A kind of artificial capsular multifunctional particle and its preparation method and application

A multifunctional, capsular technology, applied in chemical instruments and methods, polluted waterways/lakes/ponds/rivers treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as limited scope of use, to prevent bottom The effects of mud floating, high mechanical strength, and strong impact load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

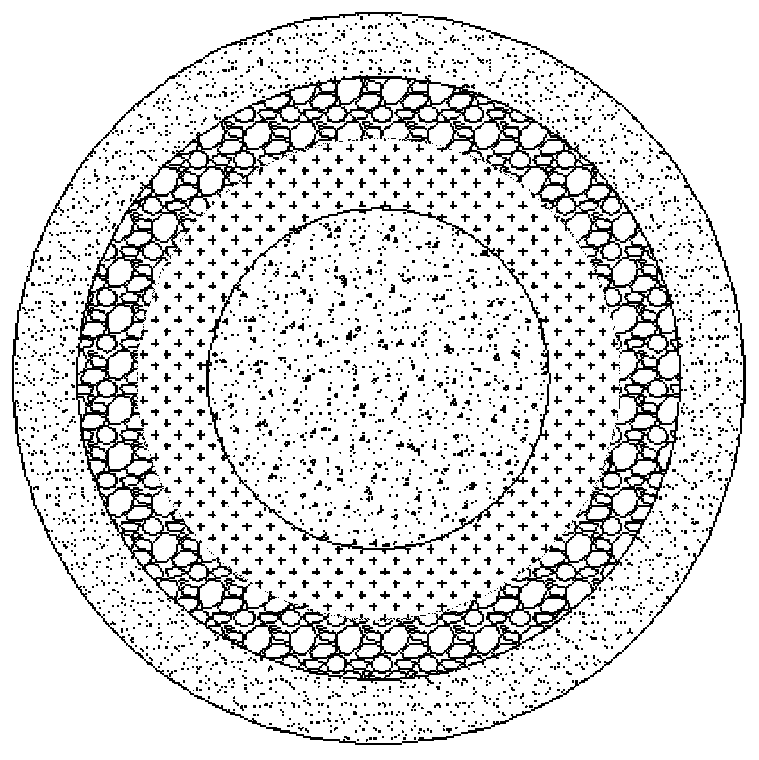

[0029] The invention provides a method for preparing "artificial capsule" type multifunctional particles, comprising the following steps:

[0030] 1) mixing the pulverized ore, the first binder, the first flocculant, microorganisms and water, and then successively granulating and drying to obtain ore particles;

[0031] 2) After mixing the mineral particles, the second binder and water, then adding the second flocculant to obtain mineral particles-bonding-flocculation structure particles;

[0032] 3) The mineral particle-bonding-flocculation structure particle is mixed with highly efficient degrading bacteria to obtain "artificial capsule" type multifunctional particles.

[0033] In the invention, the crushed ore, the first binder, the first flocculant, microorganisms and water are mixed, and then successively granulated and dried to obtain ore particles. In the present invention, the ore is preferably crushed and sieved to a size of ≤0.85 mm, more preferably 0.4 mm to 0.85 m...

Embodiment 1

[0049] Grind and sieve the zeolite with a particle size of 0.5mm. Weigh 200g of the crushed zeolite, 1.6g of chitosan, 1g of PAC, 0.6g of microbial powder, and 8mL of water. After mixing evenly, granulate, dry, and dry The temperature is 60°C, and spherical ore particles with a diameter of 2mm are obtained.

[0050] Weigh 200g of spherical mineral particles, 10g of chitosan and 4mL of water and mix them thoroughly to make a layer of chitosan adhere to the surface of the mineral particles, then add 14g of PAC, and fully stir and mix to obtain mineral particles-bonding-flocculation structure particles.

[0051] Weigh 1 g of photosynthetic bacteria, 200 g of mineral particle-bonding-flocculation structure particles, and stir evenly to obtain "artificial capsule" type multifunctional particles.

