Special high-impermeability shrinkage-compensating concrete for urban underground comprehensive pipe galleries and preparation method thereof

A comprehensive pipe gallery and shrinkage compensation technology, which is applied in the field of concrete, can solve the problems affecting the anti-permeability and crack resistance of concrete, and the micro-cracks have no effect, so as to improve the impermeability and crack resistance, reduce the porosity, and improve the compactness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

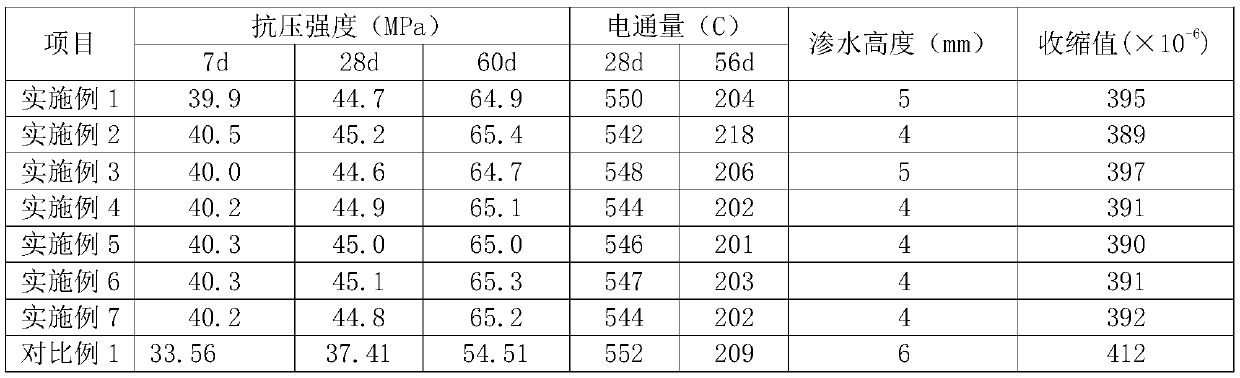

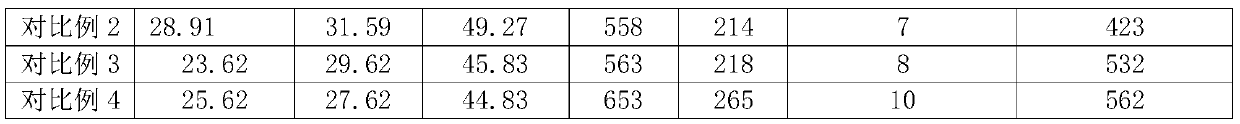

Examples

Embodiment 1

[0045] A preparation method of high anti-seepage compensation shrinkage concrete specially used for urban underground utility tunnels, comprising the following steps:

[0046] S1: Prepare the mixture: according to parts by weight, mix 10 parts of stones and 15 parts of tailings and stir evenly, then add 8 parts of cement, 1 part of fly ash, 1 part of microbeads, and 1 part of nano-mineral powder; add 0.05 part of basalt fiber, 0.08 part of polypropylene mesh fiber, 0.5 part of expansion agent, 0.1 part of cement-based osmotic crystalline material and 25 parts of sand are added, mixed evenly and then stirred for 30 seconds to obtain the mixture; among them, the cement uses 42.5 grade silicate Cement; wherein, the nano-mineral powder is nano-SiO 2 , Nano CaCO 3 , The mixture of nano clay with a weight ratio of 1:0.8:0.6;

[0047] S2: Pre-wet the mixture: add 1.2 parts of mixing water to the mixture, and stir for 50s to fully pre-wet the mixture;

[0048] S3: Preparation of mi...

Embodiment 2

[0051] A preparation method of high anti-seepage compensation shrinkage concrete specially used for urban underground utility tunnels, comprising the following steps:

[0052] S1: Prepare the mixture: according to parts by weight, mix 18 parts of stones and 20 parts of tailings and stir evenly, then add 14 parts of cement, 3 parts of fly ash, 2 parts of microbeads, and 3 parts of nano-mineral powder, add 0.12 parts of basalt fiber, 0.13 part of polypropylene mesh fiber, 2.3 parts of expansion agent, 0.6 part of cement-based osmotic crystalline material and 32 parts of sand are added, mixed evenly and then stirred for 35 seconds to obtain the mixture; among them, the cement uses 52.5 grade silicate Cement; wherein, the nano-mineral powder is nano-SiO 2 , Nano CaCO 3 , a mixture of nano clay with a weight ratio of 1:0.9:0.8;

[0053] S2: Pre-wet the mixture: add 3 parts of mixing water to the mixture and stir for 55s to fully pre-wet the mixture;

[0054] S3: Preparation of m...

Embodiment 3

[0057] A preparation method of high anti-seepage compensation shrinkage concrete specially used for urban underground utility tunnels, comprising the following steps:

[0058] S1: Preparation of mixture: according to parts by weight, mix 25 parts of stones and 25 parts of tailings and stir evenly, then add 20 parts of cement, 5 parts of fly ash, 4 parts of microbeads, and 4 parts of nano-mineral powder, add 0.2 parts of basalt fiber, 0.16 parts of polypropylene mesh fiber, 3 parts of expansion agent, 1 part of cement-based permeable crystalline material and 40 parts of sand are added, mixed evenly and then stirred for 40 seconds to obtain the mixture; among them, the cement uses 42.5 grade silicate Cement; wherein, the nano-mineral powder is nano-SiO 2 , Nano CaCO 3 , The mixture of nano clay with a weight ratio of 1:1.2:1.3;

[0059] S2: Pre-wet the mixture: add 6 parts of mixing water to the mixture and stir for 60s to fully pre-wet the mixture;

[0060] S3: Preparation o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com