Brush-type online cleaning system device

A cleaning system and brush-type technology, which is applied in the field of brush-type online cleaning system devices, can solve the problems of rubber balls easily blocking copper pipes, time-consuming and labor-intensive refrigeration systems, and stop running, so as to improve heat exchange efficiency and low operating costs , Easy replacement of brushes

Inactive Publication Date: 2020-01-07

威吽(深圳)科技有限公司

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] 1. Manual poking cleaning: It is to use manual methods, such as iron rods, electric brushes, etc., to insert into the copper tubes of the condenser to perform mechanical descaling one by one. The end cover needs to be removed, and the end cover should be replaced after descaling and cleaning, which is time-consuming and labor-intensive, and the refrigeration system must be stopped

[0004] 2. Chemical agent cleaning: it is to add chemical agents to the cooling water in the copper tube of the condenser to suppress suspended solids and sediments to achieve the purpose of descaling, but this method has the following disadvantages, the amount of additives is difficult to control; Pollution to the environment; chemical corrosion to the copper tube of the condenser; if the descaling is not complete, the cover must be opened and cleaned manually regularly;

[0005] 3. Rubber cotton ball cleaning: This is to add a set of devices next to the condenser, including a ball machine, a recovery machine, a ball circulation pump, etc., using many rubber balls to rush into the copper tube of the condenser with water pressure, and clean the copper tube of the condenser. The solution of cleaning the inner wall to a certain extent has the following disadvantages: the copper pipes are cleaned randomly, and some copper pipes have never been cleaned; rubber balls are easy to block the copper pipes; the cleaning cycle is very long; the maintenance cost is very high. All rubber balls need to be replaced

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0023] Embodiment 2: On the basis of Embodiment 1, a three-way valve 2 is provided on the main pipeline 5 between the water flow reversing valve 8 and the secondary water return port 14 . A three-way valve 2 is provided on the main pipeline 5 between the water flow reversing valve 8 and the secondary water return port 14, and the dirt can be discharged through the drain valve.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