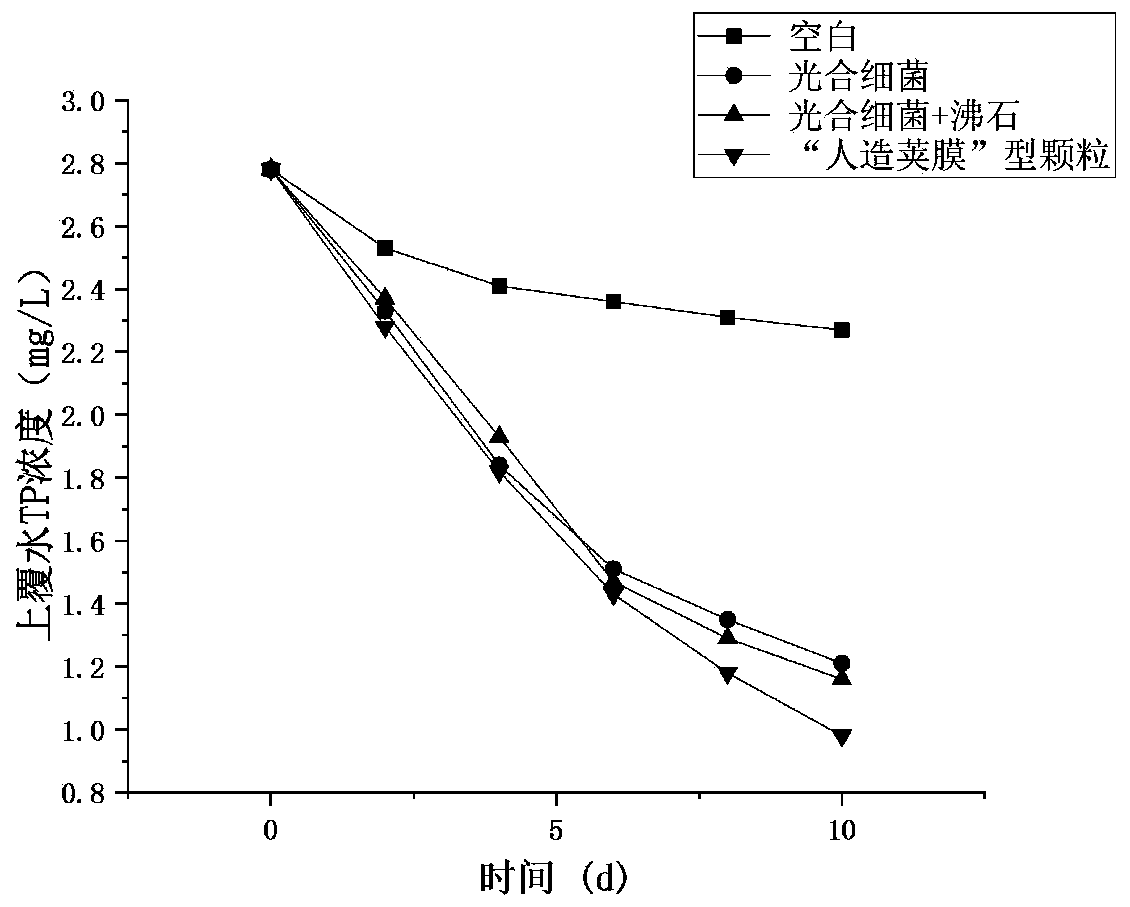

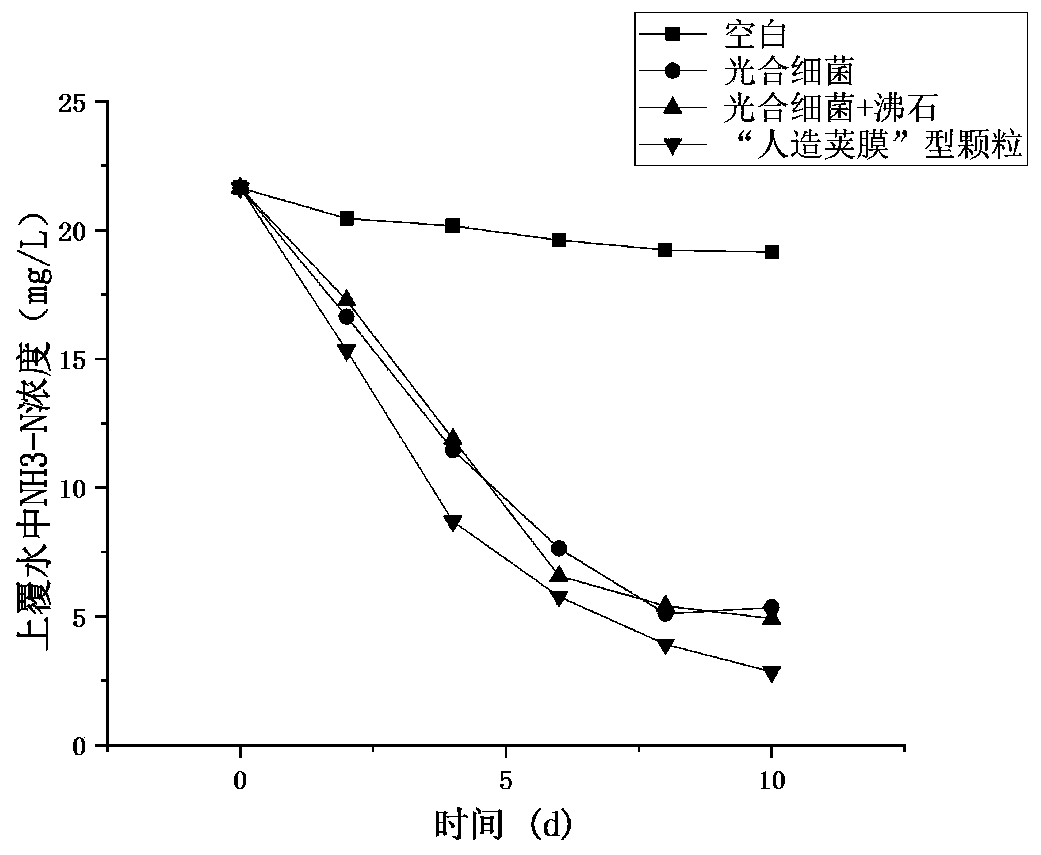

[0052] Add 200g of "artificial capsule" multifunctional granules into 1L of river water. After the granules are put into the river, aeration and oxygenation are needed to increase the riv...

Embodiment 2

[0077] The medical stone and zeolite were crushed and sieved respectively, the particle size was 0.5 mm, and 40 parts of the crushed medical stone, 35 parts of zeolite, 0.8 part of chitosan, 0.5 part of PAC, 0.3 part of microorganism and 6 parts of water were weighed. After stirring and mixing evenly, granulation and drying are carried out in sequence. The drying temperature is 55° C. to obtain spherical mineral particles with a diameter of 3 mm.

[0078]Weigh 85 parts of mineral particles, 5 parts of chitosan and 4 parts of water, fully stir and mix, so that a layer of chitosan is attached to the surface of the mineral particles, and then add 7 parts of PAC, fully stir and mix to obtain mineral particles-bonding-flocculation Structural particles.

[0079] Weigh 0.5 parts of photosynthetic bacteria and 85 parts of mineral particles-bonding-flocculation structure particles, and stir evenly to obtain "artificial capsule" type multifunctional particles. The purification effect o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com