Terahertz health-preserving ceramic cooking pot and manufacturing method thereof

A production method and terahertz technology, which can be used in clay products, other household appliances, applications, etc., can solve the problems of limited energy and wide frequency spectrum, and achieve the effect of enhancing physical fitness, promising market and improving human microcirculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

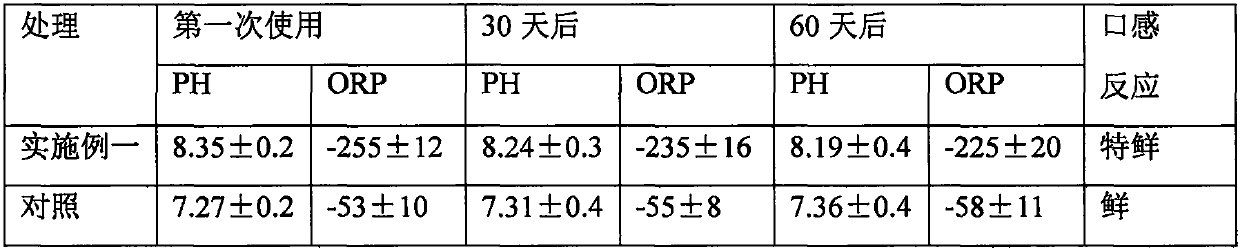

Embodiment 1

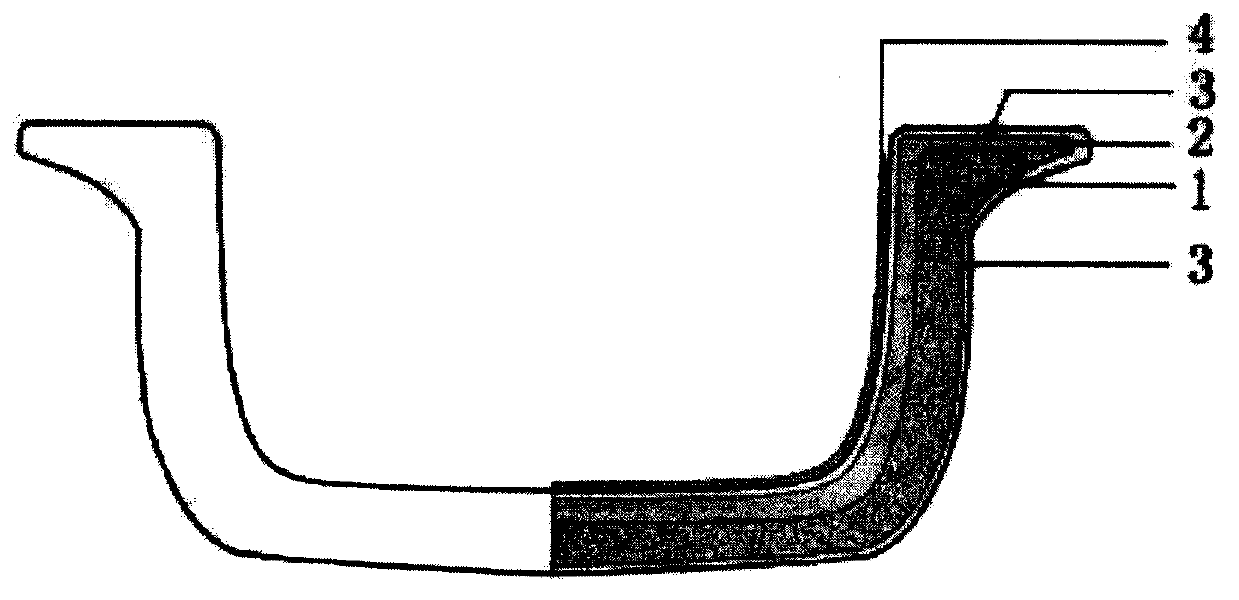

[0040] Step 1, preparation of the cauldron body: the following components in weight percentage: 60% clay, 10% Guiyang stone, 15% zeolite, 5% tourmaline, 5% purple clay, mix evenly, add terahertz active water and stir to form a blank, After being injected into the mold, it is demolded and dried, then put into the kiln and heated to 850-1050°C for 8-10 hours, and then it is gradually cooled and then exits the kiln;

