Manufacturing method for porous polymerizing master batch with antibacterial and deodorizing function and fiber

A manufacturing method and porosity technology, which is applied in the field of antibacterial and deodorant polymer masterbatch and its fiber manufacturing, can solve the problems of easy loss, allergic reaction of users, easy to be washed off, etc., to increase antibacterial deodorization and not easy to lose , broad-spectrum antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

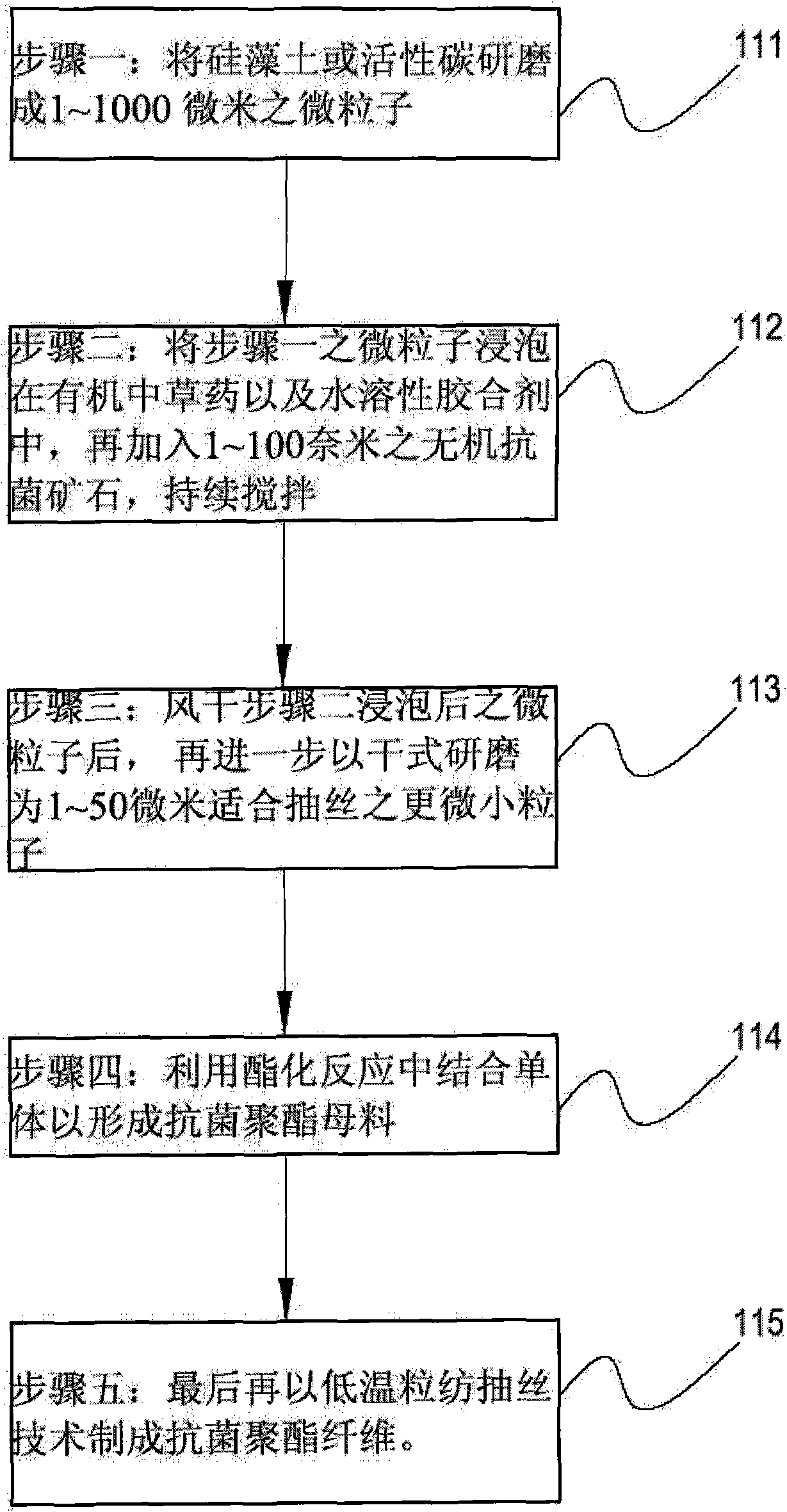

[0023] see figure 1 , the manufacture method of porous polymer masterbatch and fiber with antibacterial and deodorizing functions of the present invention comprises the following steps:

[0024] Step 1: Grinding diatomaceous earth or activated carbon into fine particles (111) of 1-1000 microns (micron);

