Photoetching process method

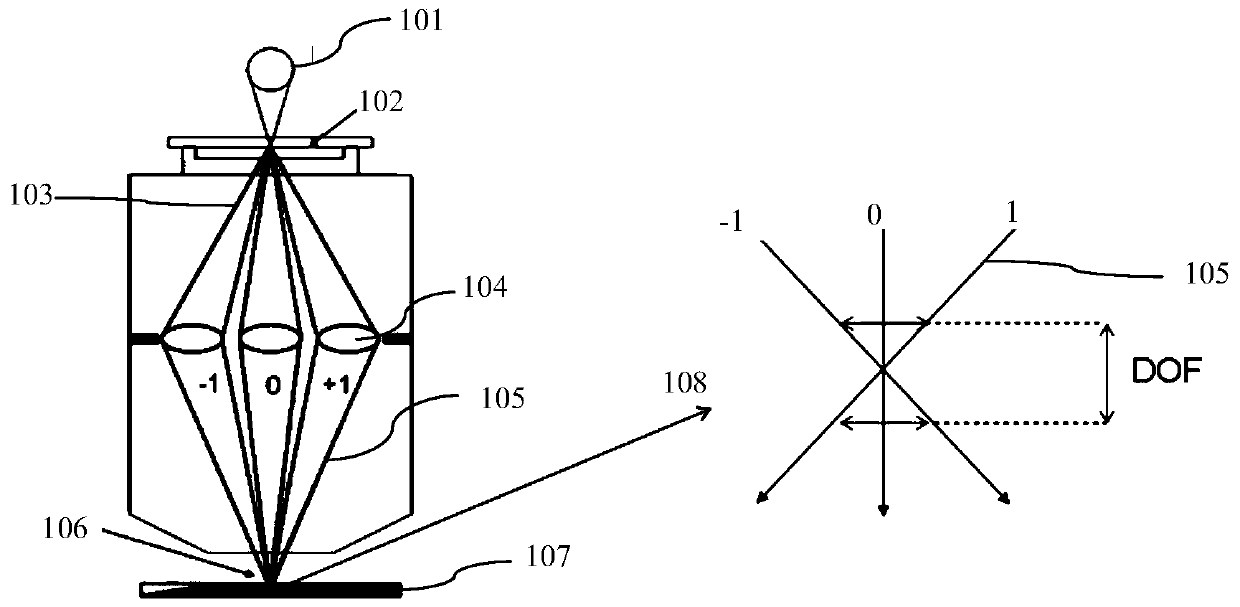

A lithography process and process technology, applied in the field of lithography process, can solve the problems of image defocus, affecting exposure resolution and process window, and high photoresist height, so as to prevent defocus, improve resolution and process window , Increase the effect of depth of focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

