Evaporation and conveying device of metal organic chemical source liquid

A technology of metal-organic chemistry and gasification device, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of unstable metal-organic chemical sources and accumulation, and achieve good orientation, uniform surface, The effect of rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

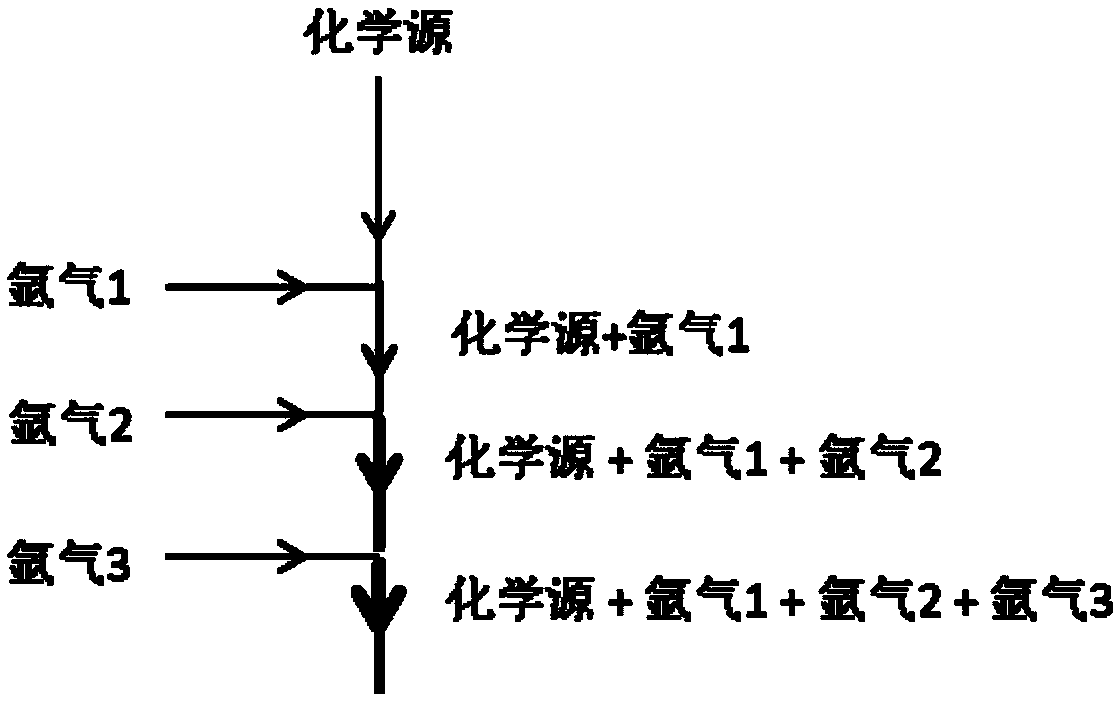

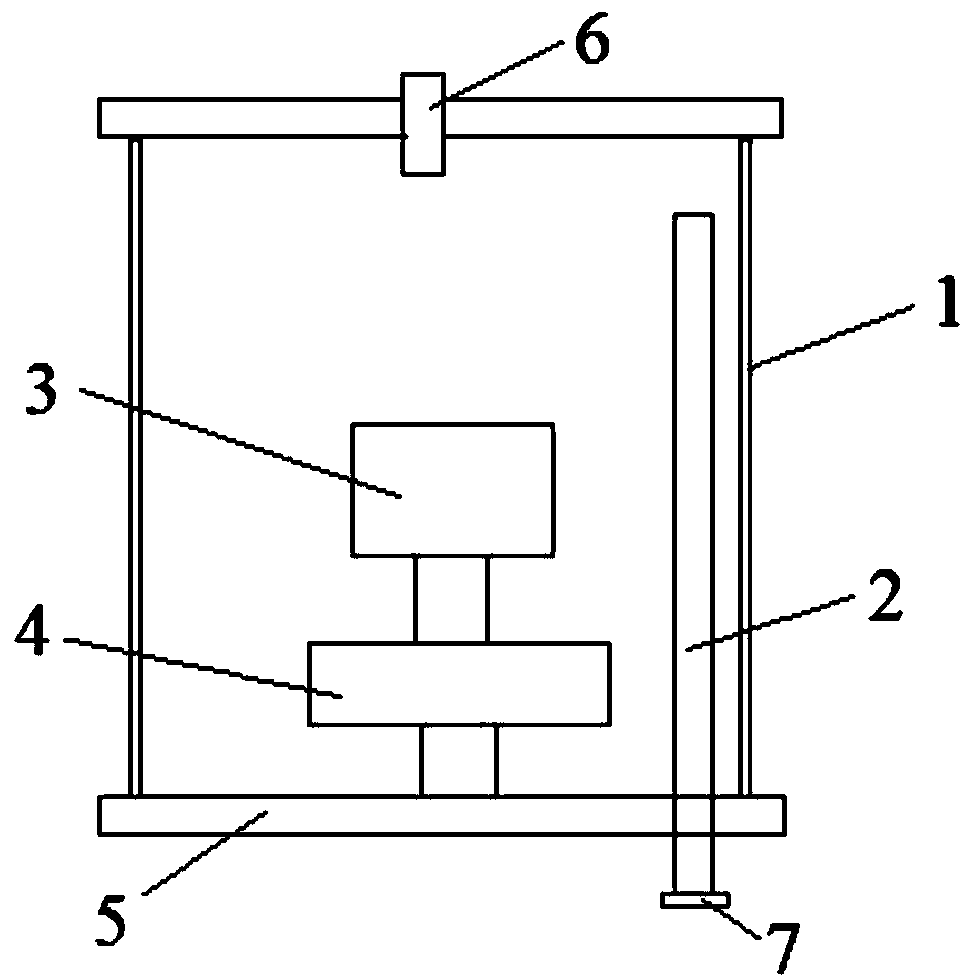

[0038] An evaporation transport device for metal organic chemical source liquid, which includes a liquid injection device and a thermal evaporation and gasification device, the liquid injection device is connected to the thermal evaporation and gasification device, and the thermal evaporation and gasification device is connected to an MOCVD chamber. Among them, the liquid injection device mixes the chemical source liquid and the carrier gas in multiple stages. The gas is mixed, thus forming a two-stage mixed gas-liquid mixed stream. According to needs, it can be mixed with the carrier gas in the pipeline of the next stage to form a multi-stage mixed gas-liquid mixed stream. The gas-liquid mixture enters the thermal evaporation gasification device.

[0039] Specifically, the gas-liquid mixed stream that enters the thermal evaporation device first hits the first-stage thermal evaporation table; the remaining liquid that is not completely evaporated on the first-stage table can ...

Embodiment 2

