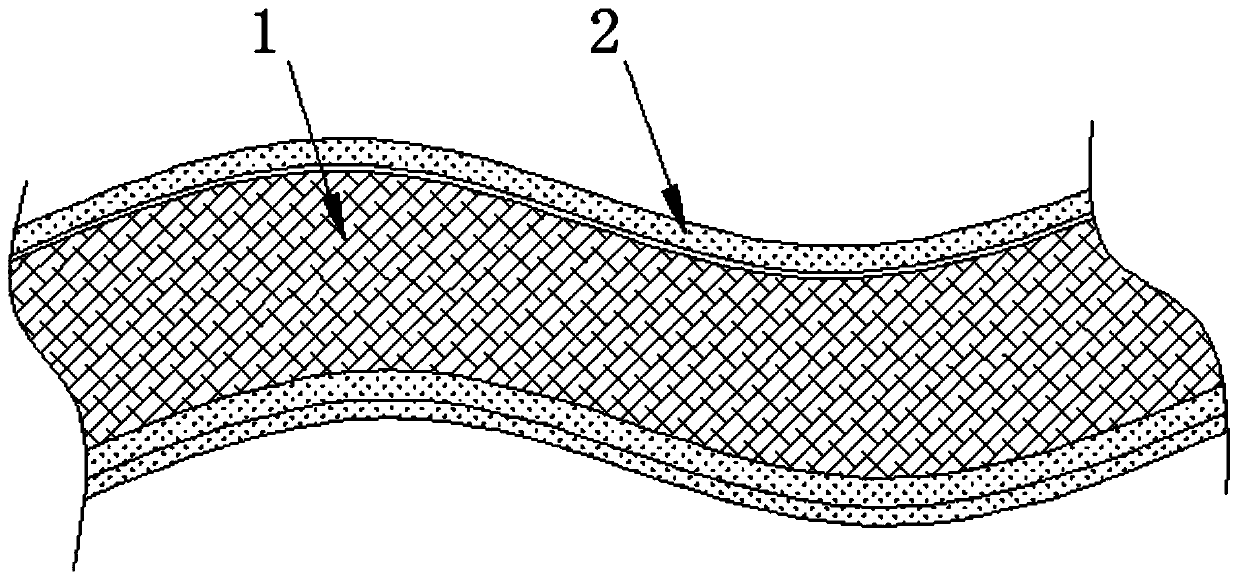

Novel sweat absorbing moisture exhausting elastic waist liner and production technology

A waist lining and elastic technology, applied in the field of textiles, can solve problems such as poor comfort, poor sweat absorption and moisture absorption, and easy pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

