A kind of miniled substrate packaging method

A packaging method and substrate technology, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of large number of Miniled module chips, long crystal bonding time, and affecting visual effects, so as to avoid display color distortion or smearing, The packaging method is easy to operate and avoids the effect of cross-lighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

[0043] A miniled substrate packaging method, comprising the following steps:

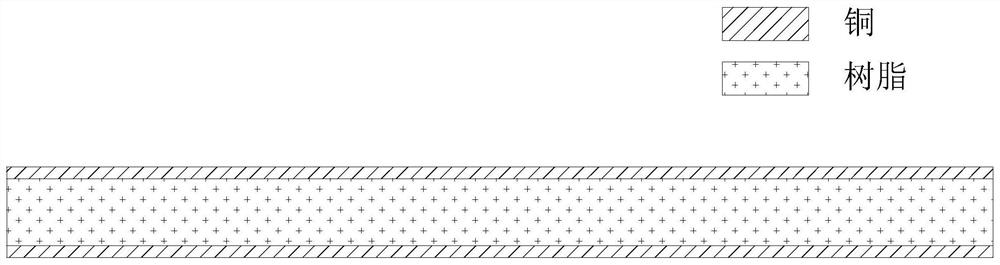

[0044] Material preparation steps (combined with figure 1 ): preparing a double-sided copper-clad laminate, the thickness of the double-sided copper-clad laminate is 100-1000 μm, and the thickness of the single-layer copper foil is 12-35 μm. Specifically, the resin layer of the double-sided copper clad laminate is BT resin. Specifically, the double-sided copper-clad laminate is an FR4 double-sided copper-clad laminate with a Tg value greater than 150 degrees Celsius.

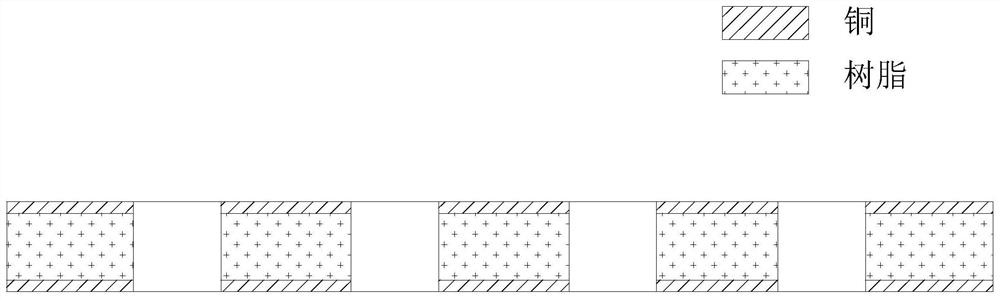

[0045] Drilling steps (combined with figure 2 ): Drill holes on the double-sided copper-clad laminate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com