[0043] An evaporation transport device for metal organic chemical source liquid, specifically, a liquid injection device such as figure 1 As shown, the chemical source liquid pipe is connected to the chemical source liquid of the precision liquid pump, the first carrier gas pipe is connected with argon gas 1, the second carrier gas pipe is connected with argon gas 2, and the third carrier gas pipe is connected with argon gas 3. The gas pipe, the second carrier gas pipe and the third carrier gas pipe are respectively connected with the chemical source liquid pipe, and the chemical source liquid and argon gas 1 are mixed at the three-way junction of their pipes to form a gas-liquid mixed beam (chemical source + argon gas 1 ) into the chemical source liquid pipe is called the second-stage pipeline; it is mixed with the second carrier gas pipe (argon 2) at the next tee junction to form a gas-liquid mixed beam (chemical source + argon 1 + argon 2) The incoming chemical source liqui...

Embodiment 3

[0047] Use the evaporative transportation device of the present invention, carry out according to the following steps:

[0048] Step 1: The liquid injection device is connected to the thermal evaporation and gasification device, and the outlet of the steam outlet pipe of the thermal evaporation and gasification device is connected to the MOCVD chamber;

[0049] Step 2: heating the thermal evaporation and gasification device;

[0050] Step 3: The liquid chemical source enters the thermal evaporation and gasification device through the liquid injection device, forms steam and finally enters the reaction chamber of the MOCVD chamber to start deposition.

