High-flexibility water-based varnish with good heat resistance and suitable for UV offset printing

A heat-resistant and flexible technology, applied in the field of high-flexibility water-based varnishes, it can solve problems such as restricting the application of water-based varnishes, scrapped prints, and UV ink bursting, and achieve excellent interlayer adhesion, good adhesion, and low VOC emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific embodiments:

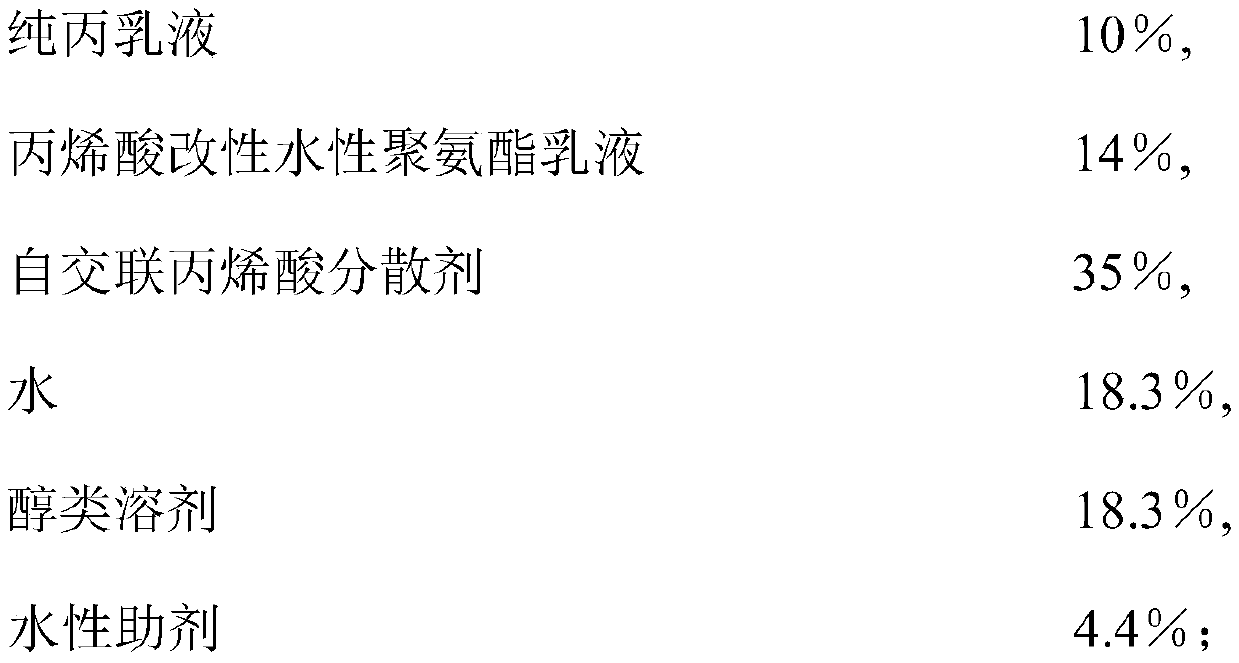

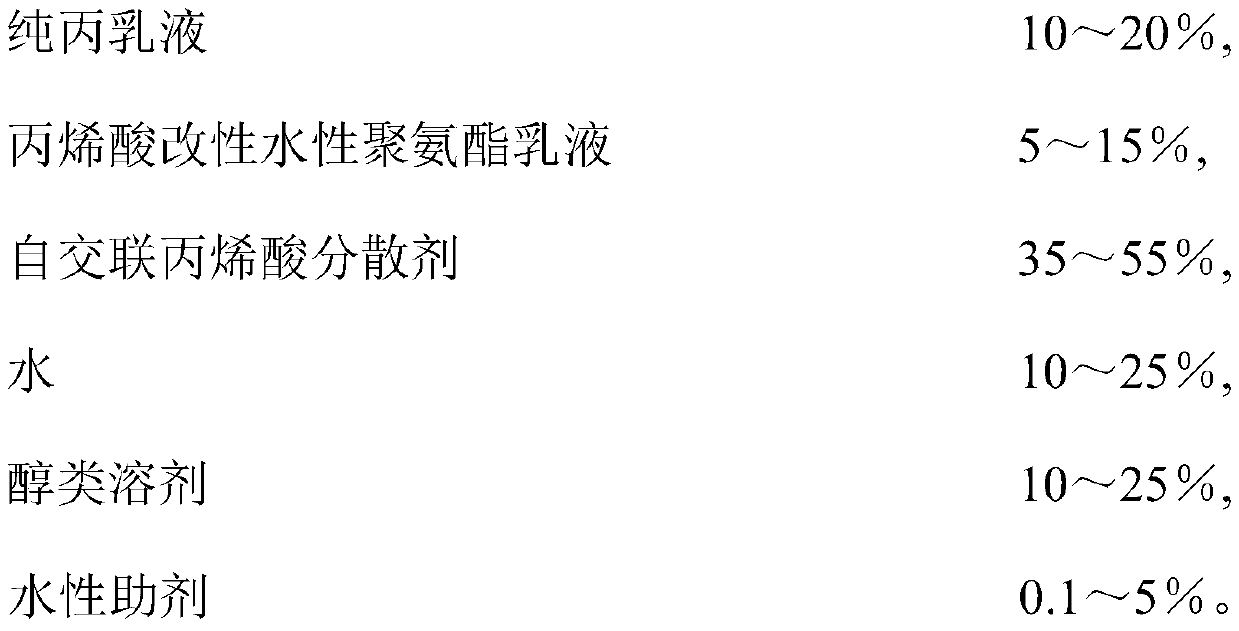

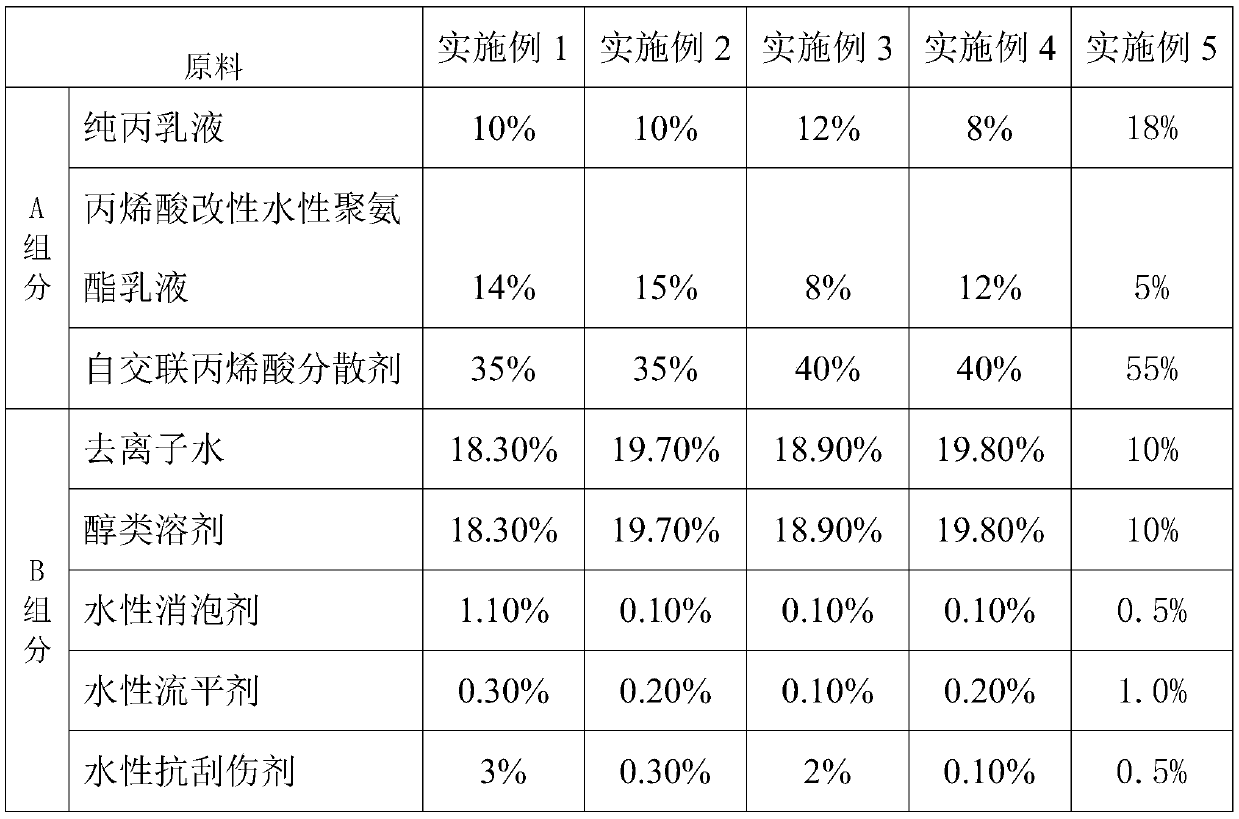

[0030] The composition of each component of Examples 1 to 5 in weight percentage is shown in Table 1:

[0031] Table 1:

[0032]

[0033] The preparation methods of the highly flexible water-based varnishes of Examples 1 to 5:

[0034] 1) Configure component A: add pure acrylic emulsion, acrylic modified waterborne polyurethane emulsion, and self-crosslinking acrylic dispersant into the dispersion tank according to the formula ratio, and stir at 200 rpm for 15 minutes.

[0035] 2) Configure component B: add deionized water, alcohol solvents, and water-based additives to the mixing tank in proportions, and stir for 15 minutes at 300 rpm.

[0036] 3) Mixing: Pump the well-stirred component B into the dispersion tank, mix with component A, and stir for 15 minutes at 200 rpm.

[0037] 4) Filtering and purifying packaging: The impurities are removed by filtering equipment to obtain a highly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com