Novel municipal road pipe network and construction process

A new type of municipal and pipe network technology, applied in the waterway system, sewer pipe system, pipe laying and maintenance, etc., can solve the problems of pipeline cracking, pipeline damage, and thermal pipe network without burying, so as to avoid aging and corrosion, The effect of not being damaged easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

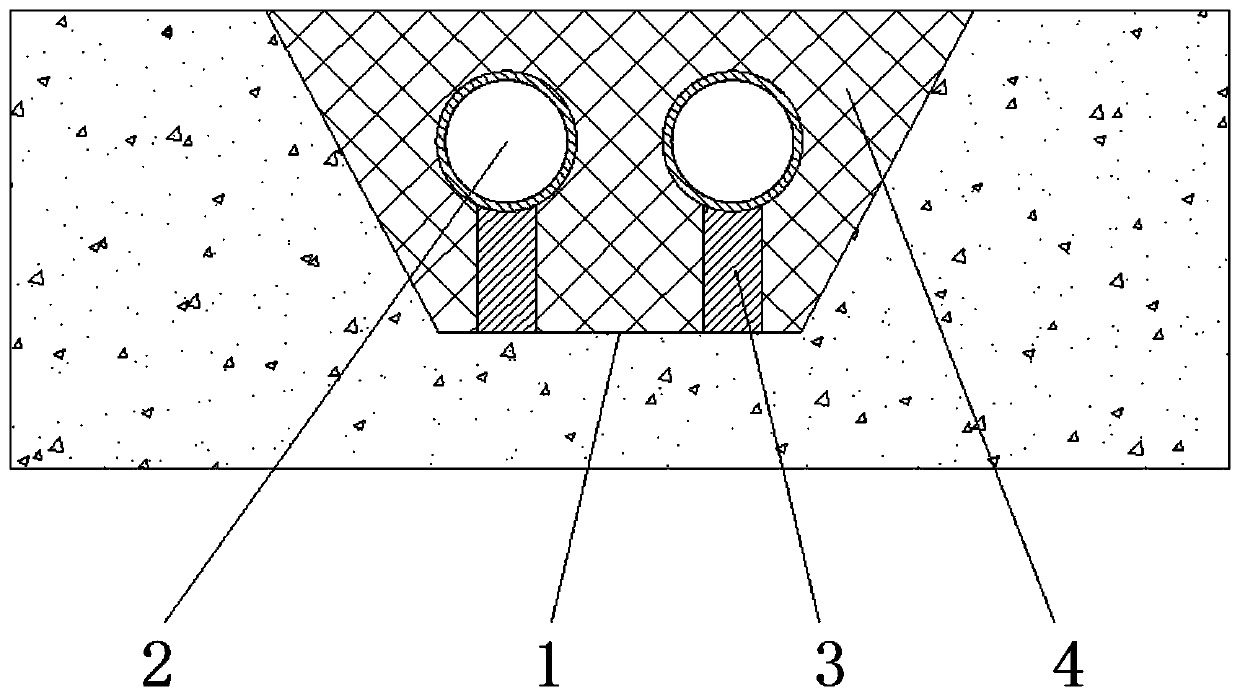

[0029] See figure 1 , the new municipal pipeline network in the present invention has a pipeline trough 1 and a pipeline 2 laid in the pipeline trough 1; a plurality of support blocks 3 for supporting the pipeline 2 are arranged in the pipeline trough 1 along its extending direction; The pipeline groove 1 is filled with geopolymer foamed concrete 4 .

[0030] The support block 3 is a geopolymer foamed concrete prefabricated part.

[0031] The construction technique for laying the above-mentioned novel municipal pipeline network of the present invention comprises the following steps;

[0032] S1, digging the pipeline groove 1;

[0033] S2, laying the pipeline 2 in the pipeline groove 1;

[0034] S3, pouring the geopolymer foam concrete 4 to fill the pipeline trench 1 .

[0035] The components of the geopolymer foam concrete 4 are as follows by mass percentage:

[0036] Steel slag powder: 45%, modified red mud: 5%; modified metakaolin: 25%; class I fly ash: 16.18%; coagulan...

