Packaging structure and making and packaging process for baked food

A food packaging and packaging structure technology, applied in the field of baked food packaging, can solve the problems of desiccant safety hazards, air-conditioning loss, unfavorable food safety, etc., and achieve the effects of saving cooling time and space, improving processing efficiency, and shortening processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

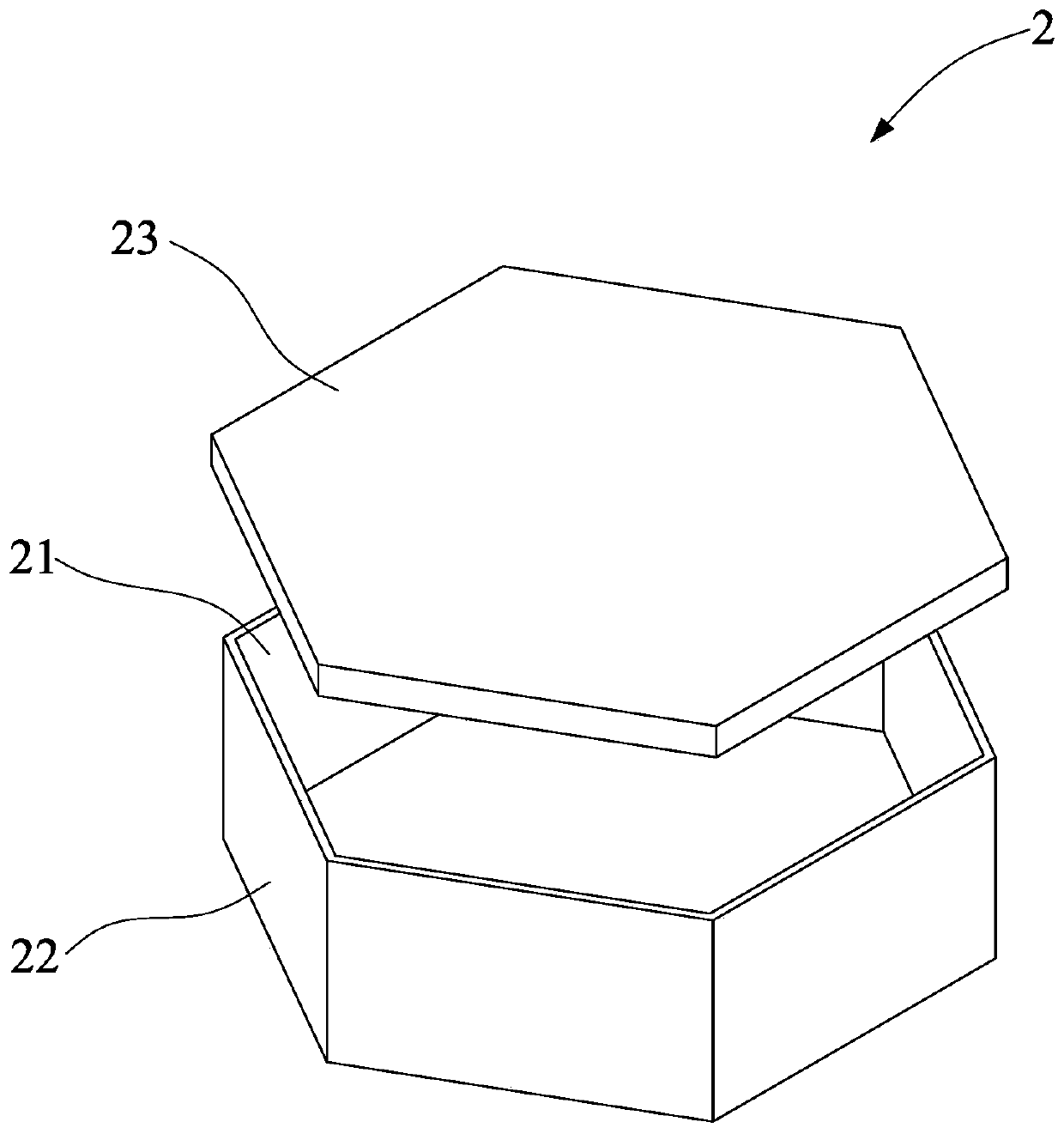

