Ionic crosslinking ultra-high molecular weight polyethylene material with self-repairing function and preparation method thereof

An ultra-high molecular weight, ion-crosslinking technology, applied in the field of ion-crosslinking ultra-high molecular weight polyethylene materials and preparation, to facilitate large-scale industrial production, expand application fields, and have excellent wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

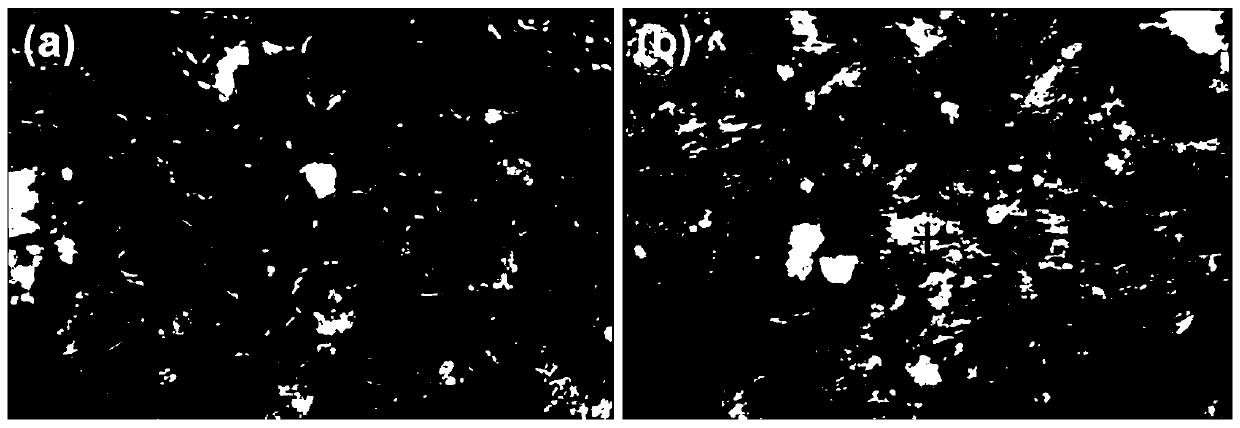

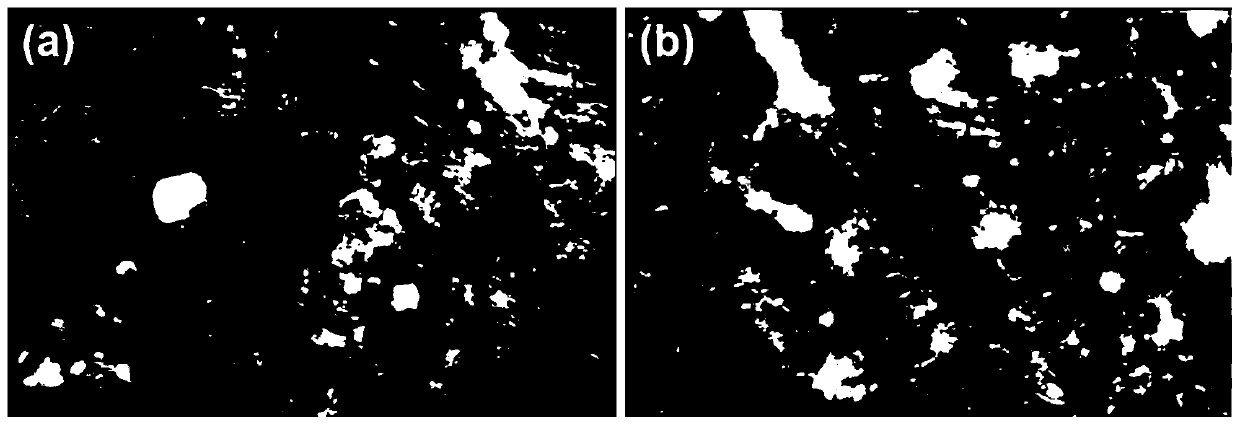

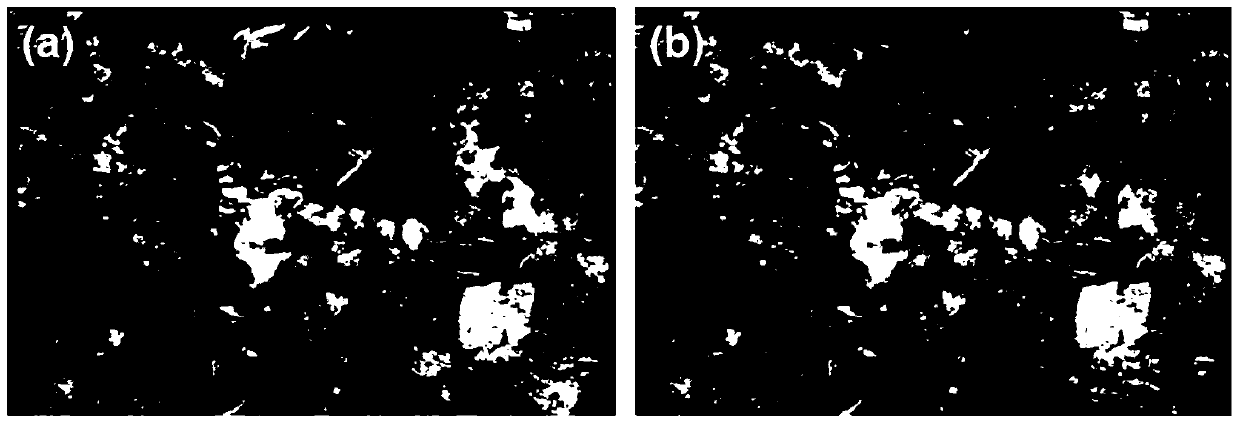

Image

Examples

Embodiment 1

[0033] An ionically cross-linked ultra-high molecular weight polyethylene material with self-healing function, the specific formula is: UHMWPE: 100Kg, high-density polyethylene: 12Kg, linear low-density polyethylene: 6Kg, zinc oxide: 2Kg Zinc stearate: 2Kg, dicumyl peroxide: 0.25Kg, acrylic acid: 3Kg, styrene: 1Kg.

[0034] The specific preparation process is as follows:

[0035] a Pre-dispersion: First, the molecular weight of 2.0 × 10 6 g / mol UHMWPE, high-density polyethylene, linear low-density polyethylene, zinc oxide and zinc stearate were placed in a high-speed mixer at 80 °C and mixed uniformly. Dicumyl peroxide, acrylic acid and styrene were dissolved in acetone and then misted. It is uniformly dispersed in UHMWPE / oxide / zinc stearate system;