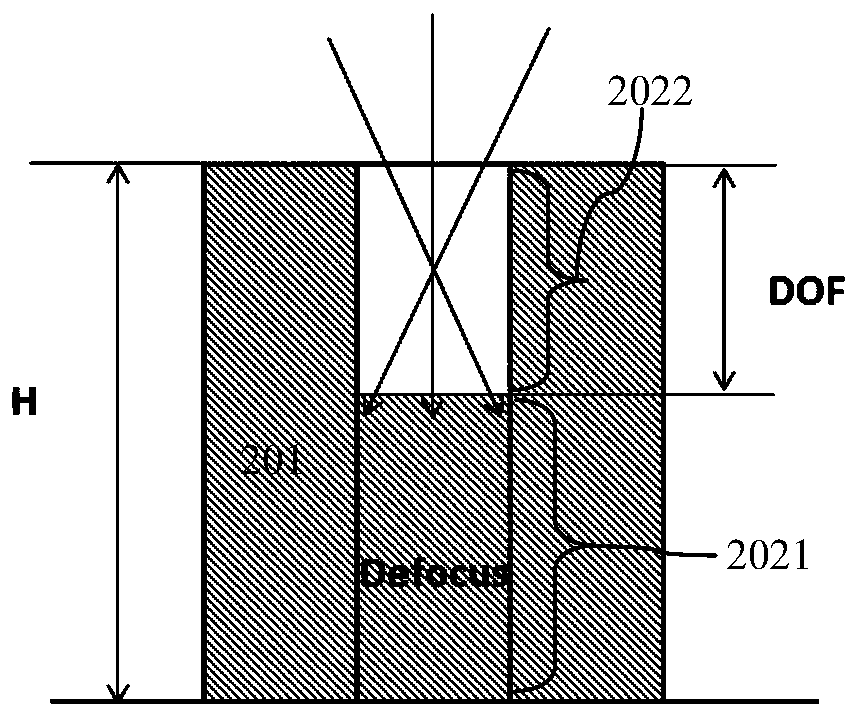

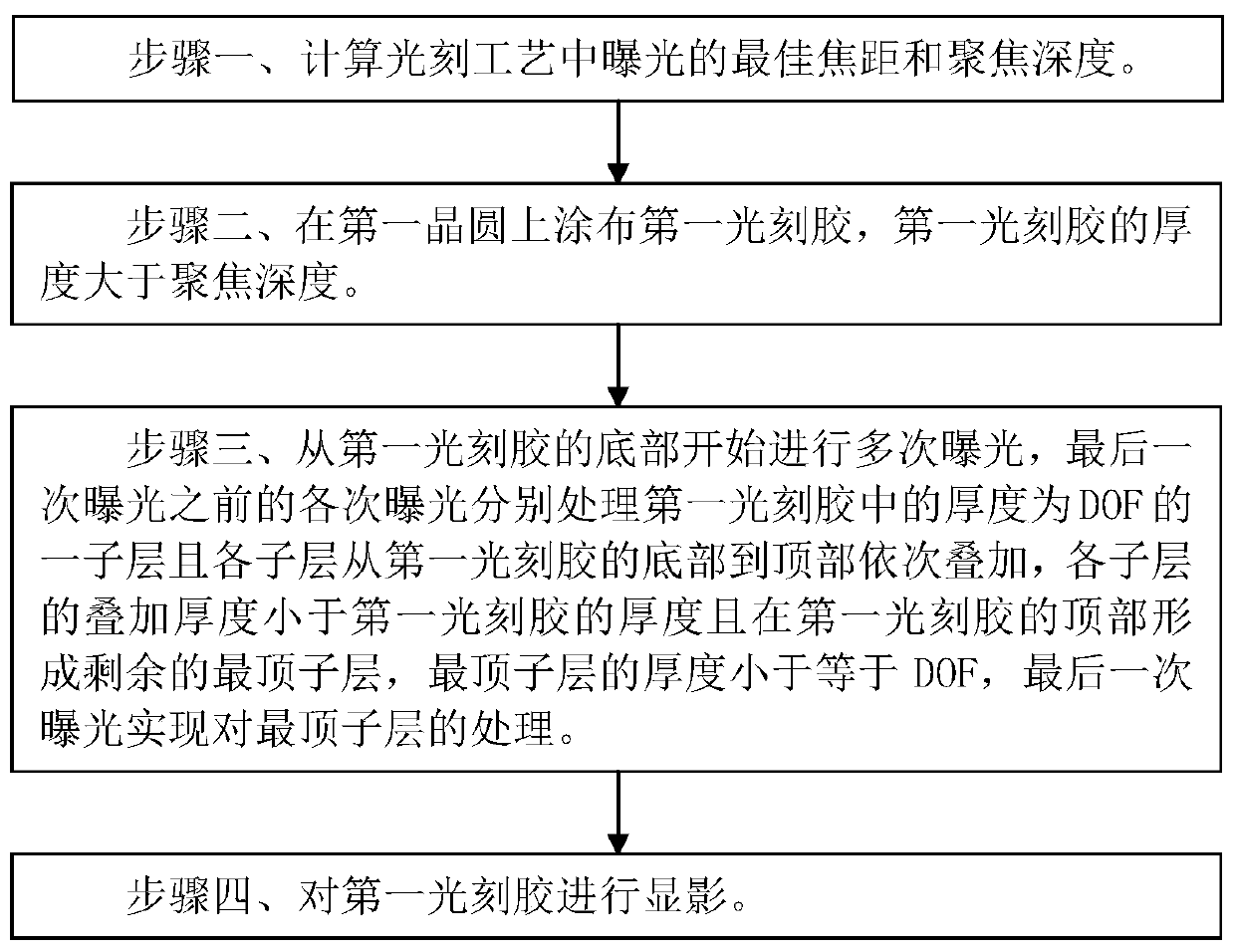

[0042] The photolithography process method of the first embodiment of the present invention:

[0043] Such as image 3 Shown is the flowchart of the photolithography process method of the first embodiment of the present invention; as Figure 4A to Figure 4B As shown, it is a schematic diagram of the photoresist structure in the exposure process of the photolithography process method of the first embodiment of the present invention; the photolithography process method of the first embodiment of the present invention includes steps:

[0044] Step 1. Calculating the optimal focal length and depth of focus of exposure in the photolithography process; let the optimal focal length be f and the depth of focus be DOF.

[0045] Step 1 is implemented in the following sub-steps:

[0046] Step 11, coating a second photoresist on the second wafer, the thickness of the second photoresist is H1, and H1 is smaller than H.

[0047] The second wafer can be the subsequent first wafer or other...

no. 2 example

[0066] The photolithography process method of the second embodiment of the present invention:

[0067] Such as Figure 5A to Figure 5C As shown, it is a schematic diagram of the photoresist structure during the exposure process of the photolithography process method of the second embodiment of the present invention; the difference between the photolithography process method of the second embodiment of the present invention and the photolithography process method of the first embodiment of the present invention Therefore, the photolithography process method in the second embodiment of the present invention has the following features:

[0068] H=nDOF and n>2, n exposures are carried out in step 3; the focal length of the kth exposure is fk, and k is any integer between 1 and n; then:

[0069] fk=f+H / 2-k*DOF.

[0070] Figure 5A Corresponding to the first exposure, the first exposure implements exposure to the sub-layer 21 in the photoresist 1 , and the thickness of the sub-la...

no. 3 example

[0077] The photolithography process method of the third embodiment of the present invention:

[0078] The difference between the lithography process method of the third embodiment of the present invention and the lithography process method of the first embodiment of the present invention is that the lithography process method of the third embodiment of the present invention has the following features:

[0079] H in step 2 is changed so that H is less than or equal to DOF; at this time, an exposure is performed in step 3, and f measured in step 1 is used for the exposure. Compared with the prior art, the advantage of the third embodiment of the present invention is that the photoresist 1 can be exposed at the best focal length, thereby increasing the process window.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com