Method for manufacturing a polyurethane urea elastic fiber having antibacterial and deodorizing functions, and a polyurethane urea elastic fiber manufactured thereby

A polyurethane urea, elastic fiber technology, applied in the direction of single-component polyurethane rayon, rayon manufacturing, textiles and papermaking, etc., can solve the problems of smell, discoloration, difference in antibacterial properties, etc., and achieve increased antibacterial and deodorizing functions. , the effect of minimizing local color changes and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

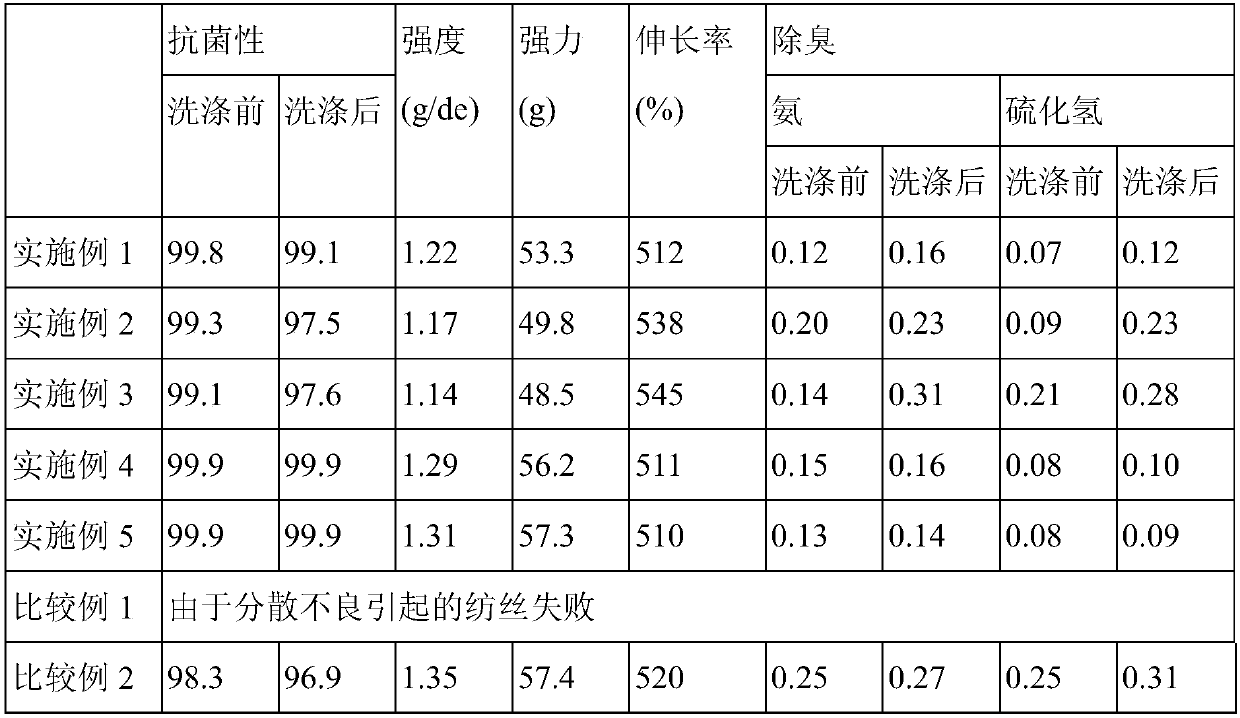

Examples

Embodiment 1

[0116] 1) Use a quantitative pump to continuously transfer polytetramethylene ether glycol (molecular weight 1800) 156.31g / min and diphenylmethane-4,4'-diisocyanate 36.96g / min to a 40°C homogeneous mixer (Static Mixer) and mixed, put into a continuous polymerization tube in the form of a cylindrical tube at 80°C, reacted for 135 minutes, adjusted the reaction so that the terminal unreacted diisocyanate became 2.64 ± 0.02 mol%, and synthesized as a primary polymer polyurethane prepolymers.

[0117] Cool the above-mentioned primary polymer to 40°C and stabilize it within 24 hours, and then put it into the high-shear mixer continuously with N,N-dimethylacetamide 309.93g / min immediately before putting it into the secondary reactor , stirred vigorously at 3500 rpm for 20 seconds. The above-mentioned primary polymer was completely dissolved and cooled to prepare a polyurethane polymer solution having a solid content of 38.27% by weight at 40°C.

[0118] 2) 4.984 kg of ethylenediam...

Embodiment 2

[0125] In Example 1, the reaction was adjusted so that the terminal unreacted diisocyanate became 2.24±0.02 mol%, and the polyurethane prepolymer which is a primary polymer was synthesize|combined, It implemented by the same method.

Embodiment 3

[0127] In Example 1, the reaction was adjusted so that the terminal unreacted diisocyanate became 3.65±0.02 mol%, and the polyurethane prepolymer which is a primary polymer was synthesize|combined, It implemented by the same method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com