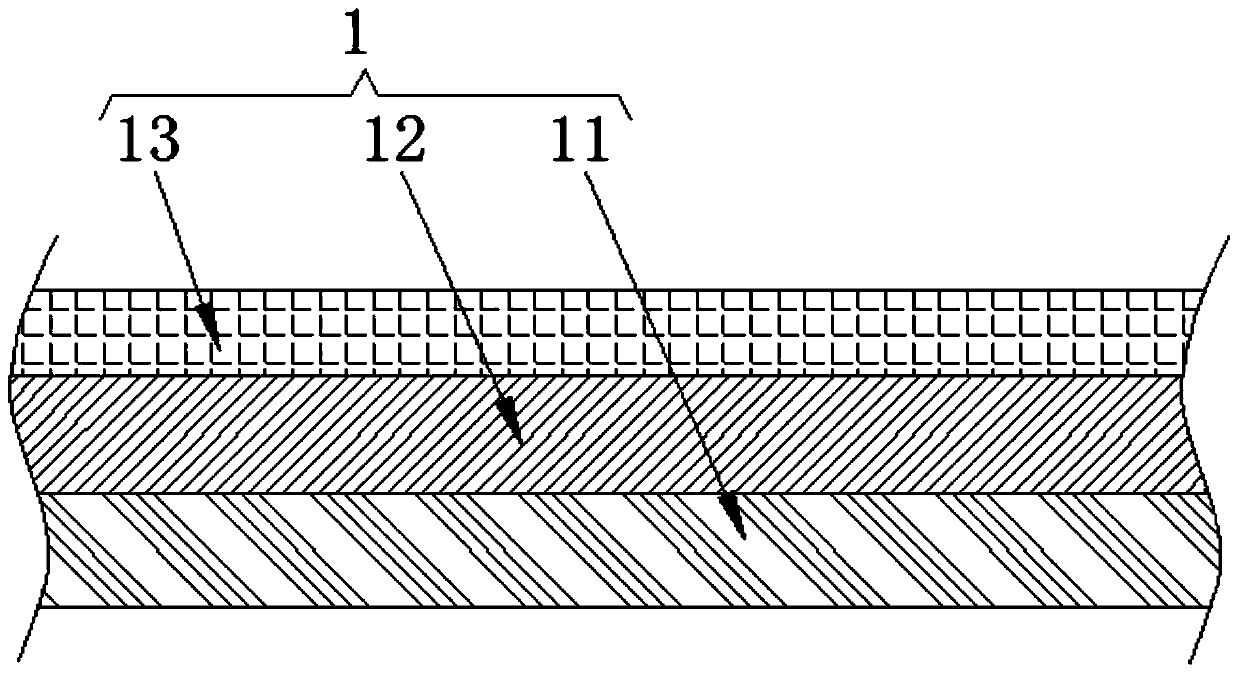

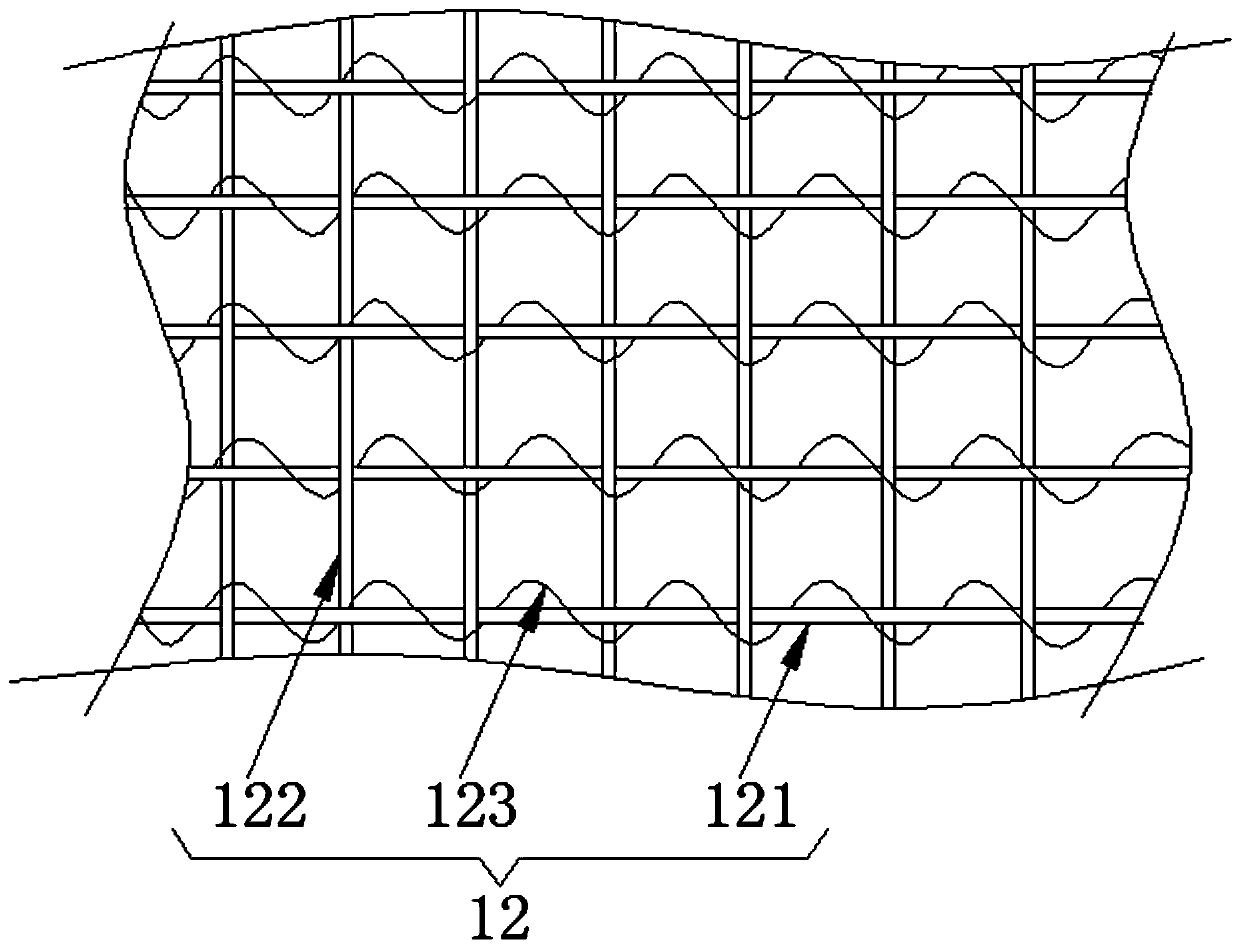

[0034] S1, 10 parts of elastic fibers, 20 parts of cellulose fibers, 10 parts of cotton fibers, 25 parts of polyester fibers, 23 parts of synthetic fibers and 32 parts of polypropylene fibers are stretched respectively to form elastic fiber filaments 121, cellulose Fiber filament 42, cotton fiber filament 123, polyester fiber filament 111, synthetic fiber filament 112 and polypropylene fiber filament 131;

[0035] S2. Winding the cotton fiber filaments 123 prepared in step S1 on the surface of the elastic fiber filaments 121, and cross-spun the elastic fiber filaments 121 and the cellulose fiber filaments 42 through a textile machine to make the inner layer 12;

[0036]S3, the polyester fiber yarn 111 and the elastic fiber yarn 121 prepared in the step S1 are cross-spun through a textile machine to make the outer layer 11, and then the outer layer 11 and the inner layer 12 prepared in the step S2 are hot-rolled Bonding to obtain the base cloth layer, the temperature of the hot...

Embodiment 2

[0040] S1, 15 parts of elastic fibers, 25 parts of cellulose fibers, 15 parts of cotton fibers, 30 parts of polyester fibers, 26 parts of synthetic fibers and 39 parts of polypropylene fibers are stretched respectively to form elastic fiber filaments 121, cellulose Fiber filament 42, cotton fiber filament 123, polyester fiber filament 111, synthetic fiber filament 112 and polypropylene fiber filament 131;