[0041] Step 2, preparation of terahertz wave emission layer: components by weight percentage: 10% rutile, 25% meteorite, 30% radium stone, 15% tourmaline, 20% chrysanthemum stone, 50% kaolin, 3% resin mixed Evenly, add terahertz active water and stir it into a slurry, coat it on the inner wall of the fired and cooled cauldron, the coating thickness is 0.1-3.0mm, and dry it for later use;

[0042] Step 3, terahertz wave treatment: irradiate the cauldron coated with the terahertz wave emission layer with a frequency of 0.1-1.2THz and a wavelength of 3-20μm with terahe...

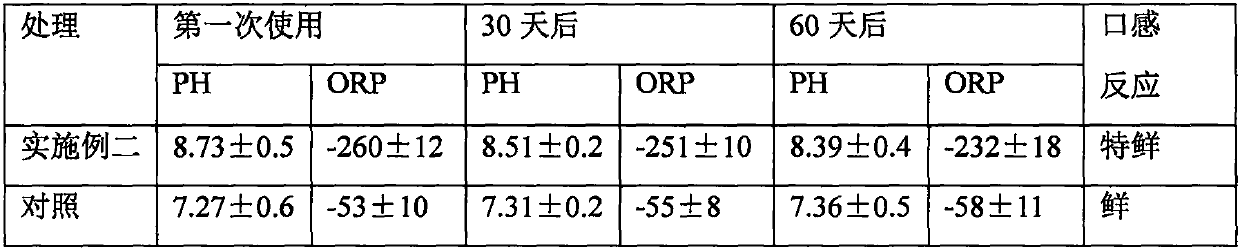

Embodiment 2

[0050] Described preparation method comprises:

[0051] Step 1, preparation of the cauldron body: the following components in weight percentage: 70% clay, 5% Guiyang stone, 10% zeolite, 15% tourmaline, 8% purple clay, mix evenly, add terahertz active water and stir to form a blank, After being injected into the mold, it is demolded and dried, then put into the kiln and heated to 850-1050°C for 8-10 hours, and then it is gradually cooled and then exits the kiln;

[0052] Step 2, preparation of terahertz wave emission layer: components by weight percentage: 15% rutile, 30% meteorite, 20% radium stone, 20% tourmaline, 25% chrysanthemum stone, 30% kaolin, 4% resin mixed Evenly, add terahertz active water and stir it into a slurry, coat it on the inner wall of the fired and cooled cauldron, the coating thickness is 0.1-3.0mm, and dry it for later use;

[0053] Step 3, terahertz wave treatment: irradiate the cauldron coated with the terahertz wave emission layer with a frequency of...

Embodiment 3

[0061] Described preparation method comprises:

[0062] Step 1, preparation of the cauldron body: the following components by weight percentage: 80% pottery clay, 15% Guiyang stone, 5% zeolite, 10% tourmaline, 3% purple clay, mix evenly, add terahertz active water and stir to form a blank, After being injected into the mold, it is demolded and dried, then put into the kiln and heated to 850-1050°C for 8-10 hours, and then it is gradually cooled and then exits the kiln;

[0063] Step 2, preparation of terahertz wave emission layer: components by weight percentage: 20% rutile, 20% meteorite, 25% radium stone, 25% tourmaline, 15% chrysanthemum stone, 40% kaolin, 5% resin mixed Evenly, add terahertz active water and stir it into a slurry, coat it on the inner wall of the fired and cooled cauldron, the coating thickness is 0.1-3.0mm, and dry it for later use;

[0064]Step 3, terahertz wave treatment: irradiate the cauldron coated with the terahertz wave emission layer with a frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com