Embodiment 2

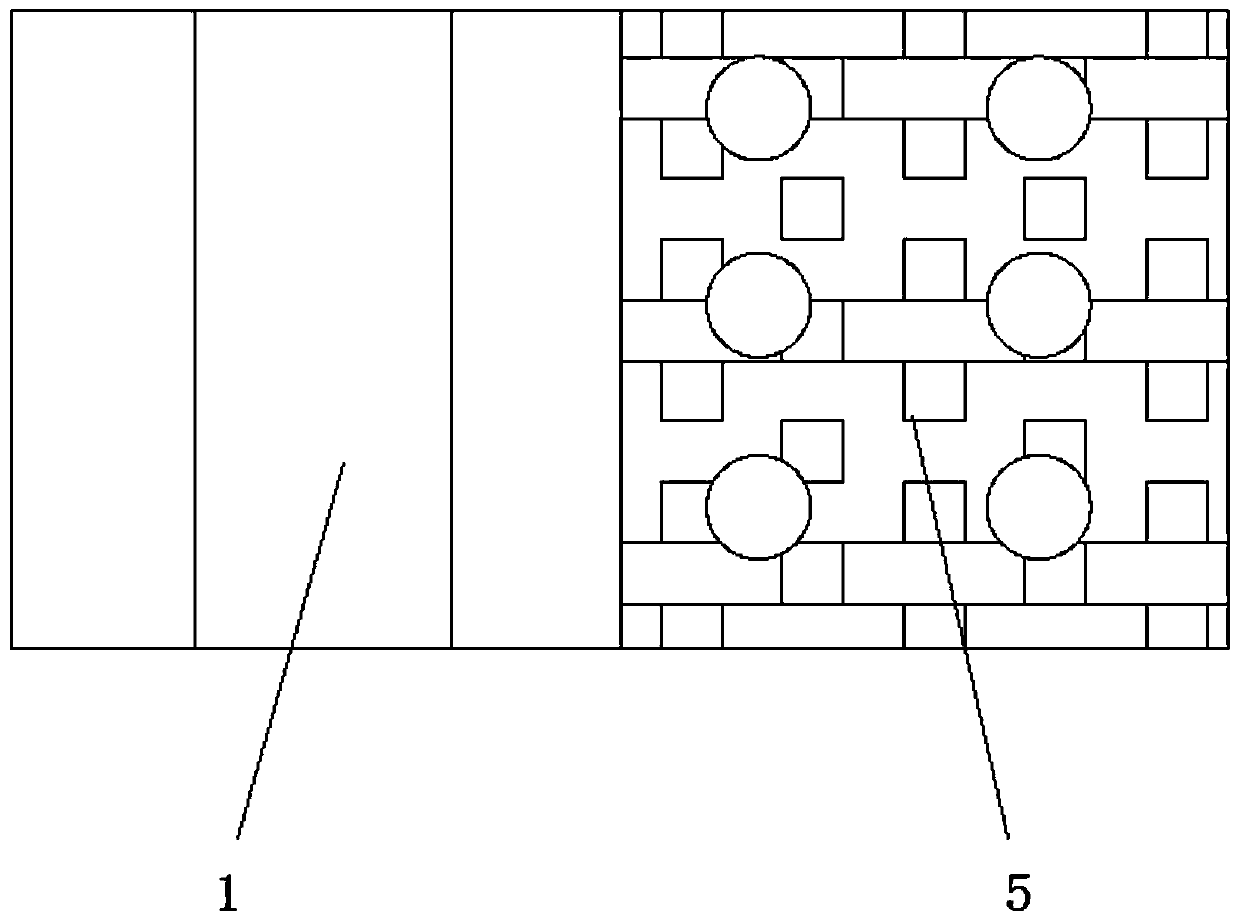

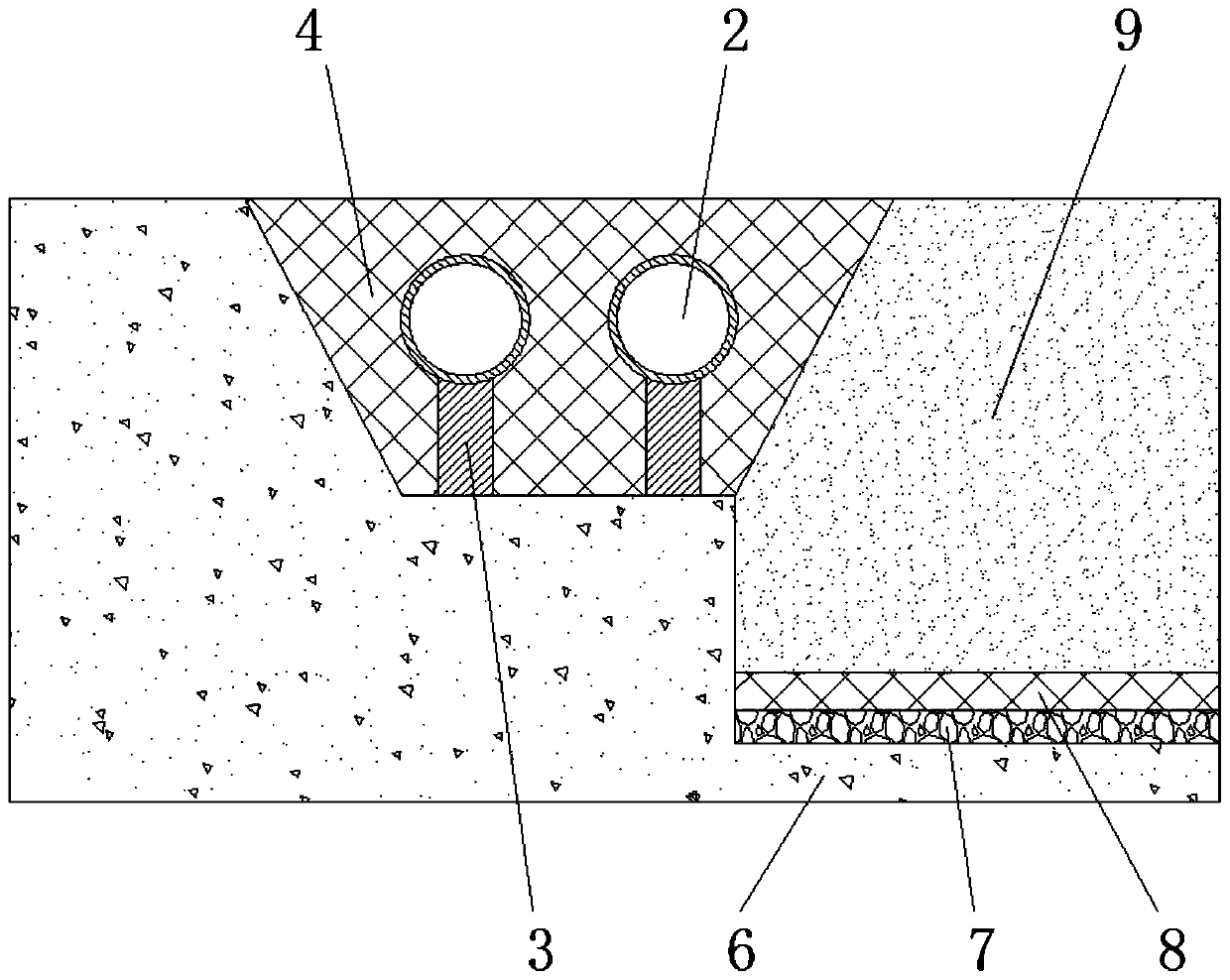

[0038] See figure 2 with image 3 In the present invention, the new municipal pipeline network has a pipeline trough 1, and the pipeline trough 1 is adjacent to the green belt 5, and a plurality of support blocks 3 for supporting the pipeline 2 are arranged in the pipeline trough 1 along its extension direction, and the pipeline 2 It is arranged in the pipeline trough 1; the pipeline trough 1 is filled with geopolymer foamed concrete 4.

[0039] The support block 3 is a geopolymer foamed concrete prefabricated part.

[0040] The green belt 5 includes a foundation 6, a cushion layer 7, a geopolymer foam concrete layer 8 and a filling layer 9 from bottom to top.

[0041] The cushion layer 7 is a gravel pavement layer.

[0042] The geopolymer foamed concrete layer 8 of the green belt 5 is lower than the bottom surface of the pipeline trough 1 . The geopolymer foam concrete 4 in the pipeline channel 1 is in direct contact with the filling soil layer 9 of the green belt 5 .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com