Method for extracting coal tunnel stripe coal bed gas based on controllable shock waves

A technology for coal seam gas and shock wave, which is applied in the field of coal seam gas drainage in coal road strips, can solve the problems of high density of through-layer drilling holes, small effective drainage radius of drainage holes, poor drainage effect, etc. The effect of mining time, improving the economic benefit of coal mine and reducing the amount of drilling works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

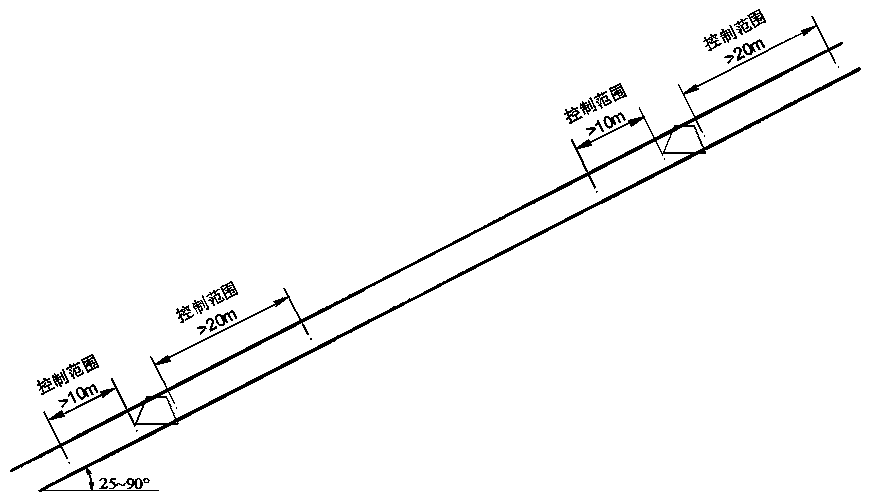

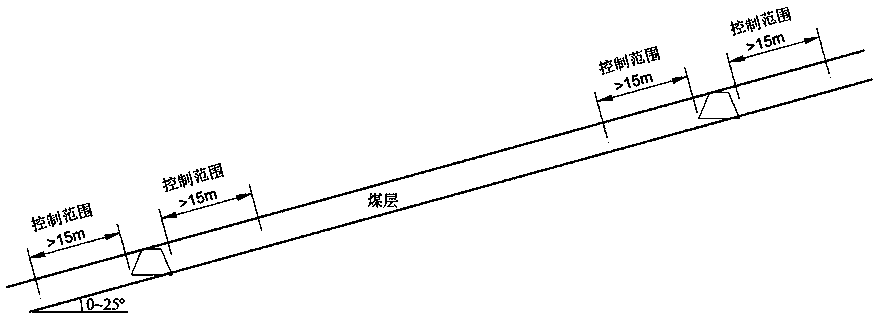

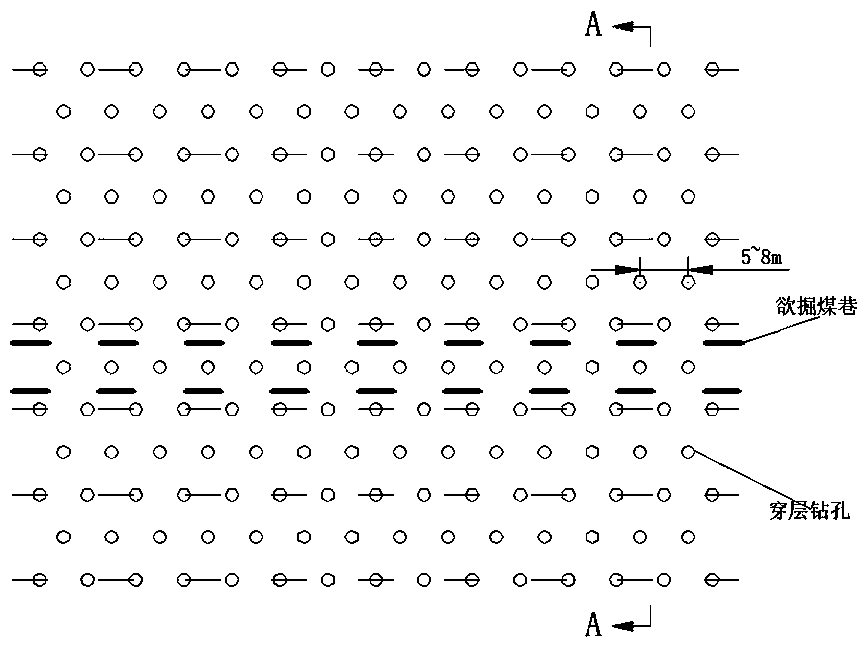

[0032] as attached Figures 5 to 9 As shown, a coal roadway strip coal seam gas drainage method based on controllable shock waves includes the following steps: the first step is to determine the technical parameters of the controllable shock wave anti-reflection technology in the geological unit where the controllable shock wave anti-reflection is to be implemented;

[0033] In the second step, the shock wave anti-reflection drilling 2 is constructed on the coal seam or the coal seam floor 4 and the roof 5 in the coal seam or coal seam floor 4 and roof 5 of the corresponding roof or floor drainage roadway 6 of the coal roadway to be excavated;

[0034] In the third step, after the construction of the shock wave anti-reflection drilling is completed, the drilling is washed, and the cinder or rock slag in the drilling is discharged;

[0035] The fourth step is to run the casing into the drill hole after cleaning the drill hole and fix the hole;

[0036] The fifth step is to low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com