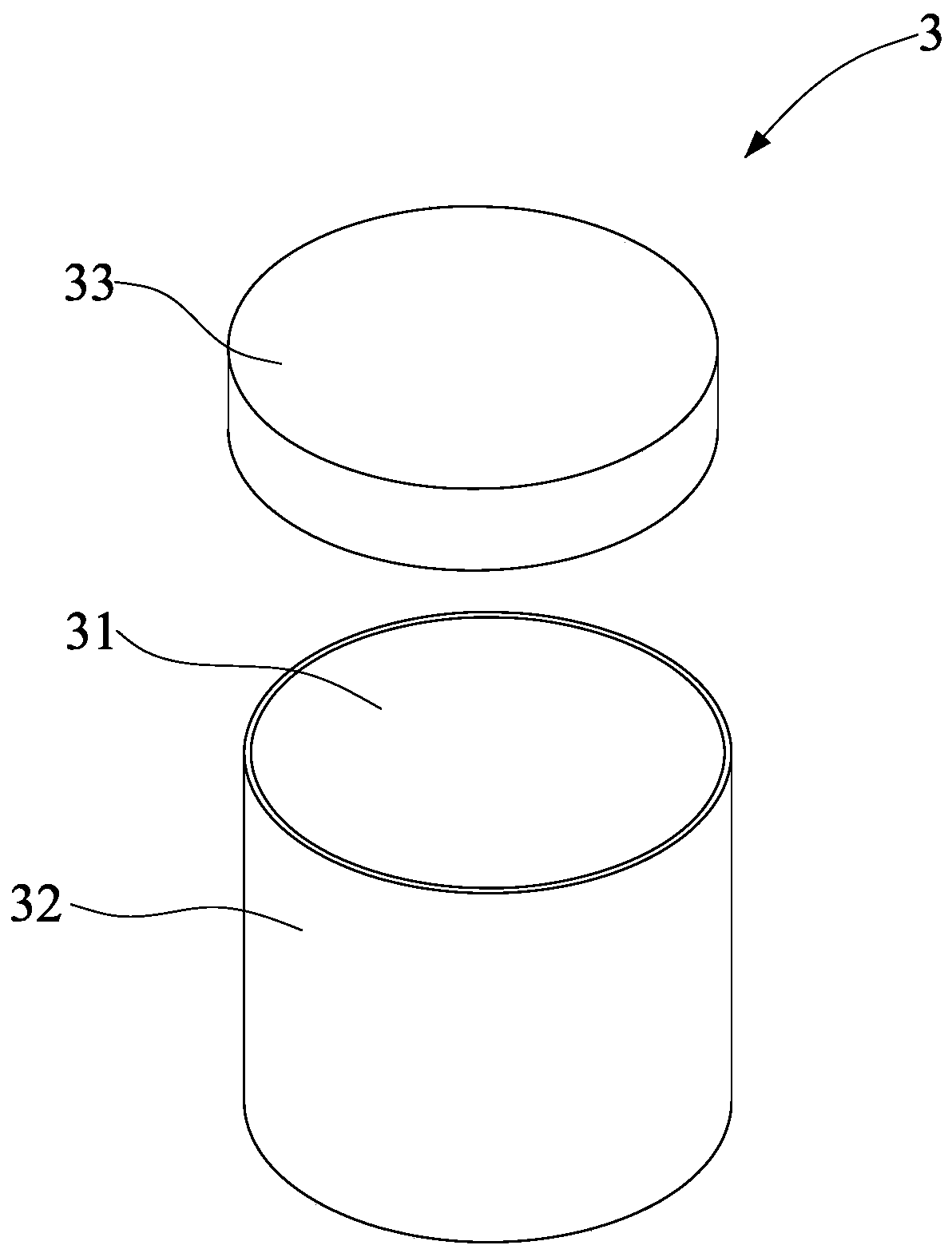

[0024] Such as Figure 1 to Figure 3 As shown, the present invention discloses a baked food packaging structure, which is mainly a flat sheet of high-density polyethylene special paper made by a flash method. The fiber strength is similar to that of commonly used chemical fibers, and exceeds most natural fibers. After being fixed into paper, the finished special paper has far more tensile strength and tear strength than cloth of the same thickness and ordinary paper.