[0036] b Reactive blending: The pre-dispersed samples are melt-reactively blended using a batch extensional rheological mixer, the temperature is 180°C, the time is 17min, and the rotation speed is 30rpm;

[0037] c Molding: T...

Embodiment 2

[0044] An ionically cross-linked ultra-high molecular weight polyethylene material with self-healing function, the specific formula is: UHMWPE: 100Kg, high-density polyethylene: 26Kg, linear low-density polyethylene: 15Kg, magnesium oxide: 9Kg, magnesium stearate : 6Kg, bis-2,5-dimethyl-2,5-bis(tert-butylperoxy)-hexane: 0.8Kg, methacrylic acid: 8Kg, styrene: 3.5Kg.

[0045] Its preparation process is as follows:

[0046] a Pre-dispersion: First, the molecular weight of 5.5 × 10 6g / mol UHMWPE, high-density polyethylene, linear low-density polyethylene, magnesium oxide and magnesium stearate were mixed uniformly in a high-speed mixer at 80 °C, and the bis-2,5-dimethyl-2,5-bis(tert- Butyl peroxy)-hexane, methacrylic acid and styrene are dissolved in tetrahydrofuran, atomized and uniformly dispersed in UHMWPE / oxide / magnesium stearate system;

[0047] b Reactive blending: The pre-dispersed samples are melt-reactively blended using a batch extensional rheological mixer, the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com