Standard template for nanometer measurement instrument calibration and preparation method thereof

A technology for measuring instruments and standard templates, applied in instruments, measuring devices, scanning probe microscopy, etc., to achieve great application value, improve the efficiency of calibration, and achieve the effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

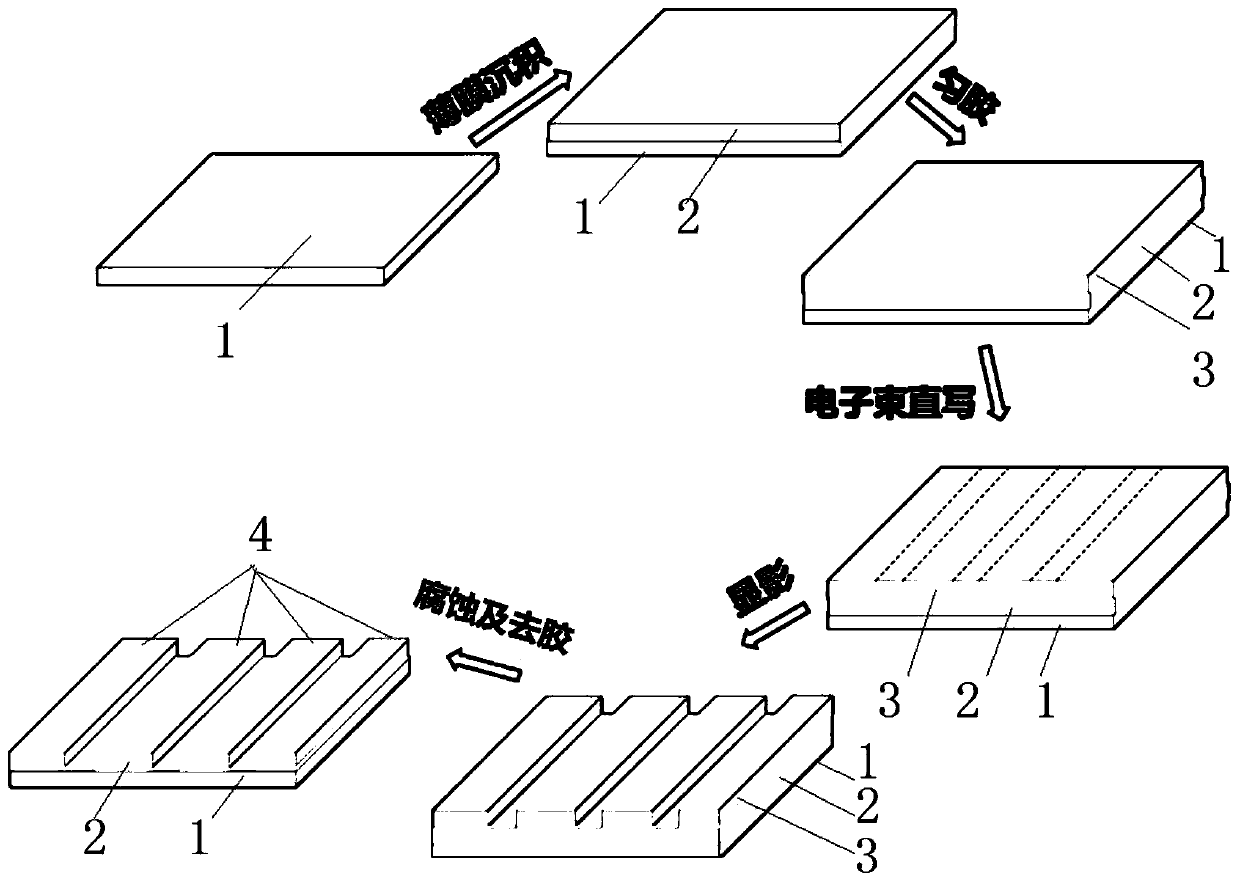

[0036] Such as figure 1 As shown, the preparation method of the standard template for calibration of the nanometer measuring instrument of the present embodiment comprises the steps:

[0037] Step 1. Soak a 4-inch monocrystalline silicon wafer in acetone for 5 minutes and ultrasonically for 2 minutes, then perform the same operation in absolute ethanol to remove impurities on the surface of the monocrystalline silicon wafer, and then rinse it with deionized water. Put it into a vacuum drying oven for drying treatment.

[0038] Step 2, put the cleaned single crystal silicon wafer into the chamber of the atomic layer deposition equipment, and deposit a layer of Al on the surface of the single crystal silicon wafer by atomic layer deposition technology 2 o 3 Film 2 (i.e. to obtain said first structure), Al 2 o 3 The growth rate of film 2 is 0.1nm per cycle, by controlling the number of cycles, the Al 2 o 3 The thickness of the film can be precisely controlled at a certain h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com