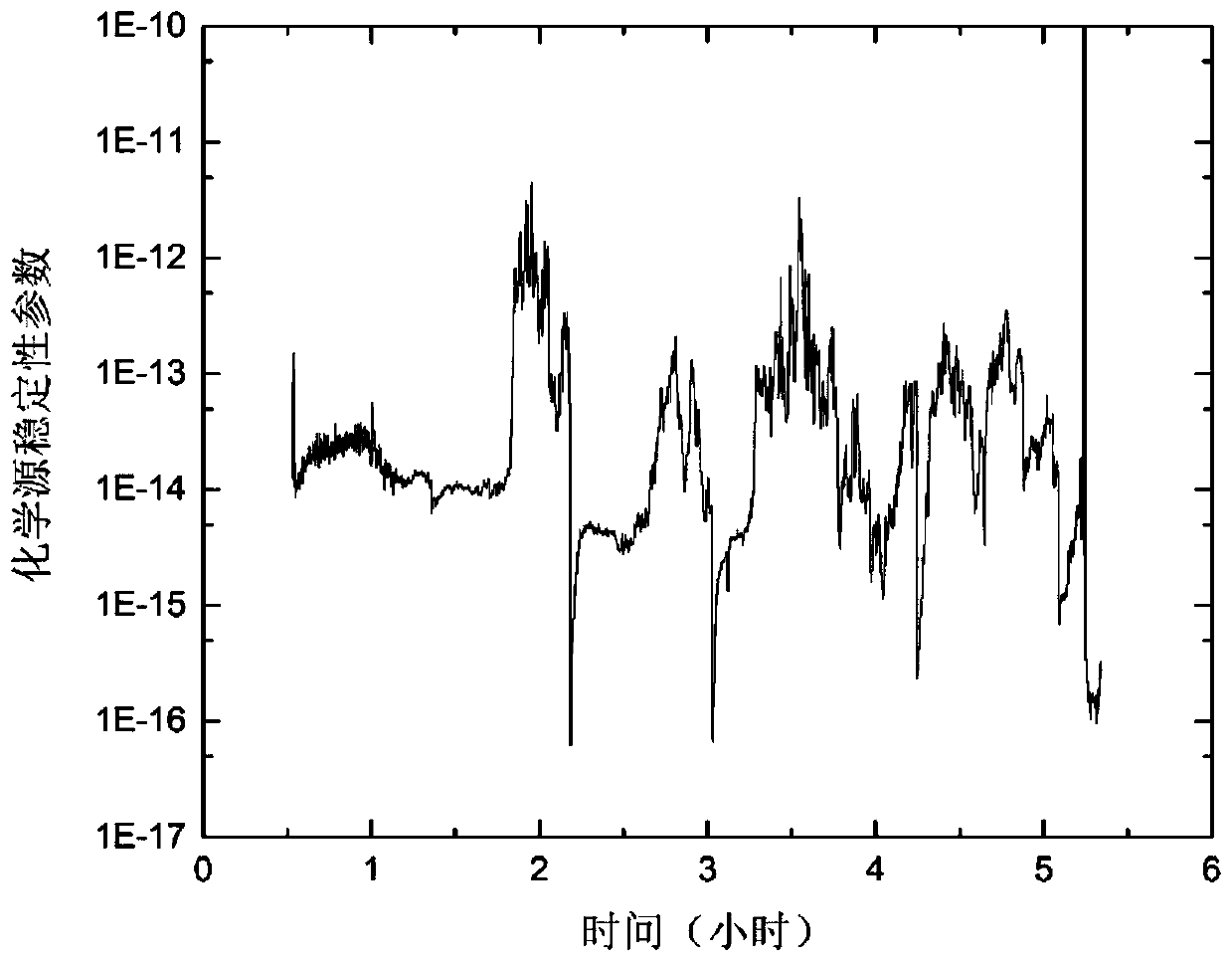

[0051] The chemical source stability identification parameter instrument is an important instrument used to monitor the stability of the system. Its response speed is fast and the detection accuracy can reach the PPM level. When the system environment changes slightly, the chemical source stability identification parameter instr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com