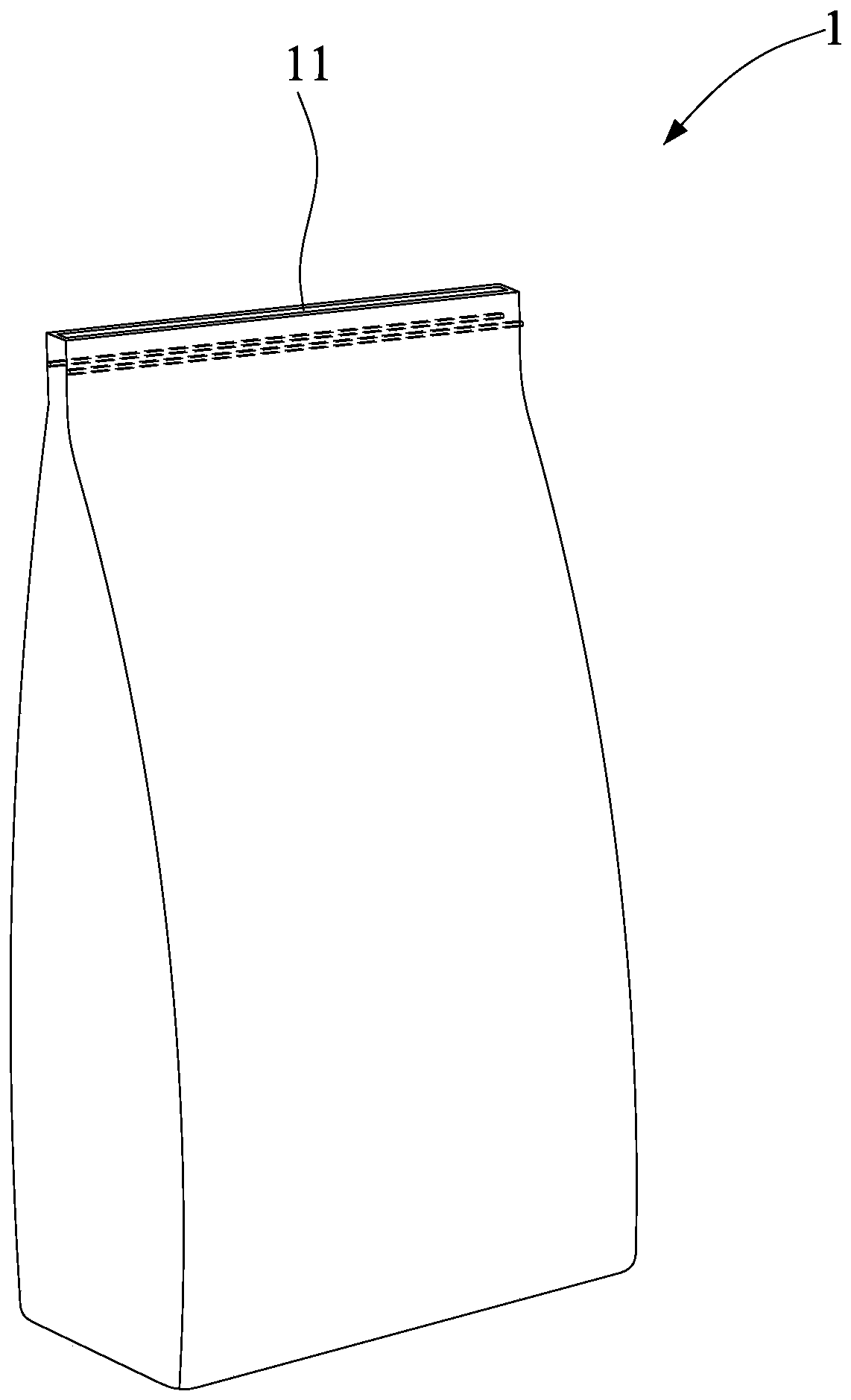

[0025] Such as figure 1 As shown, it is one of the embodiments of the packaging structure of the present invention. In this embodiment, the packaging structure is a packaging bag 1 with an opening 11, and the packaging bag 1 is made of a flat sheet of high-density polyethylene special paper made by a flash method. , the baked food can be loaded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com