High-temperature-resistant high-permeability wave absorbing sheet and preparation method thereof

A technology with high magnetic permeability and high temperature resistance, applied in chemical instruments and methods, electronic equipment, other household appliances, etc. The effect of high temperature resistance, high magnetic permeability and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

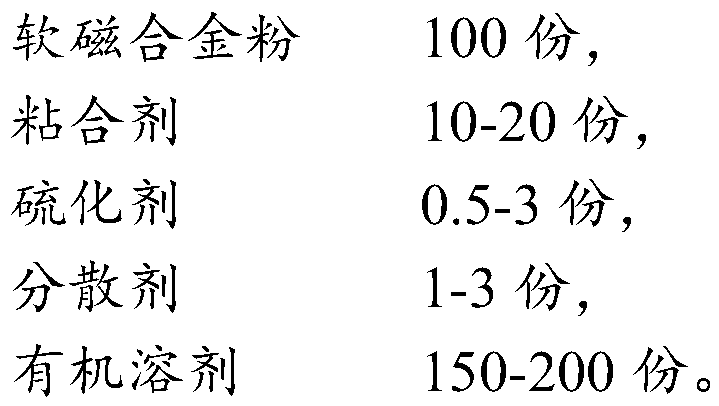

[0026] This embodiment provides a high-permeability wave-absorbing sheet with high temperature resistance and a preparation method thereof. The high-permeability wave-absorbing sheet with high temperature resistance of this embodiment comprises the following components by weight:

[0027]

[0028] Among them, the soft magnetic alloy powder is flat FeSiAl, D 50 =50-60μm, sheet thickness below 1μm; binder is nitrile rubber with 41% acrylonitrile content, Mooney viscosity 55-60; vulcanizing agent is brominated phenolic resin; dispersant is pyrophosphate dispersant; organic solvent It is ethyl acetate and butyl acetate, and the mass ratio of ethyl acetate and butyl acetate is 3:2.

[0029] The preparation method of the absorbing sheet of the present embodiment is as follows:

[0030] (1) Mix the components of the above-mentioned wave-absorbing sheet, and use a planetary mixer to stir and disperse at a medium speed, and the stirring time is 2 hours;

[0031] (2) Stir at low s...

Embodiment 2

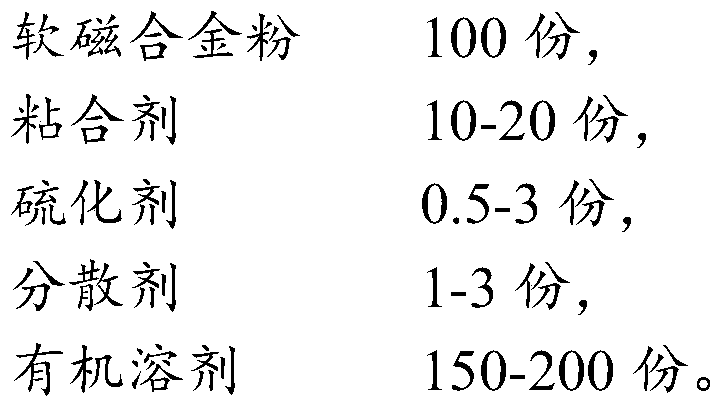

[0035] This embodiment provides a high-permeability wave-absorbing sheet with high temperature resistance and a preparation method thereof. The high-permeability wave-absorbing sheet with high temperature resistance of this embodiment comprises the following components by weight:

[0036]

[0037] Among them, the soft magnetic alloy powder is flat FeSiAl, D 50 =50-60μm, sheet thickness below 1μm; binder is nitrile rubber with 41% acrylonitrile content, Mooney viscosity 55-60; vulcanizing agent is brominated phenolic resin; dispersant is pyrophosphate dispersant; organic solvent It is ethyl acetate and butyl acetate, and the mass ratio of ethyl acetate and butyl acetate is 3:2.

[0038] The preparation method of the absorbing sheet of the present embodiment is as follows:

[0039] (1) Mix the components of the above-mentioned wave-absorbing sheet, and use a planetary mixer to stir and disperse at a medium speed for 2 hours;

[0040] (2) Stir at low speed and cooperate wit...

Embodiment 3

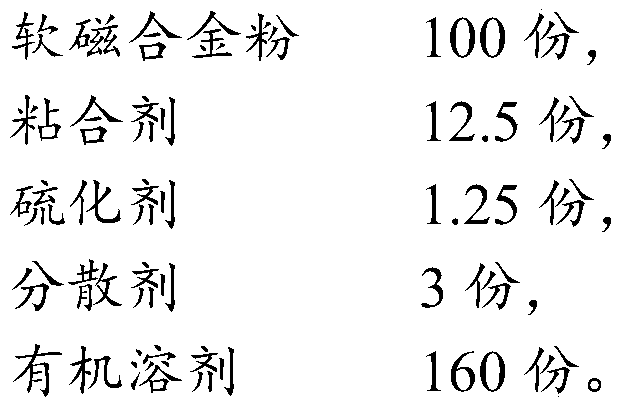

[0044] This embodiment provides a high-permeability wave-absorbing sheet with high temperature resistance and a preparation method thereof. The high-permeability wave-absorbing sheet with high temperature resistance of this embodiment comprises the following components by weight:

[0045]

[0046] Among them, the soft magnetic alloy powder is flat FeSiAl, D 50 =50-60μm, sheet thickness below 1μm; binder is nitrile rubber with 41% acrylonitrile content, Mooney viscosity 55-60; vulcanizing agent is brominated phenolic resin; dispersant is pyrophosphate dispersant; organic solvent It is ethyl acetate and butyl acetate, and the mass ratio of ethyl acetate and butyl acetate is 3:2.

[0047] The preparation method of the absorbing sheet of the present embodiment is as follows:

[0048] (1) Mix the components of the above-mentioned wave-absorbing sheet, and use a planetary mixer to stir and disperse at a medium speed for 2 hours;

[0049] (2) Stir at low speed and cooperate wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com