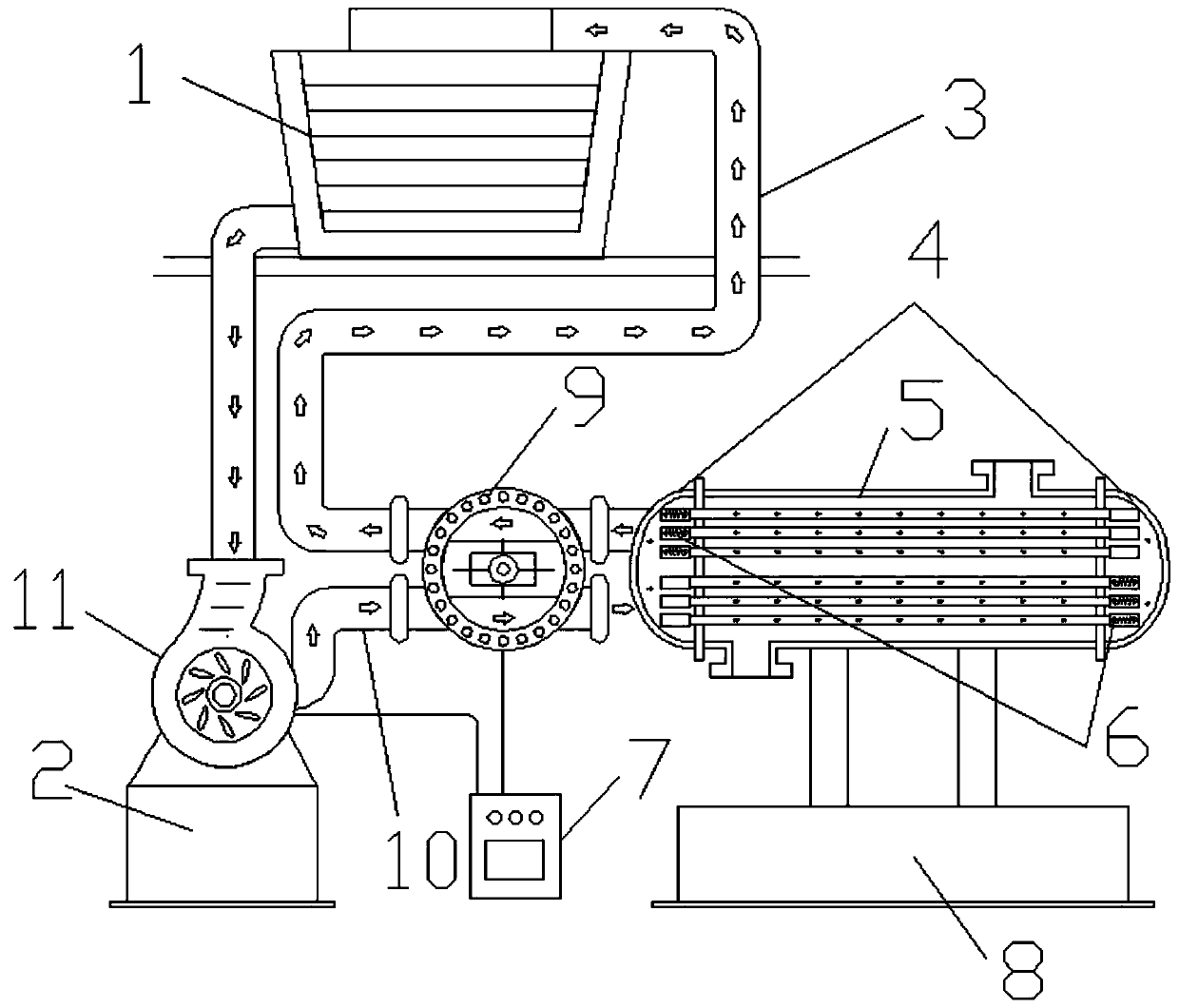

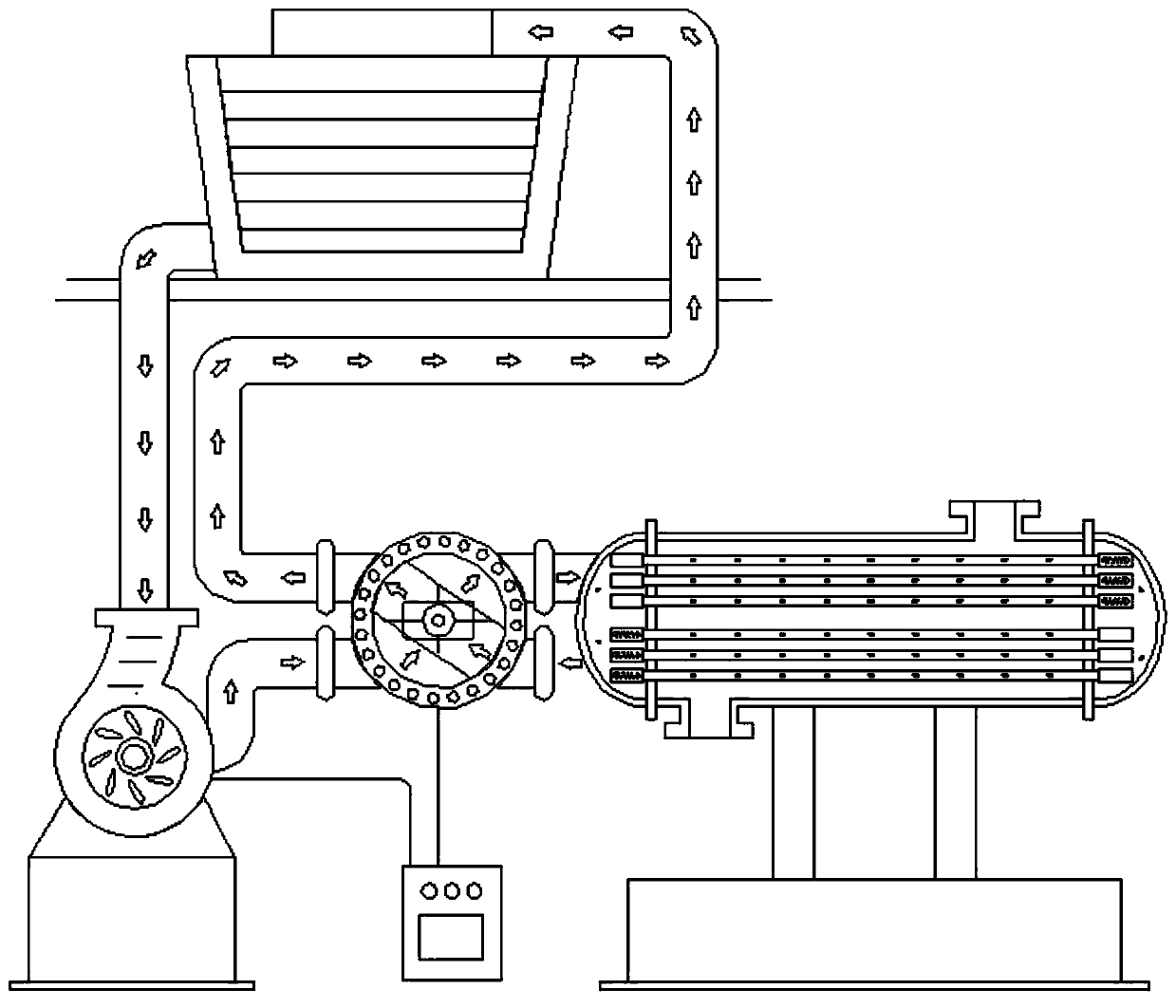

The invention discloses a brush-type online cleaning system device. The brush-type online cleaning system device comprises a cooling tower, a cooling water pump, a central air-conditioning main unit condenser, a four-way reversing valve and a four-way reversing valve controller. A water inlet of the cooling tower is connected with the four-way reversing valve through a water return pipe, a water outlet of the cooling tower is connected with the cooling water pump, an outlet of the cooling water pump is connected with the four-way reversing valve through a water inlet pipe, and the other two connectors of the cooling water pump are connected with a water inlet and a water outlet of the central air-conditioning main unit condenser respectively. The brush-type online cleaning system device has the advantages that a snap joint design is adopted for brush baskets, thus a brush is convenient to replace, and the brush-type online cleaning system device is applicable to light pipes and efficient threaded pipes; the service life is long since the pipe brush is made from a special material, on the condition that the pipe brush is continuously operated for 24 hours under a standard refrigerator working condition, the service life of the pipe brush is 5 years, and there is no need to replace the pipe brush within 5 years.

Description

technical field [0001] The invention relates to a heat exchange group, in particular to a brush type online cleaning system device. Background technique [0002] The copper tubes used for cleaning condensers are mainly divided into three categories: [0003] 1. Manual poking cleaning: It is to use manual methods, such as iron rods, electric brushes, etc., to insert into the copper tubes of the condenser to perform mechanical descaling one by one. The end cover needs to be removed, and then the end cover should be replaced after descaling and cleaning, which is time-consuming and laborious, and the refrigeration system must be stopped. [0004] 2. Chemical agent cleaning: it is to add chemical agents to the cooling water in the copper tube of the condenser to suppress suspended solids and sediments to achieve the purpose of descaling, but this method has the following disadvantages, the amount of additives is difficult to control; Pollution to the environment; chemical corr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F28G1/02F28G15/00

CPCF28G1/02F28G15/00

Inventor 芮荣军乐进

Owner 威吽(深圳)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com