Large-size artificial aluminum oxide-doped colored gemstones and production method thereof

A technology of alumina and large size, which is applied in the field of large-scale artificial alumina-doped colored gemstones and its production. It can solve the problems of too small volume of colored gemstones, easy cracks, poor color, etc., and solve the problem of high proportion of air bubbles. , the burst rate is reduced, and the color is bright

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

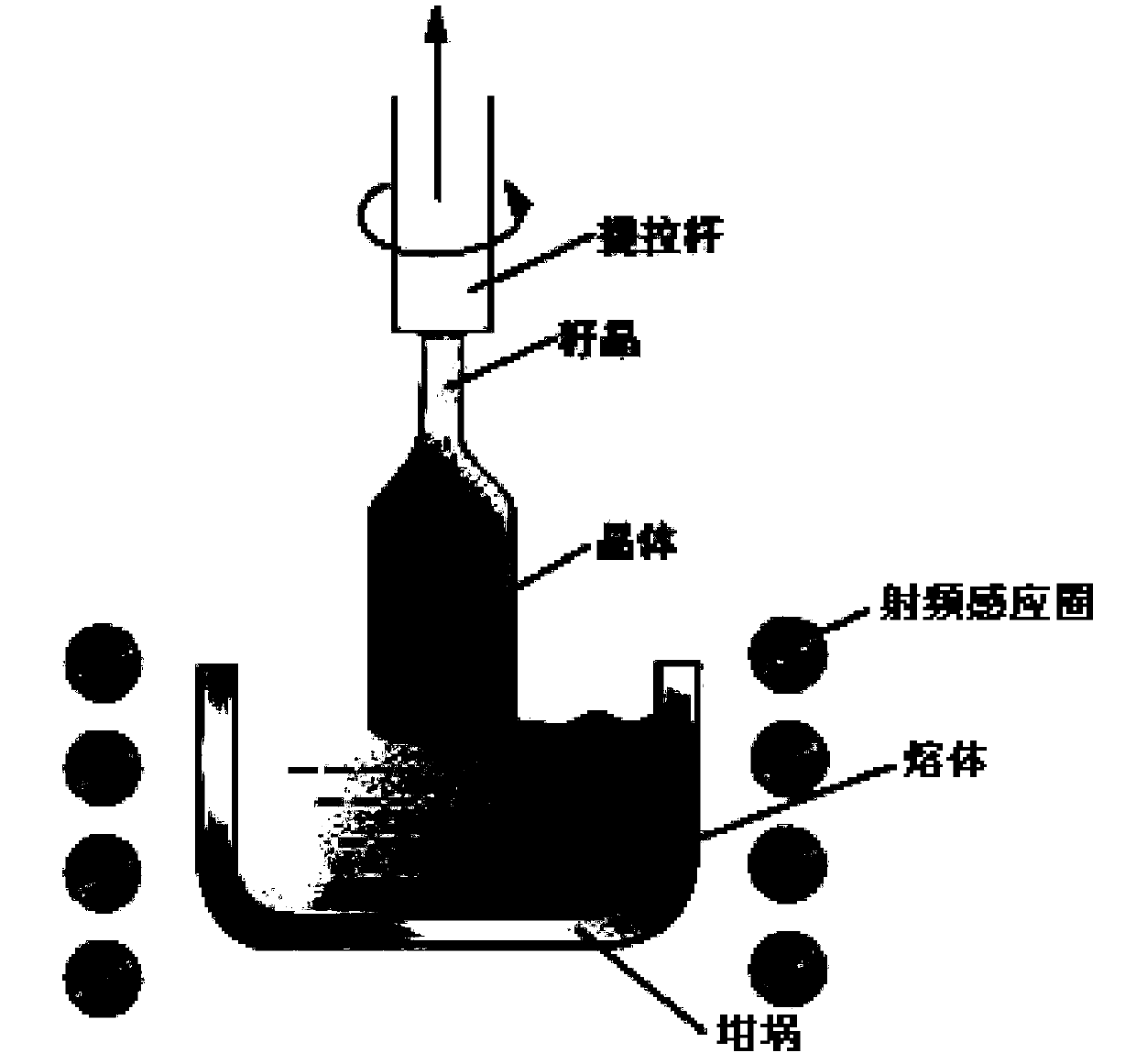

[0045] In the production of sapphire in this embodiment, the equipment type of the pulling furnace is UNC120, and an iridium crucible is selected, and copper coil induction heating is used to heat up, adjust temperature, grow, and cool down the raw materials and doping elements.

[0046] The raw material composition of sapphire is as follows: purity 99.99% block Al 2 o 3 , purity 99.99% powdered Fe 2 o 3 , purity 99.9% powdered Ti 2 o 3 , Fe 2 o 3 The weight accounted for Al 2 o 3 5‰ of weight, Ti 2 o 3 The weight accounted for Al 2 o 3 1‰ of weight, Al 2 o 3 It is block transparent raw material of flame method.

[0047] The production method comprises the following steps:

[0048] 1) Furnace loading: Clean the furnace and furnace shell of the equipment, check the insulation performance of the furnace and insulation bricks, adjust the position of the crucible to ensure that the crucible is stable and in the middle of the furnace; charge according to the designed...

Embodiment 2

[0057] In this embodiment, sapphire is produced. The equipment model of the pulling furnace is AJAX-PACERS. The iridium crucible is selected, and the copper coil induction heating is used to perform the steps of heating, temperature adjustment, growth, and cooling of raw materials and doping elements.

[0058] The raw material composition of sapphire is as follows: purity 99.99% block Al 2 o 3 , purity 99.9% powdered Fe 2 o 3 , purity 99.9% powdered Ti 2 o 3 , Fe 2 o 3 The weight accounted for Al 2 o 3 5‰ of weight, Ti 2 o 3 The weight accounted for Al 2 o 3 0.7‰ of weight, Al 2 o 3 It is block transparent raw material of flame method.

[0059] The production method comprises the following steps:

[0060] 1) Furnace loading: Clean the furnace and furnace shell of the equipment, check the insulation performance of the furnace and insulation bricks, adjust the position of the crucible to ensure that the crucible is stable and in the middle of the furnace; charge a...

Embodiment 3

[0066] In this embodiment, red gemstones are produced. The equipment model of the pulling furnace is AJAX. The iridium crucible is selected, and the copper coil induction heating is used to perform the heating, temperature adjustment, growth, and cooling steps of the raw materials and doping elements.

[0067] The raw material composition of sapphire is as follows: purity 99.99% block Al 2 o 3 , purity 99.95% powdered Cr 2 o 3 , purity 99.9% powdered Ti 2 o 3 , Cr 2 o 3 The weight accounted for Al 2 o 3 5‰ of weight, Ti 2 o 3 The weight accounted for Al 2 o 3 0.5‰ of weight, Al 2 o 3 It is block transparent raw material of flame method.

[0068] The production method comprises the following steps:

[0069] 1) Furnace loading: Clean the furnace and furnace shell of the equipment, check the insulation performance of the furnace and insulation bricks, adjust the position of the crucible to ensure that the crucible is stable and in the middle of the furnace; charge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com