Wastewater treatment device and method

A wastewater treatment and wastewater technology, applied in multi-stage water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex structure, high construction cost, poor oil absorption effect, etc. The effect of oil pollution content, expansion of water flow area, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

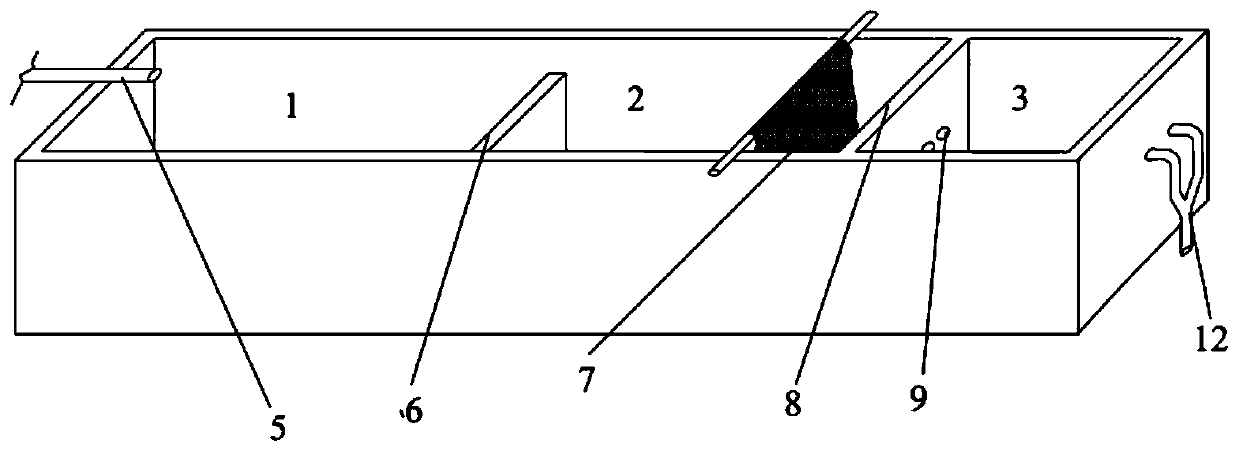

[0044] This embodiment provides a wastewater treatment device, its three-dimensional structure is shown in figure 1 , specifically including,

[0045] Water inlet 5, first sedimentation tank 1, second sedimentation tank 2, third sedimentation tank 3, first partition wall 6, oil absorbing device (this embodiment is oil-absorbing geotextile) 7, second partition wall 8, first channel The hole 9 and the water outlet 12, the water inlet is arranged on the top of the side wall of the first sedimentation tank, the water outlet is arranged on the side wall of the third sedimentation tank, and the first sedimentation tank and the second sedimentation tank are separated by the first partition wall , the second sedimentation tank and the third sedimentation tank are separated by the second partition wall, the second partition wall is provided with the first through hole, and the second sedimentation tank is provided with 2 oil-absorbing geotextiles, and the oil-absorbing geotextiles adop...

Embodiment 2

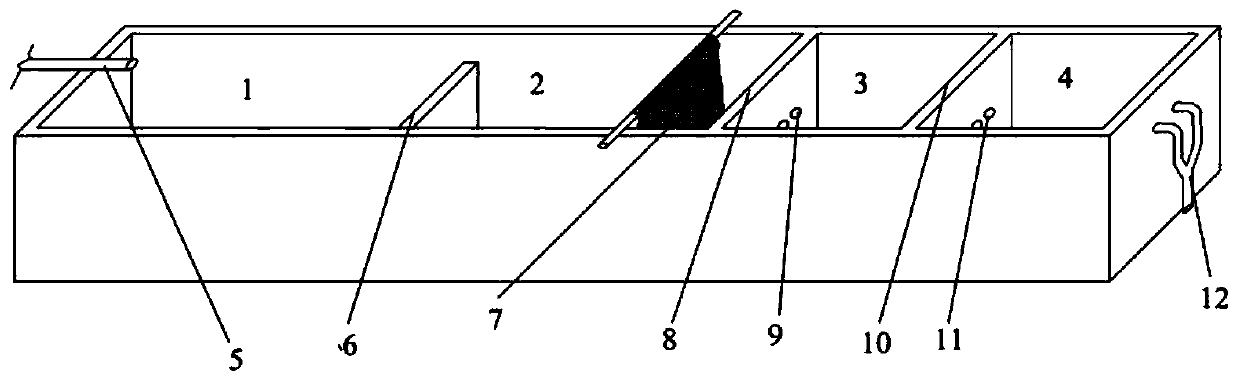

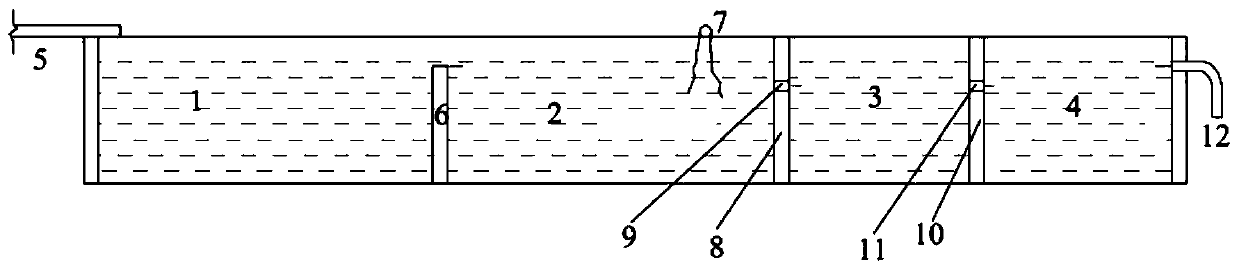

[0048] This embodiment provides a wastewater treatment device, its three-dimensional structure is shown in figure 2 , front view see image 3 , top view see Figure 4 , specifically including,

[0049] Water inlet 5, first sedimentation tank 1, second sedimentation tank 2, third sedimentation tank 3, fourth sedimentation tank 4, first partition wall 6, oil absorption device (this embodiment is oil absorption geotextile) 7, second partition Wall 8, the third partition wall 10, the first through hole 9, the second through hole 11 and the water outlet 12, the water inlet is arranged on the top of the side wall of the first sedimentation tank, the fourth sedimentation tank is connected in series with the third sedimentation tank, the second The third sedimentation tank and the fourth sedimentation tank are used to settle fine particles, the water outlet is set on the side wall of the fourth sedimentation tank, the first sedimentation tank and the second sedimentation tank are sep...

Embodiment 3

[0052] This embodiment provides a wastewater treatment device, which specifically includes:

[0053] Water inlet 5, first sedimentation tank 1, second sedimentation tank 2, third sedimentation tank 3, fourth sedimentation tank 4, first partition wall 6, oil absorption device (this embodiment is oil absorption geotextile) 7, second partition Wall 8, the third partition wall 10, the first through hole 9, the second through hole 11 and the water outlet 12, the water inlet is arranged on the top of the side wall of the first sedimentation tank, the fourth sedimentation tank is connected in series with the third sedimentation tank, the second The third sedimentation tank and the fourth sedimentation tank are used to settle fine particles, the water outlet is set on the side wall of the fourth sedimentation tank, the first sedimentation tank and the second sedimentation tank are separated by the first partition wall, the second sedimentation tank and the second sedimentation tank Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com