry weight to form a mixed fermentation substrate.

[0037] 2) Mixed filling of fermentation substrate and paddy soil in the anaerobic reactor: fill the anaerobic reactor (2 L) with a dry weight of 100 g of paddy soil and 140 g of the mixed fermentation substrate, and shake well.

[0038] 3) Configuration and addition of additives: Take 1L of distilled water, add 0.2g of Tween 20 and 0.84g of NaHCO respectively 3 , and shake well to form a compound additive; add the additive into the reactor, and mix it evenly with the reaction matrix. 3 treatments were set up repeatedly, and a control group (3 repetitions) was set up.

[0039] 4) Sealing and connection ...

Embodiment 2

[0041] Embodiment 2: verify the effect of the present invention on rice straw and pig manure mixed fermentation volatile fatty acids, comprising the following steps:

[0042] 1) Configuration of mixed fermentation substrate: mix crushed straw (3-5 cm in length) with a dry weight of 70 g and pig manure of the same dry weight to form a mixed fermentation substrate.

[0043]2) Mixed filling of fermentation substrate and paddy soil in the anaerobic reactor: fill the anaerobic reactor (2 L) with a dry weight of 100 g of paddy soil and 140 g of the mixed fermentation substrate, and shake well.

[0044] 3) Configuration and addition of additives: Take 1L of distilled water, add 0.2g of Tween 20 and 0.84g of NaHCO respectively 3 , and shake well to form a compound additive; add the additive into the reactor, and mix it evenly with the reaction matrix. 3 treatments were set up repeatedly, and a control group (3 repetitions) was set up.

[0045] 4) Sealing and connection of the reacto...

Embodiment 3

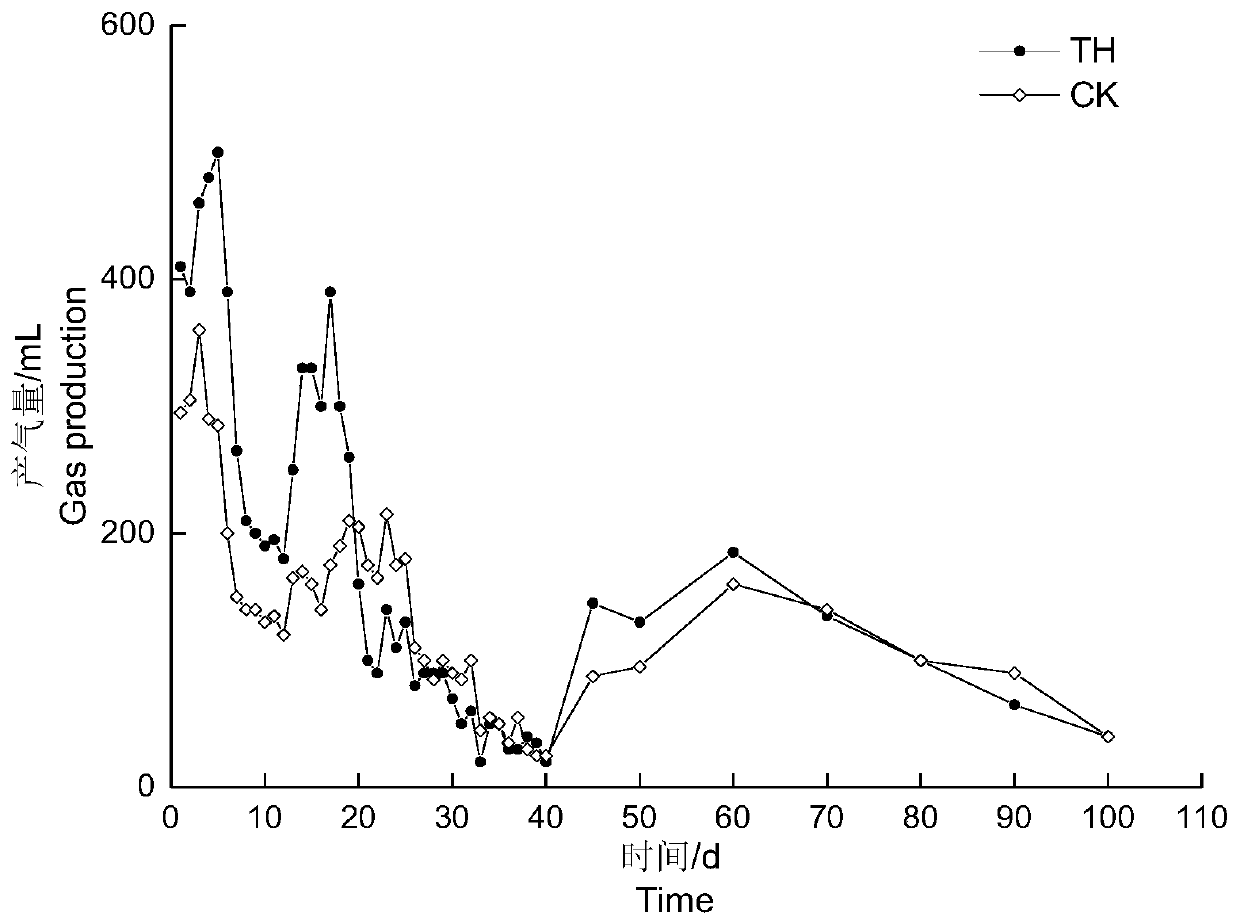

[0054] Embodiment 3: verifying the effect of the present invention on rice straw and pig manure mixed fermentation biomethane production, including the following steps:

[0055] 1) Configuration of mixed fermentation substrate: mix crushed straw (3-5 cm in length) with a dry weight of 70 g and pig manure of the same dry weight to form a mixed fermentation substrate.

[0056] 2) Mixed filling of fermentation substrate and paddy soil in the anaerobic reactor: fill the anaerobic reactor (2 L) with a dry weight of 100 g of paddy soil and 140 g of the mixed fermentation substrate, and shake well.

[0057] 3) Configuration and addition of additives: Take 1L of distilled water, add 0.2g of Tween 20 and 0.84g of NaHCO respectively 3 , and shake well to form a compound additive; add the additive into the reactor, and mix it evenly with the reaction matrix. 3 treatments were set up repeatedly, and a control group (3 repetitions) was set up.

[0058] 4) Sealing and connection of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com