Modified hydroxypropyl methyl cellulose ether dry powder material

A technology of hydroxypropyl methylcellulose and hydroxypropyl starch ether, which is applied in the field of modified hydroxypropyl methylcellulose ether dry powder, can solve the problems of poor water retention rate of mortar, pulverization of mortar surface, and poor strength , to achieve the effect of high early strength, high water retention rate, and no chalking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A modified hydroxypropyl methylcellulose ether dry material comprises the following components:

[0021] 865kg of hydroxypropyl methylcellulose ether, 67kg of polyvinyl alcohol, 20kg of anionic polyacrylamide, 19kg of white carbon black, 15kg of polycarboxylate superplasticizer, and 14kg of hydroxypropyl starch ether.

[0022] Put all the materials into a V-shaped three-dimensional mixer, and after fully stirring for 90 minutes, take 3kg of modified hydroxypropyl methylcellulose ether dry material for later use.

[0023] Making standard dry powder mortar:

[0024] 42.5# ordinary Portland cement 350kg; 40-70 mesh quartz sand 615kg, 3-6mm polypropylene short fiber 2kg; redispersible latex powder 30kg, modified hydroxypropyl methyl cellulose ether dry material 3kg, put Put it into the mortar mixer and mix it fully for 30 minutes, and make it into a standard dry powder mortar, that is, dry powder mortar for external wall insulation and plastering.

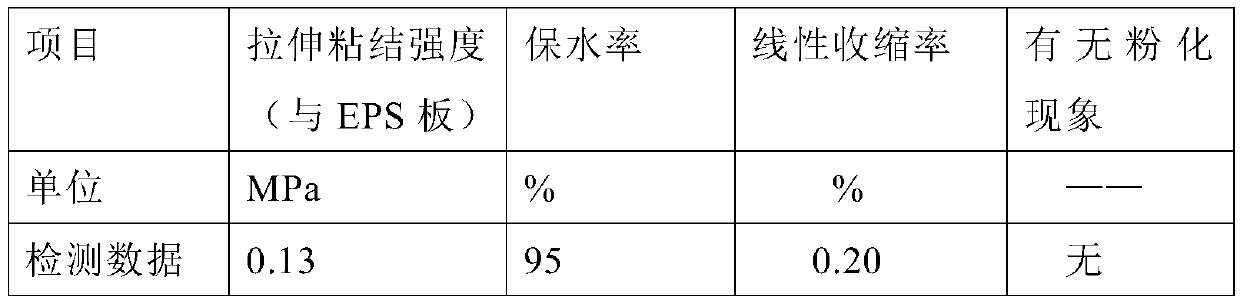

[0025] Add 210-230kg o...

Embodiment 2

[0029] A modified hydroxypropyl methylcellulose ether dry material should include the following components:

[0030] 875kg of hydroxypropyl methylcellulose ether, 65kg of polyvinyl alcohol, 17kg of anionic polyacrylamide, 18kg of white carbon black, 12kg of polycarboxylate superplasticizer, and 13kg of hydroxypropyl starch ether.

[0031] Put all the materials into a V-shaped three-dimensional mixer, and after fully stirring for 90 minutes, take 3kg of modified hydroxypropyl methylcellulose ether dry material for later use.

[0032] Making standard dry powder mortar:

[0033] 42.5# ordinary Portland cement 350kg; 40-70 mesh quartz sand 615kg, 3-6mm polypropylene short fiber 2kg; redispersible latex powder 30kg, modified hydroxypropyl methyl cellulose ether dry material 3kg, put Put it into the mortar mixer and mix it fully for 30 minutes, and make it into a standard dry powder mortar, that is, dry powder mortar for external wall insulation and plastering.

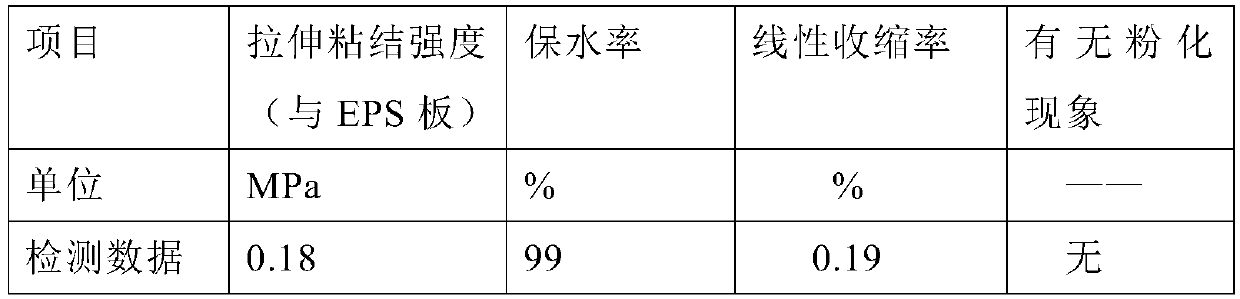

[0034] Add 210-23...

Embodiment 3

[0038] A modified hydroxypropyl methylcellulose ether dry material should include the following components:

[0039] 886kg of hydroxypropyl methylcellulose ether, 61kg of polyvinyl alcohol, 16kg of anionic polyacrylamide, 17kg of white carbon black, 10kg of polycarboxylate superplasticizer, and 10kg of hydroxypropyl starch ether.

[0040] Put all the materials into a V-shaped three-dimensional mixer, and after fully stirring for 90 minutes, take 3kg of modified hydroxypropyl methylcellulose ether dry material for later use.

[0041] Making standard dry powder mortar:

[0042] 42.5# ordinary Portland cement 350kg; 40-70 mesh quartz sand 615kg, 3-6mm polypropylene short fiber 2kg; redispersible latex powder 30kg, modified hydroxypropyl methyl cellulose ether dry material 3kg, put Put it into the mortar mixer and mix it fully for 30 minutes, and make it into a standard dry powder mortar, that is, dry powder mortar for external wall insulation and plastering.

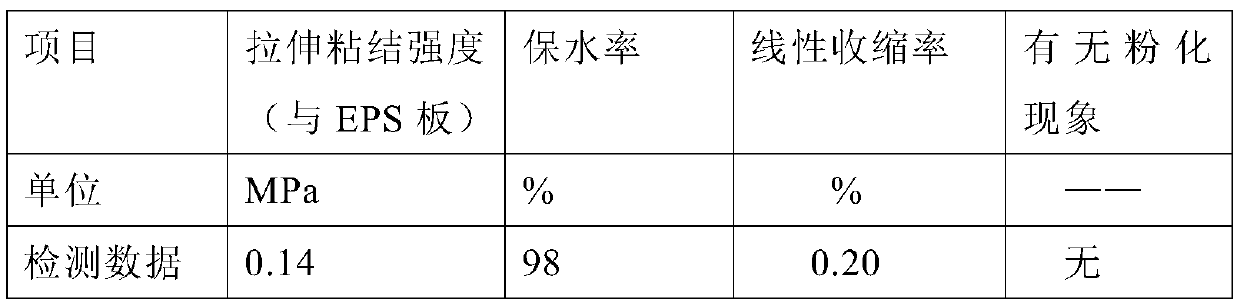

[0043] Add 210-23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com