Heat-resistant cold-resistant outdoor pressure-sensitive adhesive and preparation method thereof

A pressure-sensitive adhesive, outdoor technology, applied in the field of pressure-sensitive adhesives, can solve the problems of insufficient cold resistance and heat resistance, shedding, insufficient viscosity, etc., to improve adhesion and coating process, reduce interaction force, and improve heat resistance. The effect of cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

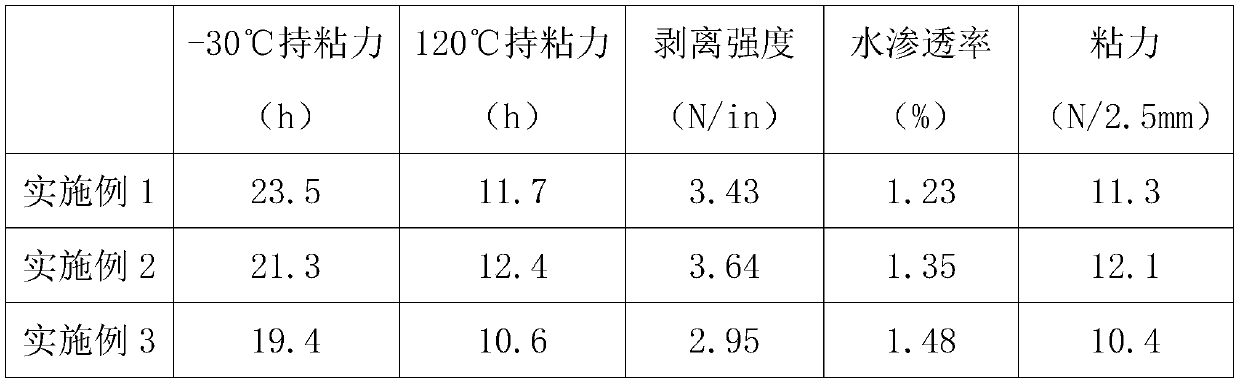

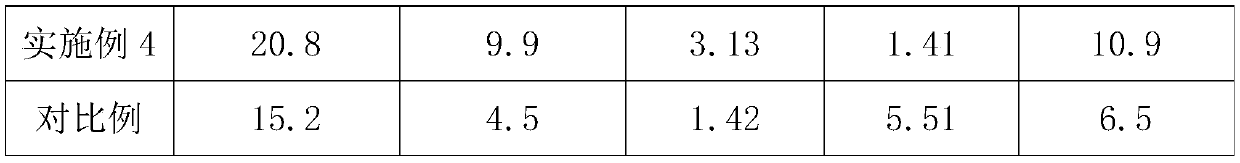

Examples

Embodiment 1

[0026] A heat-resistant and cold-resistant pressure-sensitive adhesive for outdoor use, comprising the following components and parts by weight: natural rubber, tackifying resin, plasticizer, vulcanizing agent, anti-aging agent, softener, mixed filler and titanium dioxide;

[0027] And specifically in the present embodiment, it is specifically: 125 parts of natural rubber, 125 parts of tackifying resin, 40 parts of plasticizer, 7 parts of vulcanizing agent, 7 parts of antioxidant, 7 parts of softening agent, 15 parts of mixed filler and titanium dioxide 3 copies;

[0028] Further, in the above-mentioned ingredients, the tackifying resin is specifically a mixture of rosin resin, terpene resin, maleic acid resin and water-white resin, and the rosin resin, terpene resin, maleic acid resin and water-white resin The mixing ratio is 1:3:1:1;

[0029] The viscosity of the tackifying resin is 280000mPa·s, and the softener is specifically a mixture of lanolin, lecithin, dibutyl phthal...

Embodiment 2

[0037] A heat-resistant and cold-resistant pressure-sensitive adhesive for outdoor use, comprising the following components and parts by weight: natural rubber, tackifying resin, plasticizer, vulcanizing agent, anti-aging agent, softener, mixed filler and titanium dioxide;

[0038] And specifically in the present embodiment, it is specifically: 125 parts of natural rubber, 125 parts of tackifying resin, 40 parts of plasticizer, 7 parts of vulcanizing agent, 7 parts of antioxidant, 7 parts of softening agent, 15 parts of mixed filler and titanium dioxide 3 copies;

[0039] Further, in the above-mentioned ingredients, the tackifying resin is specifically a mixture of rosin resin, terpene resin, maleic acid resin and water-white resin, and the rosin resin, terpene resin, maleic acid resin and water-white resin The mixing ratio is 1:3:1:1;

[0040] The viscosity of the tackifying resin is 250000mPa·s, and the softener is specifically a mixture of lanolin, lecithin, dibutyl phthalat...

Embodiment 3

[0048] A heat-resistant and cold-resistant pressure-sensitive adhesive for outdoor use, comprising the following components and parts by weight: natural rubber, tackifying resin, plasticizer, vulcanizing agent, anti-aging agent, softener, mixed filler and titanium dioxide;

[0049] And specifically in the present embodiment, it is specifically: 125 parts of natural rubber, 125 parts of tackifying resin, 40 parts of plasticizer, 7 parts of vulcanizing agent, 7 parts of antioxidant, 7 parts of softening agent, 15 parts of mixed filler and titanium dioxide 3 copies;

[0050] Further, in the above-mentioned ingredients, the tackifying resin is specifically a mixture of rosin resin, terpene resin, maleic acid resin and water-white resin, and the rosin resin, terpene resin, maleic acid resin and water-white resin The mixing ratio is 1:3:1:1;

[0051] The viscosity of the tackifying resin is 300000mPa·s, and the softener is specifically a mixture of lanolin, lecithin, dibutyl phthal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com