High-performance uvioresistant environment-friendly flame-retardant PC/ABS composite material and preparation method

A composite material and flame retardant technology, which is applied in the field of high-performance, UV-resistant, environmentally friendly and flame-retardant PC/ABS composite materials and their preparation, to achieve high flame-retardant performance, simple operation, flame-retardant performance and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Correspondingly, the embodiment of the present invention also provides a method for preparing a PC / ABS composite material, comprising the steps of:

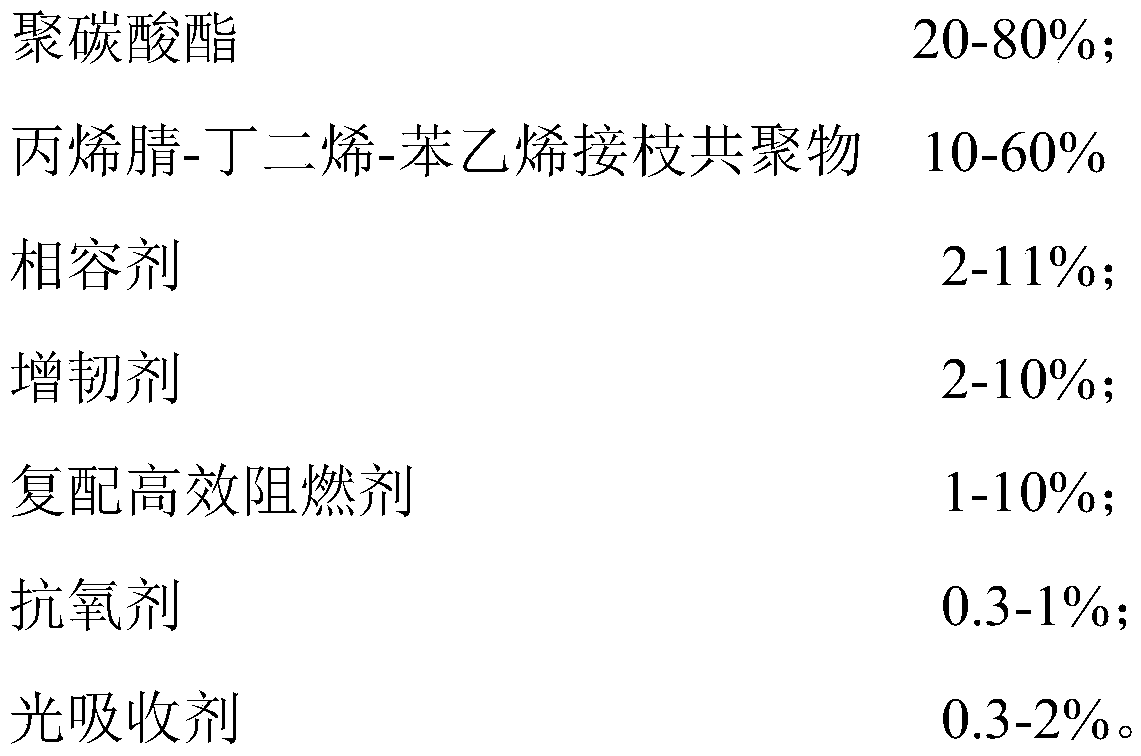

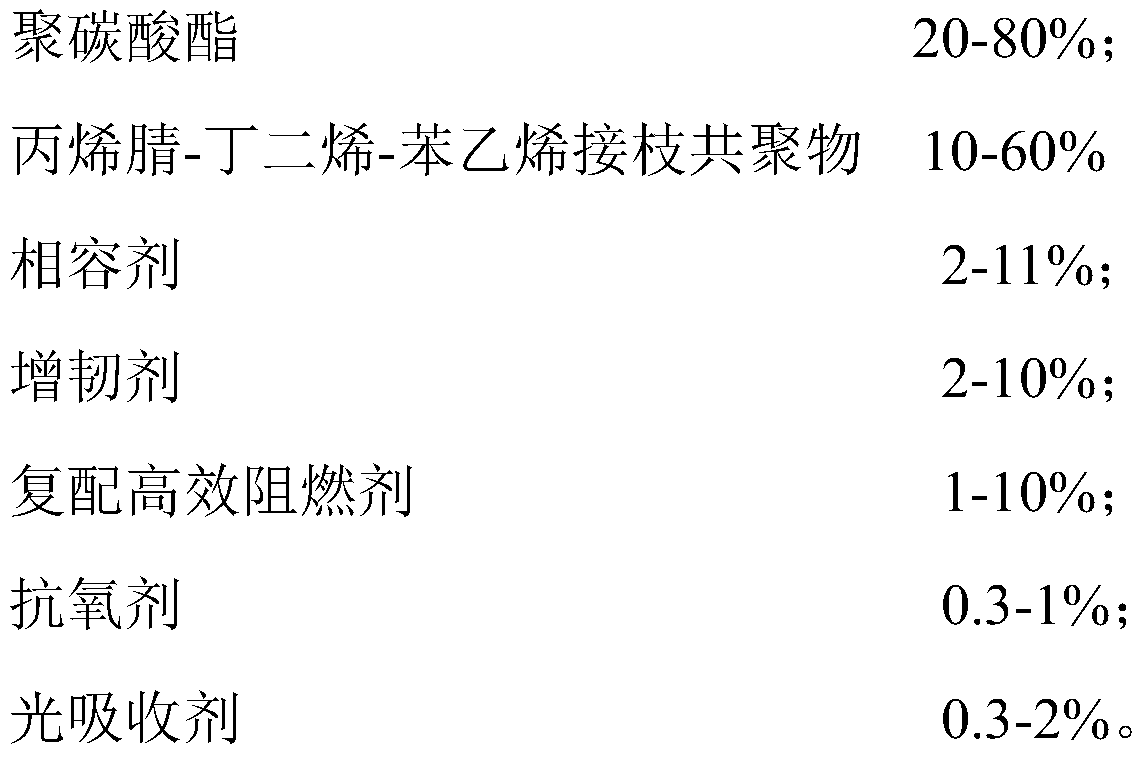

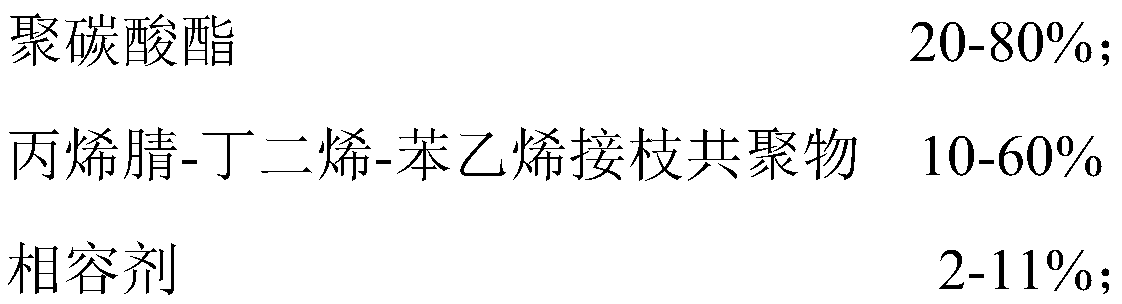

[0049] S10. Obtain the polycarbonate, acrylonitrile-butadiene-styrene graft copolymer, compatibilizer, toughening agent, compound high-efficiency flame retardant, antioxidant and light absorber in the formula quantity;

[0050] S20. Combine the polycarbonate, the acrylonitrile-butadiene-styrene graft copolymer, the compatibilizer, the toughening agent, the compound high-efficiency flame retardant, the antioxidant The light absorbing agent and the light absorbing agent are mixed and then extruded and granulated by a twin-screw extruder; wherein, the working temperature of the twin-screw extruder is 200°C-250°C, and the twin-screw speed is 250-350 rpm.

[0051] The preparation method of the PC / ABS composite material provided by the embodiment of the present invention, after mixing the raw material components of each formulat...

Embodiment 1~8

[0078] The PC / ABS composite material and rate products thereof provided by Examples 1 to 8 of the present invention are prepared according to the above-mentioned method, and the distribution ratio of each raw material component is shown in Table 1 and Table 2 below:

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com