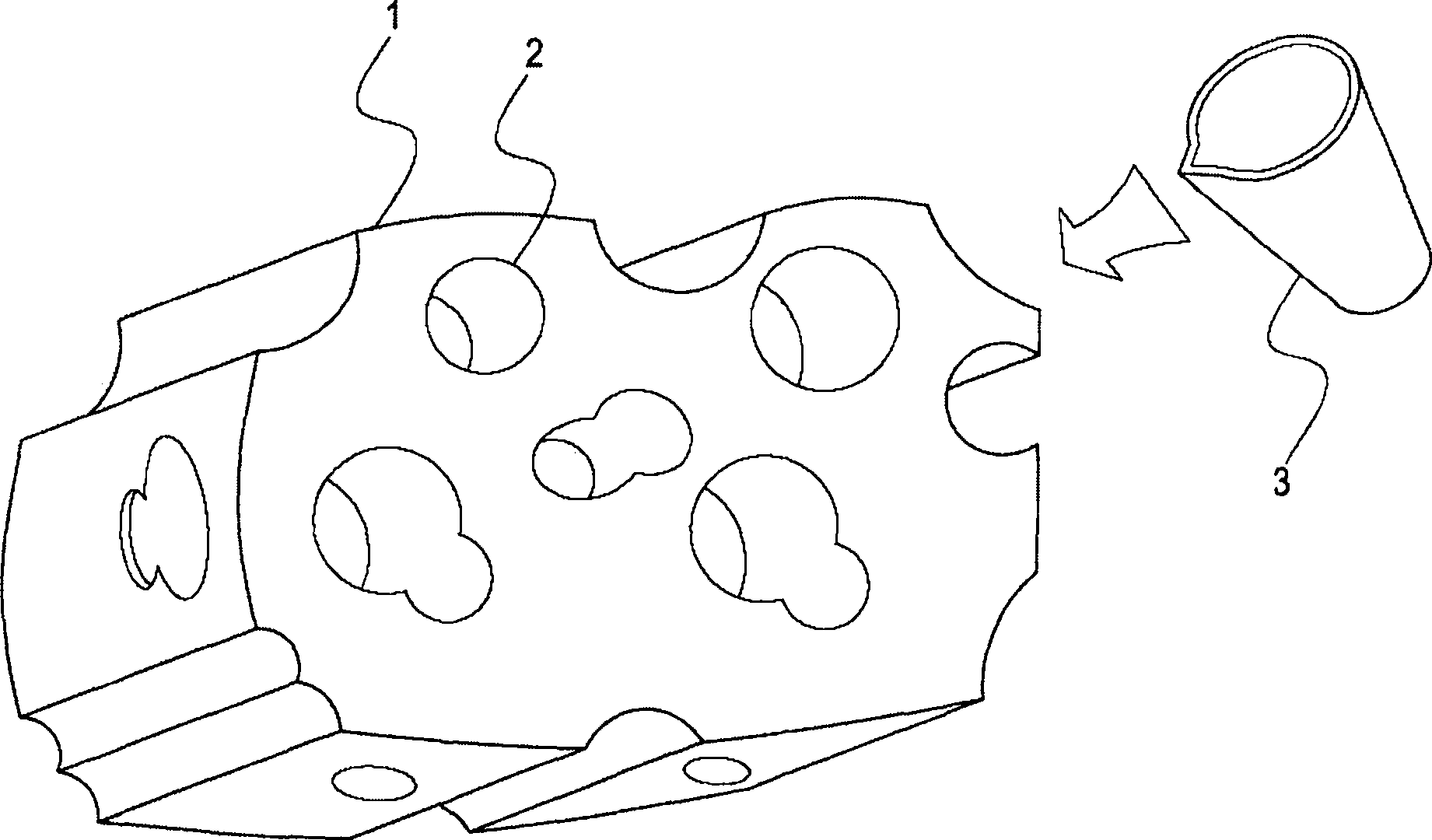

[0025] ●See figure 2 diatomite or activated carbon microparticles, step 1 firstly grind diatomite or activated carbon into microparticles 1. Taking activated carbon as an example, its main component is carbon, mixed with a small amount of hydrogen, oxygen, nitrogen, sulfur, etc. It is a black porous substance with a complex surface, and its structure is a hexacyclic ring formed by carbon. The particle shape can range from cylindrical coarse particles to fine powder particles, so there are two types of granular and powdery. The particle diameter is generally 1-6mm, and the length is about 0.7-4 times the diameter, or 6-120 Irregular particles with mesh size. Activated car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com