Manufacturing and processing method for infant milk powder

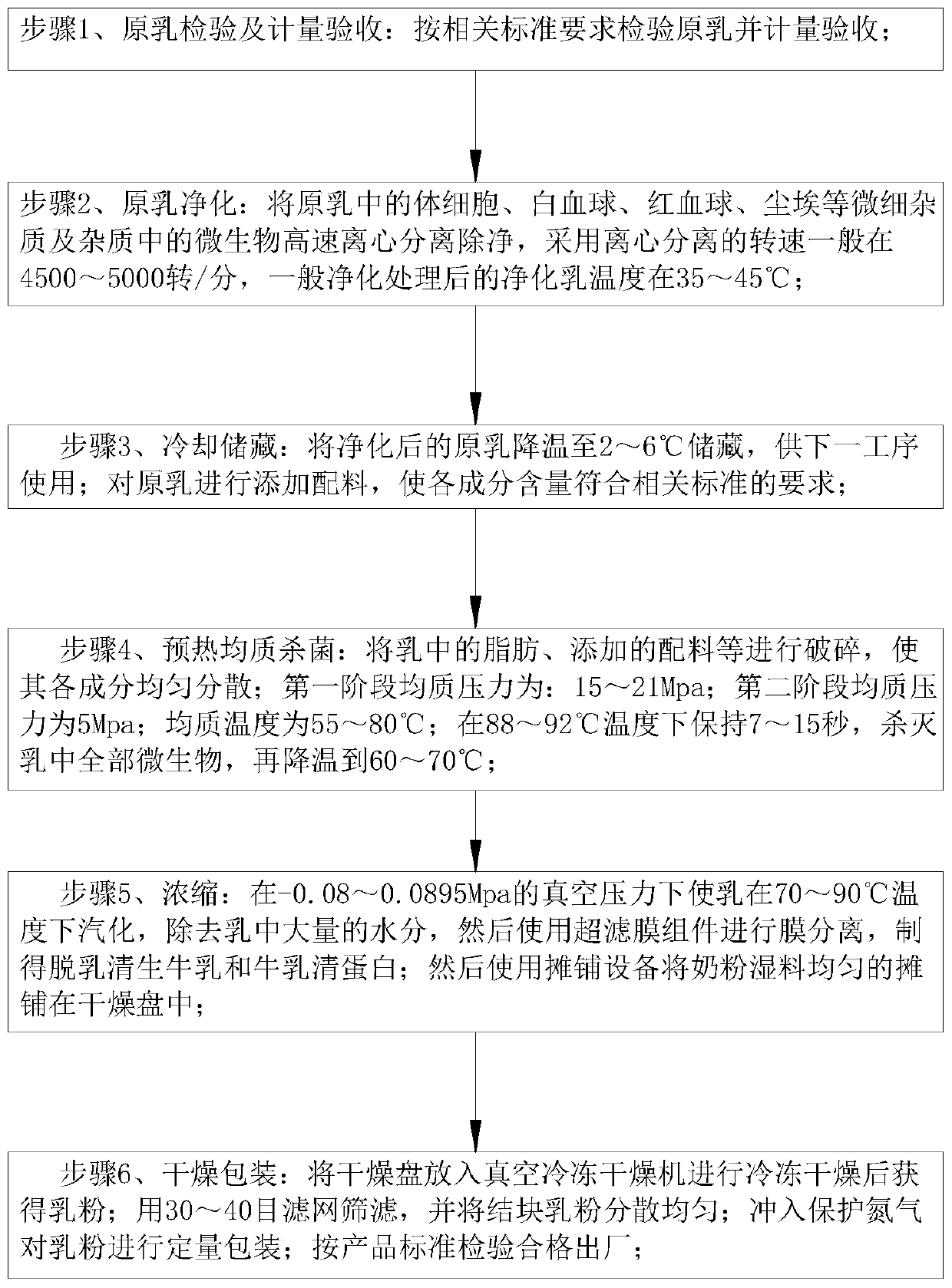

A technology for infant milk powder and processing methods, which is applied in the direction of milk preparations, dairy products, milking devices, etc., can solve the problems of reduced production efficiency, high adhesion of wet milk powder, and easy blockage of paving equipment, etc., to achieve increased Unloading speed and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