[0041] S2. Winding the cotton fiber filaments 123 prepared in step S1 on the surface of the elastic fiber filaments 121, and cross-spun the elastic fiber filaments 121 and the cellulose fiber filaments 42 through a textile machine to make the inner layer 12;

[0042] S3, the polyester fiber yarn 111 and the elastic fiber yarn 121 prepared in the step S1 are cross-spun through a textile machine to make the outer layer 11, and then the outer layer 11 and the inner layer 12 prepared in the step S2 are hot-rolled Bonding to obtain the base cloth layer, the temperature of the ho...

Embodiment 3

[0046] S1, 20 parts of elastic fibers, 30 parts of cellulose fibers, 20 parts of cotton fibers, 35 parts of polyester fibers, 30 parts of synthetic fibers and 45 parts of polypropylene fibers are stretched respectively to form elastic fiber filaments 121, cellulose Fiber filament 42, cotton fiber filament 123, polyester fiber filament 111, synthetic fiber filament 112 and polypropylene fiber filament 131;

[0047] S2. Winding the cotton fiber filaments 123 prepared in step S1 on the surface of the elastic fiber filaments 121, and cross-spun the elastic fiber filaments 121 and the cellulose fiber filaments 42 through a textile machine to make the inner layer 12;

[0048] S3, the polyester fiber yarn 111 and the elastic fiber yarn 121 prepared in the step S1 are cross-spun through a textile machine to make the outer layer 11, and then the outer layer 11 and the inner layer 12 prepared in the step S2 are hot-rolled Bonding to obtain the base cloth layer, the temperature of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com