Power battery pack heat dissipation device with heat pipe device and heat dissipation method thereof

A technology for power battery packs and heat sinks, which is applied to secondary batteries, battery pack components, circuits, etc. It can solve problems such as increasing battery temperature inconsistency, shortening battery life, and large temperature gradients in battery packs to improve temperature. Uneven distribution, increase temperature consistency, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

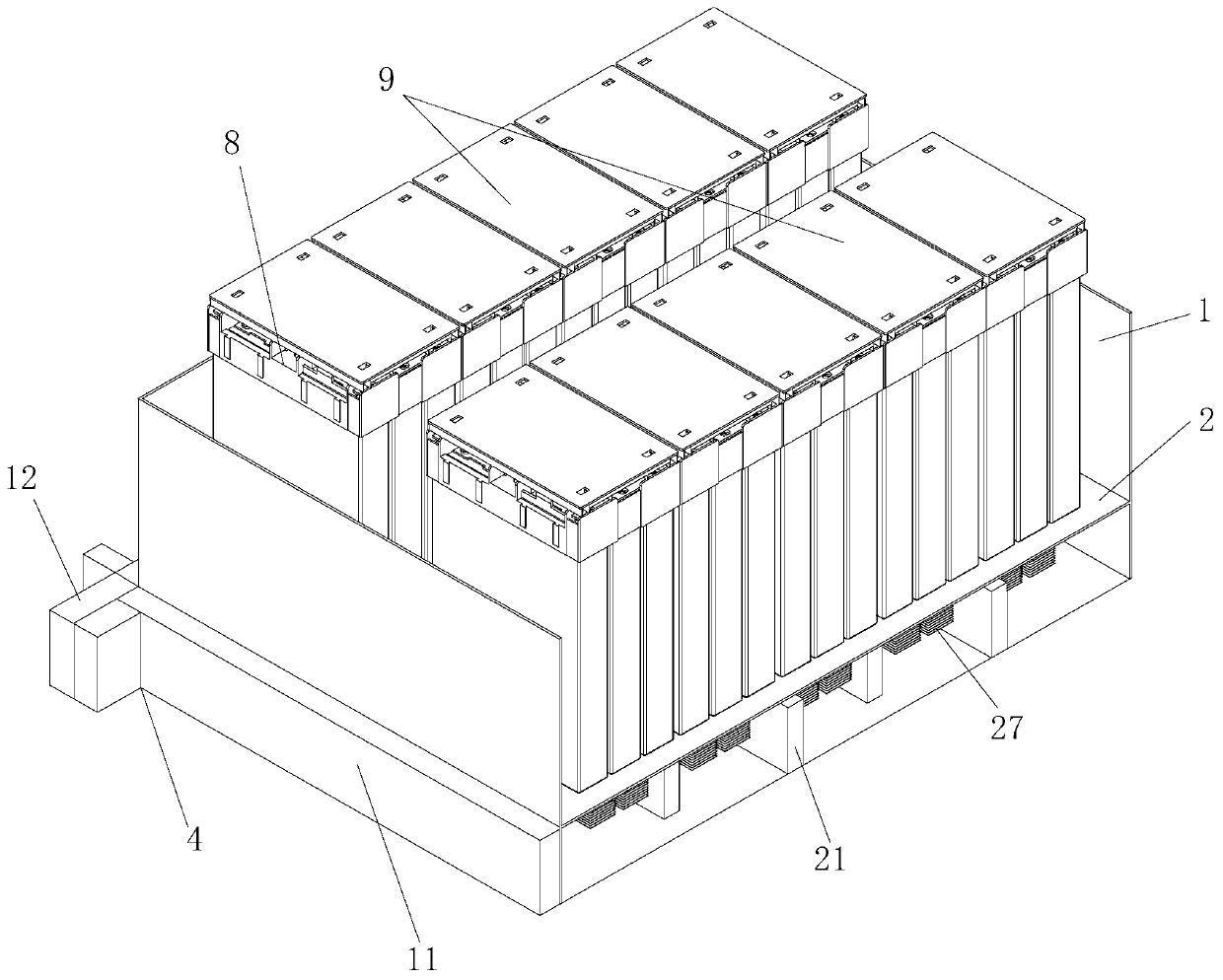

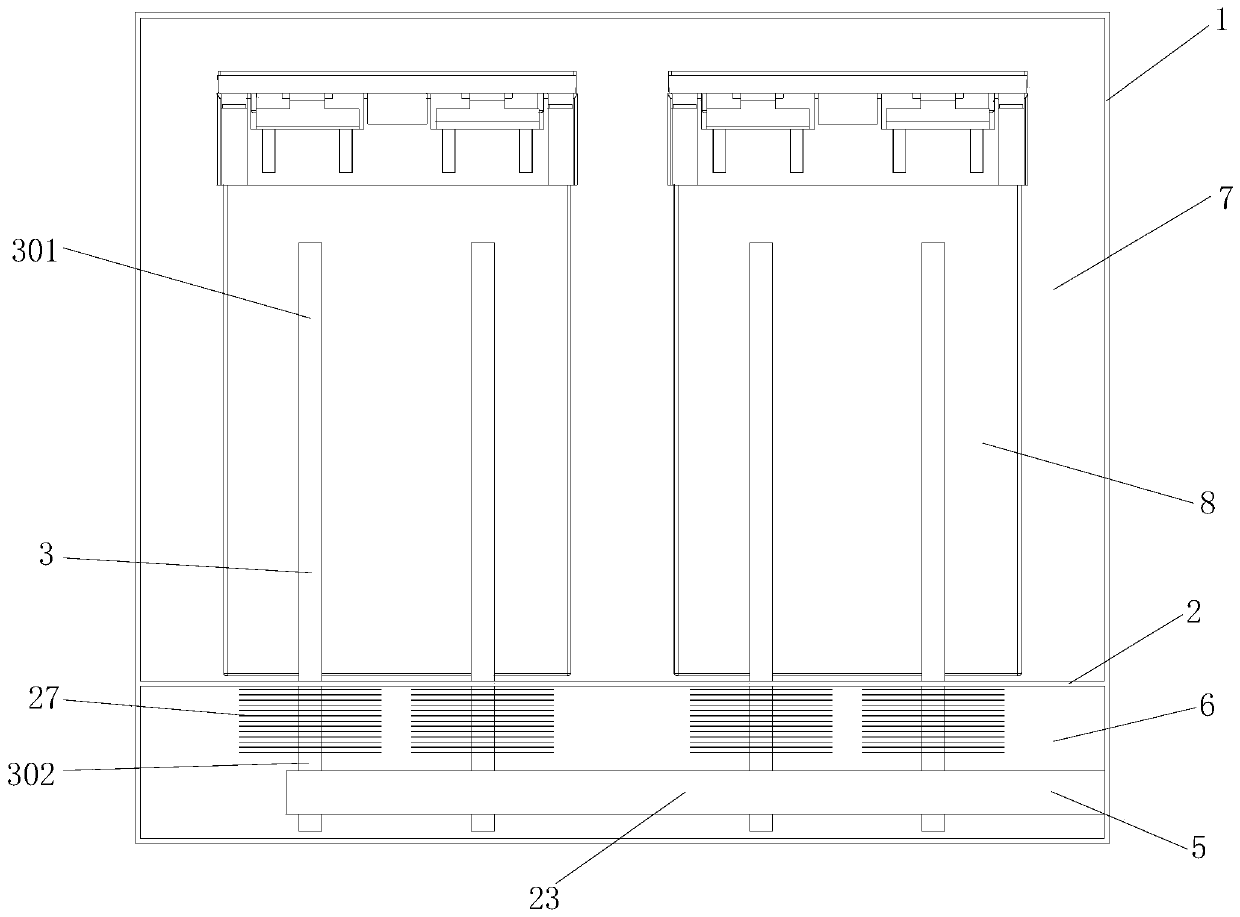

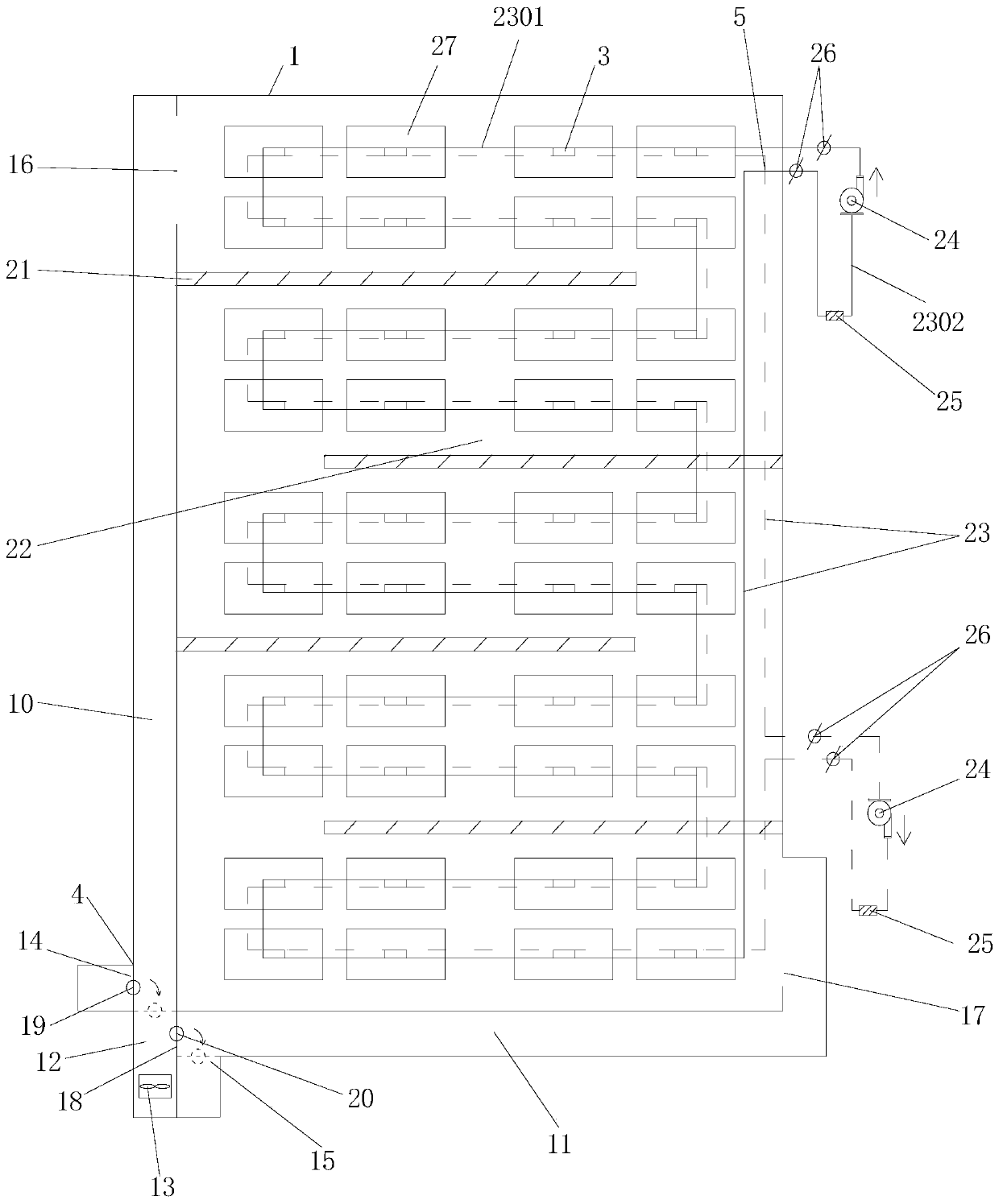

[0034] Such as Figure 1 to Figure 3 The heat dissipation device for the power battery pack shown with the heat pipe device includes a casing, a partition, a heat dissipation heat pipe, an air cooling mechanism, and a water cooling mechanism. cavity, the evaporating end of the heat dissipation heat pipe is closely attached to the electric core located in the heating cavity, the cooling end of the heat dissipation heat pipe passes through the partition and then extends into the heat dissipation cavity; the air cooling mechanism is installed on the outside of the shell, and the The heat dissipation air channel of the air cooling mechanism communicates with the heat dissipation cavity; the water cooling mechanism is connected with the cooling end of the heat dissipation heat pipe.

[0035] Specifically, such as figure 1 and figure 2 As shown, the partition divides the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com