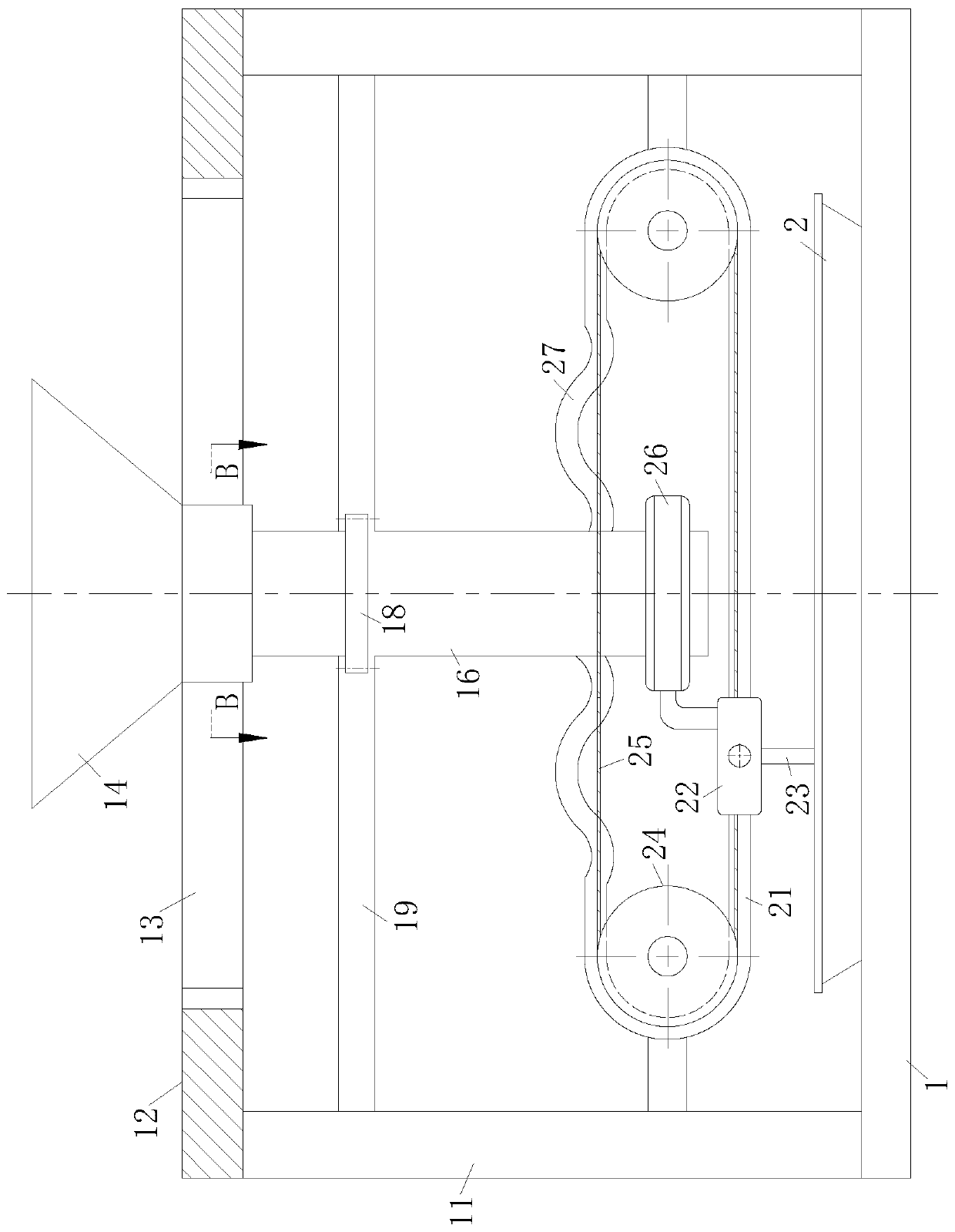

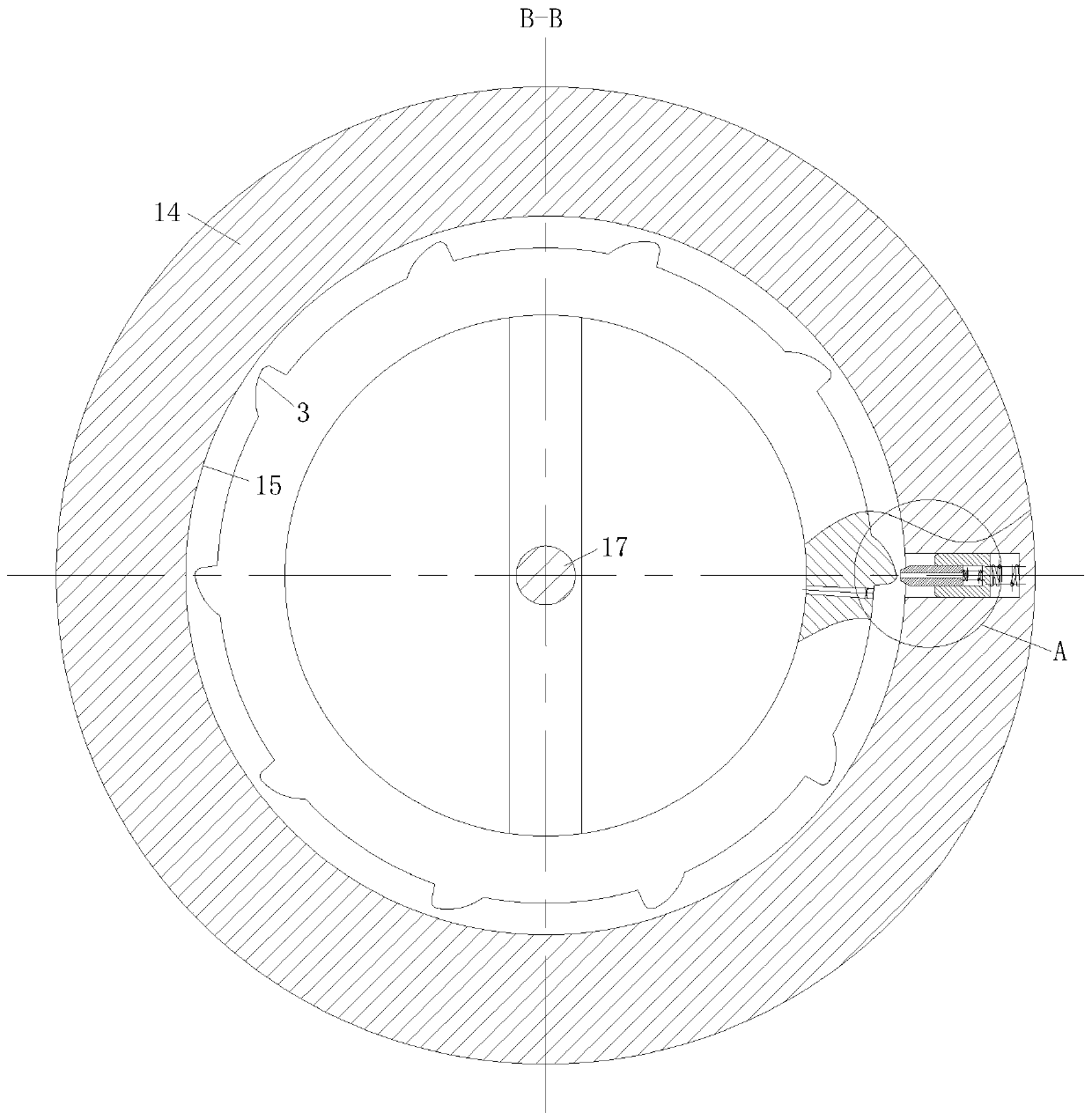

[0038] As an embodiment of the present invention, a group of protrusions 3 are evenly provided on the outer periphery of the corresponding position of the lower material cylinder 16 and the annular groove 15; There is a sliding column 32, and a spring in a compressed state is arranged between the sliding column 32 and the bottom of the sliding hole 31. Through the cooperation between the bump 3 and the sliding column 32, the sliding column 32 hits the lower barrel 16, further accelerating the wet milk powder in the hopper 14. The feeding speed; when the lower barrel 16 rotates, the lower barrel 16 drives the bump 3 to rotate in the annular groove 15, and when the bump 3 rotates to the corresponding position of the spool 32, the bump 3 squeezes the sled 32, when After the bump 3 continues to rotate, the spool 32 in the sliding hole 31 pops out under the action of the spring and hits the lower material cylinder 16, so that the lower material cylinder 16 continuously vibrates, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com