Deep purification treatment method for wastewater and sewage

A technology of deep purification and treatment method, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. The effect of removing and improving adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for deep purification of waste water and sewage, which uses composite water quality treatment materials to carry out deep purification treatment of waste water or sewage. The specific process is: adding composite water quality treatment materials to waste water or sewage, stirring, static sedimentation, and centrifugal separation After that, the deep purification is completed;

[0029] The composite water quality treatment material is prepared by the following method:

[0030] S1 zeolite pretreatment: Stir the zeolite in hydrochloric acid solution, let it stand, and filter; boil the filtered zeolite in distilled water, wash it with distilled water, and finally put the zeolite in an oven to bake, and cool it for later use ;

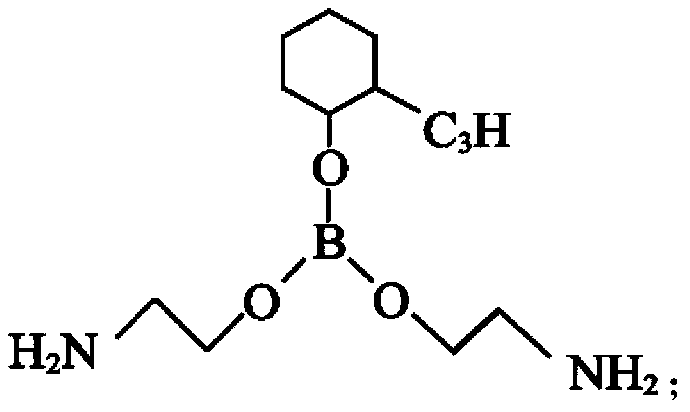

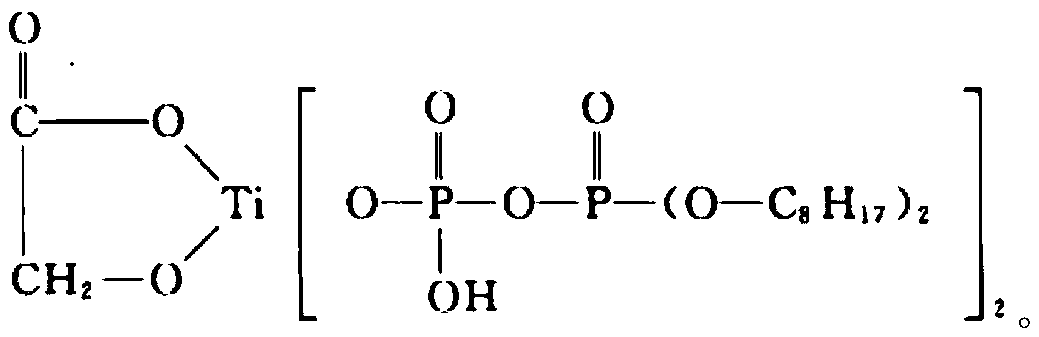

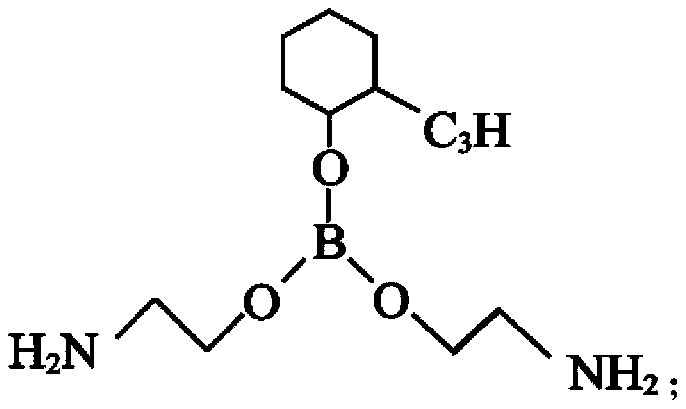

[0031] S2 Preparation of zeolite-supported nano-titanium dioxide: Add 10 g of pretreated zeolite and 5 g of coupling agent to 200 mL of titanium dioxide sol, filter out the sieve after ultrasonication and let it stand, dry it at a constant...

Embodiment 2

[0042] A method for deep purification of waste water and sewage, which uses composite water quality treatment materials to carry out deep purification treatment of waste water or sewage. The specific process is: adding composite water quality treatment materials to waste water or sewage, stirring, static sedimentation, and centrifugal separation After that, the deep purification is completed;

[0043] The composite water quality treatment material is prepared by the following method:

[0044] S1 zeolite pretreatment: Stir the zeolite in hydrochloric acid solution, let it stand, and filter; boil the filtered zeolite in distilled water, wash it with distilled water, and finally put the zeolite in an oven to bake, and cool it for later use ;

[0045] S2 Preparation of zeolite-supported nano-titanium dioxide: Add 10 g of pretreated zeolite and 5 g of coupling agent to 200 mL of titanium dioxide sol, filter out the sieve after ultrasonication and let it stand, dry it at a constant...

Embodiment 3

[0056] A method for deep purification of waste water and sewage, which uses composite water quality treatment materials to carry out deep purification treatment of waste water or sewage. The specific process is: adding composite water quality treatment materials to waste water or sewage, stirring, static sedimentation, and centrifugal separation After that, the deep purification is completed;

[0057] The composite water quality treatment material is prepared by the following method:

[0058] S1 zeolite pretreatment: Stir the zeolite in hydrochloric acid solution, let it stand, and filter; boil the filtered zeolite in distilled water, wash it with distilled water, and finally put the zeolite in an oven to bake, and cool it for later use ;

[0059] S2 Preparation of zeolite-supported nano-titanium dioxide: Add 10 g of pretreated zeolite and 5 g of coupling agent to 200 mL of titanium dioxide sol, filter out the sieve after ultrasonication and let it stand, dry it at a constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com